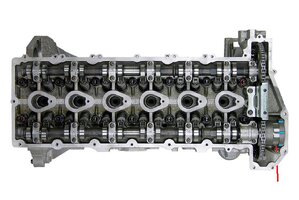

Hi. Long time lurker. I have been in the process of swapping a blown motor(hydrolocked and cracked a piston) out of a 2004 Trailblazer EXT LT 4.2l 4x4 that was given to me. Low mileage swap with brand new seals all over. I've replaced a lot of the internal parts inside as well . I did't wanna mess with this thing for awhile. Lol. In the process of finishing things up this code has been consistently coming and going. Today it started dying when coming to a stop. Started up immediately and wouldve died again but I gave it the power brake and got it back to the shop.

Got my TB on the scanner and the only code I had was P0016. Then the longer I let the truck run the more more open it would die at idle. I've worked thru everything else it could be at I believe.

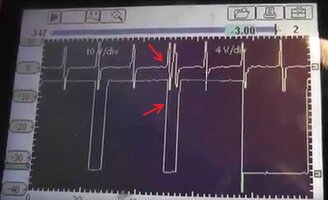

When I watch my live data for the VVT system it shows my desired is 0 and actual at 0 when the code is stored. When the code is live(pending), desired is 0 and actual will start climbing all the way to 15 degrees till the engine stalls. I attempted to see if my scan tool would let me command while it was malfunctioning but all it did was maybe make it take longer to stall out.

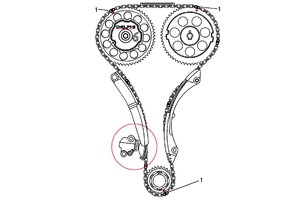

This leads me to believe that it's something internal with the cam gear.

I've been doing this professionally for 3 years. Did kind of a mentorships thing for 2 year before the three years professionally but am starting to realize my need for knowledge is either outpacing my mentors understanding or he just doesn't care anymore. He just seems to thing its an oil related issue but I don't which is why I'm here. Anywho.

Any help would be greatly appreciated.

Got my TB on the scanner and the only code I had was P0016. Then the longer I let the truck run the more more open it would die at idle. I've worked thru everything else it could be at I believe.

When I watch my live data for the VVT system it shows my desired is 0 and actual at 0 when the code is stored. When the code is live(pending), desired is 0 and actual will start climbing all the way to 15 degrees till the engine stalls. I attempted to see if my scan tool would let me command while it was malfunctioning but all it did was maybe make it take longer to stall out.

This leads me to believe that it's something internal with the cam gear.

I've been doing this professionally for 3 years. Did kind of a mentorships thing for 2 year before the three years professionally but am starting to realize my need for knowledge is either outpacing my mentors understanding or he just doesn't care anymore. He just seems to thing its an oil related issue but I don't which is why I'm here. Anywho.

Any help would be greatly appreciated.

Last edited:

connect up one of your spare vvt but not installed... ie, let it sit in "thin air"... of course away from any bad things like belts and such. Leave a disconnected vvt installed in the engine. What happens? I don't know whether the engine will run in some default mode but maybe you will get some differences in data or otherwise that might lead to something.

connect up one of your spare vvt but not installed... ie, let it sit in "thin air"... of course away from any bad things like belts and such. Leave a disconnected vvt installed in the engine. What happens? I don't know whether the engine will run in some default mode but maybe you will get some differences in data or otherwise that might lead to something.