Hello, my name is Rick, from just outside Columbia, SC. I hope you don't mind me joining your club!

I am semi-retired and am looking for a car hobby. I'm fascinated by these inline sixes, and have purchased a few different year model Trailblazers: nice cars with mechanical issues. That's my sweet spot, as I am incapable of performing satisfactory body/paint work!

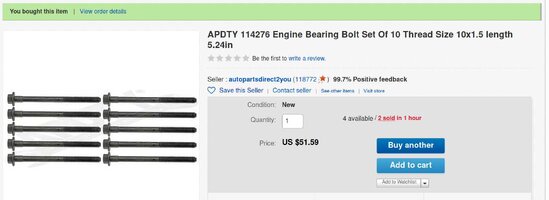

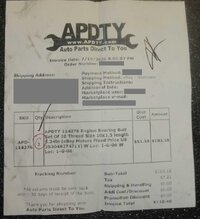

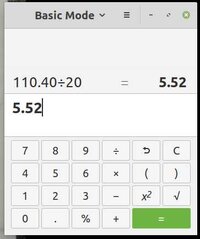

I have a daughter who intends to be a licensed driver at years end. I have purchased a nice 2006 that has a rod knock. My aim is to pull the motor and have a look at the rod and crank bearings, then decide the best course of remedy. I have additionally purchased another Trailblazer at government auction. It's a 2005 with 125k on the clock. Dunno what I'll do with it at the moment. I may get the chassis and drive train ready to swap under a future (classic body) project, or the engine may simply be a donor for the daughter's 2006. Anyway, I am starting a collection around these vehicles and found this forum to use as a reference for consultation. Speaking of which... Here are a few beginners questions:

In looking for additional resources. Are their other places (websites, forums, ect.) I should know about that have information and active participation in LL8 discussions?

I have searched this forum and have created a (very) basic understanding of the various differences in the LL8 year models. Allow me to test my studies: At this time, my understanding is that the 2008 and 2009 engines are in their own category for swapping, due to the crank sensor and communications strategy. The 2004-2007 engines can be swapped at will, as long as the PCM corresponding to the installed engine is used. Does that sum things up?

I look forward to restoring some of these vehicles, possibly flipping a few just for fun and practice. I'm willing to share with you about anything I can, but I'm pretty sure most of you know more than I do, so I'll sign off with a thanks, and I look forward to hearing from you.

I am semi-retired and am looking for a car hobby. I'm fascinated by these inline sixes, and have purchased a few different year model Trailblazers: nice cars with mechanical issues. That's my sweet spot, as I am incapable of performing satisfactory body/paint work!

I have a daughter who intends to be a licensed driver at years end. I have purchased a nice 2006 that has a rod knock. My aim is to pull the motor and have a look at the rod and crank bearings, then decide the best course of remedy. I have additionally purchased another Trailblazer at government auction. It's a 2005 with 125k on the clock. Dunno what I'll do with it at the moment. I may get the chassis and drive train ready to swap under a future (classic body) project, or the engine may simply be a donor for the daughter's 2006. Anyway, I am starting a collection around these vehicles and found this forum to use as a reference for consultation. Speaking of which... Here are a few beginners questions:

In looking for additional resources. Are their other places (websites, forums, ect.) I should know about that have information and active participation in LL8 discussions?

I have searched this forum and have created a (very) basic understanding of the various differences in the LL8 year models. Allow me to test my studies: At this time, my understanding is that the 2008 and 2009 engines are in their own category for swapping, due to the crank sensor and communications strategy. The 2004-2007 engines can be swapped at will, as long as the PCM corresponding to the installed engine is used. Does that sum things up?

I look forward to restoring some of these vehicles, possibly flipping a few just for fun and practice. I'm willing to share with you about anything I can, but I'm pretty sure most of you know more than I do, so I'll sign off with a thanks, and I look forward to hearing from you.