JayArr

Member

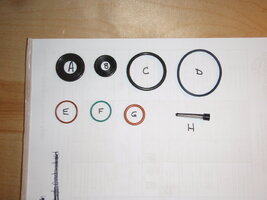

I finished disassembly this weekend including all the clutch packs. The casting is soaking in the parts washing tank and I've laid out all the parts on the bench.

Next step is to remove all the bushings. Brad (youtube) uses a bit in a pneumatic chisel, I'll have to figure out if I can buy that or if it's a custom grind.

I'll also order the initial rebuild kit this week, one of the clutches was pretty burnt so I'll order the kit that includes new steels. I'll also replace the bonded pistons and a few other components.

Looking at my parts washer I realize it's not good enough to clean the internal parts, it's pretty dirty. I'm running the current solvent through one of those sand bags to clean it up and I think it's time to do the "external oil filter" mod to the tank so that it stays clean.

JayArr

Next step is to remove all the bushings. Brad (youtube) uses a bit in a pneumatic chisel, I'll have to figure out if I can buy that or if it's a custom grind.

I'll also order the initial rebuild kit this week, one of the clutches was pretty burnt so I'll order the kit that includes new steels. I'll also replace the bonded pistons and a few other components.

Looking at my parts washer I realize it's not good enough to clean the internal parts, it's pretty dirty. I'm running the current solvent through one of those sand bags to clean it up and I think it's time to do the "external oil filter" mod to the tank so that it stays clean.

JayArr