I hoped that someone had already tried this, but it seems no one has gone through it on a trailblazer. There are write ups for jeeps and explorers and pickups, but none that I can find for the SWB TB. So here it is:

Remove the rear driver side seat bottom bracket nuts with a deep 18mm socket.

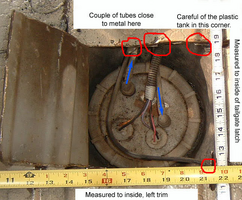

From the middle of the two studs go forward until you feel a body seam running across the floor. This is the approximate center point of the pump assembly. Make a small cut so you can feel under the carpet to find the seam. Be careful to make a shallow cut since there are wiring harnesses in several places under the carpet. You will have to cut the carpet above this point in a three inch radius so it's larger than the top of the pump - the opening should be at least six inches wide.

Cut the metal beneath a similar size. Be very careful as there is very little distance to the tank - my fingers could barely fit between the body and the tank. Don't use a jig saw. Probably a dremel with a metal cutting disk would be best.

From this point continue with the regular fuel pump replacement procedure.

Why should you do this?

If you ever have a problem with the pump or sender the repair will be quick and easy. If you have no way to lift the truck so you can get under it and lower the tank, then you might want to try it.

Why did I not do it?

The hole is directly under the passenger's feet. Not only will you have the carpet cut up in a visible area but you will need to make a fairly robust plate to cover the hole in the floor. If you don't mind throwing a floor mat over it to cover it up then you'll be fine.

Remove the rear driver side seat bottom bracket nuts with a deep 18mm socket.

From the middle of the two studs go forward until you feel a body seam running across the floor. This is the approximate center point of the pump assembly. Make a small cut so you can feel under the carpet to find the seam. Be careful to make a shallow cut since there are wiring harnesses in several places under the carpet. You will have to cut the carpet above this point in a three inch radius so it's larger than the top of the pump - the opening should be at least six inches wide.

Cut the metal beneath a similar size. Be very careful as there is very little distance to the tank - my fingers could barely fit between the body and the tank. Don't use a jig saw. Probably a dremel with a metal cutting disk would be best.

From this point continue with the regular fuel pump replacement procedure.

Why should you do this?

If you ever have a problem with the pump or sender the repair will be quick and easy. If you have no way to lift the truck so you can get under it and lower the tank, then you might want to try it.

Why did I not do it?

The hole is directly under the passenger's feet. Not only will you have the carpet cut up in a visible area but you will need to make a fairly robust plate to cover the hole in the floor. If you don't mind throwing a floor mat over it to cover it up then you'll be fine.

Last edited: