Sparky said:

OK, yeah that's the PWM. The voltage can't go above the voltage output of the alternator (which shouldn't go above 14.5 or so), but the PWM signal can and does kill bulbs faster than a steady voltage.

PWM waveforms can be damaging, but not because the voltage flies up higher than the alternator's max. It's the excessive switching on and off, hundreds of times a second, that causes issues. An incandescent lamp has a filament that glows white-hot. But when it turns off, it takes a large fraction of a second to get cold and go dark. Switching that sort of load on and off faster than the filament's mass can react, and faster than the eye can see, is no problem. And that's what the GMT360 designers intended to have for headlights.

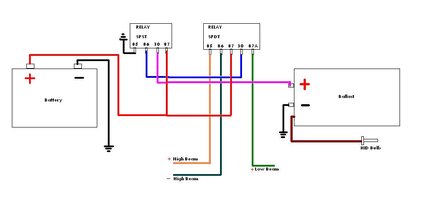

The electronic ballast of HIDs wasn't designed for the fast on/off switching, and there are inductors inside the units that demand excessive current when switched too fast for their design. That damages the electronics, can burn them out, and the pulses of excess current can overheat connectors.

But it's my nature to correct the misperception that the PWM signal can create voltage spikes.

Any LED lamp with a built-in current stabilizer circuit can also be designed to work with PWM signals, but I suspect most of them are cheap and don't. That's why some LEDs can burn out. Trailblazers didn't have DRL circuits for running lights, just the headlights, IIRC. Full-size platforms do.

The 4114 incandescent lamp issue was a separate one, as far as I can tell, of the old 3156 incandescent lamps not having a filament rated for the newer alternator setpoints of over 14V. A filament running at hotter than expected temps MIGHT be more sensitive to a slower PWM signal, perhaps not causing visible flickering due to the persistence of vision, but enough to vibrate the filament (which acts as a tiny inductor due to its coil shape.). A vibrating filament will have a shorter life.

It's super annoying seeing most people drive with only one burnt out.

It's super annoying seeing most people drive with only one burnt out.