Hello everyone, so my 2003 Silverado is having an issue with a long crank. Have to turn the key for about 3-5 seconds until it eventually turns over. I've replaced the injectors, pump (twice), spark plugs and wires, fuel pressure regulator, and the fuel filter. I've taken it to two mechanics, the first one said that my new pump wasn't good or building enough pressure to turn over, so I replaced it the second time. He also said I have a minor head gasket leak. I took it to a second mechanic after the first one blew me off for 2 weeks, they said there was no head gasket leak. Sometimes it starts fine in the morning no problem, other times it has a long crank after running into the store for 15 minutes. Priming the fuel system doesn't seem to make a difference. My last idea may be the camshaft sensor however if anyone may have a different idea please let me know. Thank you

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NEED HELP 5.3 vortec long crank

- Thread starter Kgurn1020

- Start date

Sounds like a fuel pressure regulator problem to me. If I am remembering correctly, its on one of the fuel rails.

I can give it a shot, however I had already replaced the regulator, even pulled the vacuum line off to see if fuel leaked out, was dry as a boneSounds like a fuel pressure regulator problem to me. If I am remembering correctly, its on one of the fuel rails.

Then I would start with renting a fuel pressure test kit from your local parts store.

The fuel pressure either is not building, or is being bypassed.

When you replaced you fuel pump, did you replace the assembly, or just the fuel pump on the assembly?

Also, are you replacing the parts with off-brand parts, or name brand?

The fuel pressure either is not building, or is being bypassed.

When you replaced you fuel pump, did you replace the assembly, or just the fuel pump on the assembly?

Also, are you replacing the parts with off-brand parts, or name brand?

I have a fuel pressure test kit, hooking it up I believe sat just above 50psi or 55, can't remember off the top of my head. Removing the pressure regulator the psi was at 60 at idle, so I don't believe it is the pump. replaced the entire assembly with the pump as well.Then I would start with renting a fuel pressure test kit from your local parts store.

The fuel pressure either is not building, or is being bypassed.

When you replaced you fuel pump, did you replace the assembly, or just the fuel pump on the assembly?

Also, are you replacing the parts with off-brand parts, or name brand?

Check engine light is on, has the P0420 and P0430 catalyst code, I believe this is due to the fact that previous owner had cut the cats out. The pressure after it primes stays. And as I had said before that some times it starts perfectly fine even without a prime, including over nightI have to ask an obvious question, any check engine lights?

Mooseman

Moderator

Sorry, I don't have any ideas beyond a fuel pressure issue.

Any difference between cold start and hot start?

Is your truck Flex-Fuel capable? Once saw something about the alcohol content sensor needing re-calibrating.

And also found this:

www.silveradosierra.com

www.silveradosierra.com

Any difference between cold start and hot start?

Is your truck Flex-Fuel capable? Once saw something about the alcohol content sensor needing re-calibrating.

And also found this:

Intermitent Long Start Cranking

I do not have the flex fuel variant. I have yet to really find a pattern, as this morning was roughly 40 degrees and the truck started fine, and started fine parked on a hill during the afternoon. But then, a few hours later, it had the long crank again. It seems to always start the second time immediately after the first, but that seems to be the only patternSorry, I don't have any ideas beyond a fuel pressure issue.

Any difference between cold start and hot start?

Is your truck Flex-Fuel capable? Once saw something about the alcohol content sensor needing re-calibrating.

And also found this:

Intermitent Long Start Cranking

www.silveradosierra.com

Typically... Long Cranking Scenarios -Fail-2-Start can often be traced back to having, Poor, Broken or Disconnected GROUNDS or BONDING STRAPS. IIANM... the 2003 Vintage Silverado has TWO Engine Grounds: One on the Passenger Side Rear Engine Head leading to the Fire-Wall ...and One at the Battery Negative Connection located along the Lower Driver's Side of the Engine Block.

Galvanic Corrosion between Dissimilar Metals is THE Cause and Origin for Bad Block, Grounds. Inspect, Remove, "Clean Them Down to a GLEAM" and then apply a small dollop of Dielectric Grease in between the Eyelet, Fastener Bolt Face and the Block Surfaces and SNUG them all Down. Replace any that are GREEN or FRAYED with Brand New Straps available on Amazon.

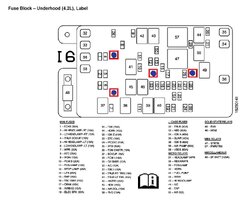

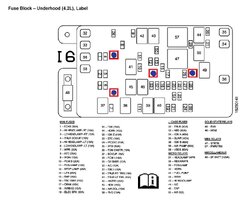

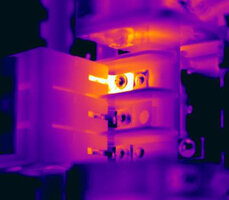

One other place worth checking because of its thermodynamic implications (Very Cold Weather) issues is to Tighten Down the Four Galvanized Bolt Posts holding the Under-Fuse Block Assemblies snugly up against the insert pins of the upper Fuse Box Fuse Panel. Sometimes... Weird Start-No-Start issues like these can yield themselves to a solution by using a Bright Flashlight, a "Graduated Eye-Ball" and enough suspicion to check them all out Very Carefully.

In some instances...the 20 AWG Copper Right Angle Bends nested inside the Fuse Box can FRACTURE and make occasional contact ...and then separate and cause an electrical BREAK in between the segments as well:

Galvanic Corrosion between Dissimilar Metals is THE Cause and Origin for Bad Block, Grounds. Inspect, Remove, "Clean Them Down to a GLEAM" and then apply a small dollop of Dielectric Grease in between the Eyelet, Fastener Bolt Face and the Block Surfaces and SNUG them all Down. Replace any that are GREEN or FRAYED with Brand New Straps available on Amazon.

One other place worth checking because of its thermodynamic implications (Very Cold Weather) issues is to Tighten Down the Four Galvanized Bolt Posts holding the Under-Fuse Block Assemblies snugly up against the insert pins of the upper Fuse Box Fuse Panel. Sometimes... Weird Start-No-Start issues like these can yield themselves to a solution by using a Bright Flashlight, a "Graduated Eye-Ball" and enough suspicion to check them all out Very Carefully.

In some instances...the 20 AWG Copper Right Angle Bends nested inside the Fuse Box can FRACTURE and make occasional contact ...and then separate and cause an electrical BREAK in between the segments as well:

Last edited:

I shall look into both of these possibilities and get back to you as soon as possible, probably start with the grounding strapsTypically... Long Cranking Scenarios -Fail-2-Start can often be traced back to having, Poor, Broken or Disconnected GROUNDS or BONDING STRAPS. IINM... the 2003 Vintage Silverado has TWO Engine Grounds: One on the Passenger Side Rear Engine Head leading to the Fire-Wall ...and One at the Battery Negative Connection located along the Lower Driver's Side of the Engine Block.

Galvanic Corrosion between Dissimilar Metals is THE Cause and Origin for Bad Block, Grounds. Inspect, Remove, "Clean Them Down to a GLEAM" and then apply a small dollop of Dielectric Grease in between the Eyelet, Fastener Bolt Face and the Block Surfaces and SNUG them all Down. Replace any that are GREEN or FRAYED with Brand New Straps available on Amazon.

One other place worth checking because of its thermodynamic implications (Very Cold Weather) issues is to Tighten Down the Four Galvanized Bolt Posts holding the Under-Fuse Block Assemblies snugly up against the insert pins of the upper Fuse Box Fuse Panel. Sometimes... Weird Start-No-Start issues like these can yield themselves to a solution by using a Bright Flashlight, a "Graduated Eye-Ball" and enough suspicion to check them all out Very Carefully.

In some instances...the 20 AWG Copper Right Angle Bends nested inside the Fuse Box can FRACTURE and make occasional contact ...and then separate and cause an electrical BREAK in between the segments as well:

View attachment 114839View attachment 114840View attachment 114841View attachment 114842

After looking over the fuel system just one more time, I believe the fuel pressure regulator was somehow faulty, it was holding vacuum, but the 80$ part wouldn't completely seat in the fuel rail. I reinstalled the factory since nothing was wrong with it and seems like I gained an additional 5 psi. However, hooking up my fuel pressure gauge, I noticed that after 15 minutes, I lost 18 psi. Where else could the pressure drain from? And what's the acceptable pressure drop rate?

Check on your version of the Fuel Pump as either being a Dual (In-Flow and Return) set up...or if of a Later Model Design...having only the Single Output Pressure line that is managed inside of the Fuel Pump with an INTERNAL CHECK VALVE.

If that portion of the system has a Failing Check Valve...then whatever Fluid Pressure manages to finally reach all the way down the full length of the Fuel Line up to the Fuel Rail,,, will suffer with a Fuel Pressure Loss that should only gradually diminish over time.

There IS another issue that can occur if the Pintle Valve in a particular EFi is NOT completely closing... it can leak down the in-line Fuel Pressure left over when the Fuel Pump is OFF.

If this is the Case... you might have elevated CAT Converter Temps present while trying to burn off extra Raw Fuel being dumped into the Cylinder(s) since only Atomized Fuel will Mix with Air and properly combust in the engine cylinders. You will also notice a Fresh Gasoline Smell after pulling the Engine Oil Dipstick as the Fresh Fuel can leak past the involved Piston Rings and contaminate the Engine Oil in the Crank-Case Oil-Pan.

If that portion of the system has a Failing Check Valve...then whatever Fluid Pressure manages to finally reach all the way down the full length of the Fuel Line up to the Fuel Rail,,, will suffer with a Fuel Pressure Loss that should only gradually diminish over time.

There IS another issue that can occur if the Pintle Valve in a particular EFi is NOT completely closing... it can leak down the in-line Fuel Pressure left over when the Fuel Pump is OFF.

If this is the Case... you might have elevated CAT Converter Temps present while trying to burn off extra Raw Fuel being dumped into the Cylinder(s) since only Atomized Fuel will Mix with Air and properly combust in the engine cylinders. You will also notice a Fresh Gasoline Smell after pulling the Engine Oil Dipstick as the Fresh Fuel can leak past the involved Piston Rings and contaminate the Engine Oil in the Crank-Case Oil-Pan.

Last edited:

The fuel pump has 3 outlets

im not an expert on fuel systems, however I know that my pump has 3 outlets, I have the '03 5.3 z71 non flex fuel. The original pump would drop pressure immediately, now on my third pump and the pressure drop is substantially lower over time, which leads me to believe that it is not a fuel pump failure. This is the current pump installed in the vehicleCheck on your version of the Fuel Pump as either being a Dual (In-Flow and Return) set up...or if of a Later Model Design...having only the Single Output Pressure line that is managed inside of the Fuel Pump with a INTERNAL CHECK VALVE.

If that portion of the system has a Failing Check Valve...then whatever Fluid Pressure manages to finally reach all the way down the full length of the Fuel Line up to the Fuel Rail,,, will suffer with a Fuel Pressure Loss that should only gradually diminish over time.

There IS another issue that can occur if the Pintle Valve in a particular EFi is NOT completely closing... it can leak down the in-line Fuel Pressure left over when the Fuel Pump is OFF.

If this is the Case... you might have elevated CAT Converter Temps present while trying to burn off extra Raw Fuel being dumped into the Cylinder(s) since only Atomized Fuel will Mix with Air and properly combust in the engine cylinders. You will also notice a Fresh Gasoline Smell after pulling the Engine Oil Dipstick as the Fresh Fuel can leak past the involved Piston Rings and contaminate the Engine Oil in the Crank-Case Oil-Pan.

Precision Fuel Sending Unit/Assembly - A30025

It is almost "Religious Doctrine" across the board here at GMT Nation... for any and all GM and GMC products to use either the Bosch or the ACDelco versions for their Fuel Pump Replacements.

RockAuto is a great place to shop and compare... and of ALL the components used and stressed by the very nature of how hard they must work to keep these Engines running... The Fuel Pump is right at the top of that list:

Be Certain...to Check YOUR RPO Code (Label inside the Glove Box via the Aluminized Sticker) to make the Right Choice from this List:

RockAuto is a great place to shop and compare... and of ALL the components used and stressed by the very nature of how hard they must work to keep these Engines running... The Fuel Pump is right at the top of that list:

Be Certain...to Check YOUR RPO Code (Label inside the Glove Box via the Aluminized Sticker) to make the Right Choice from this List:

2003 CHEVROLET SILVERADO 1500 5.3L V8 Fuel Pump & Housing Assembly | Shop Now at RockAuto

Fuel & Air Parts and More for Your 2003 CHEVROLET SILVERADO 1500 at Reliably Low Prices. Fast Online Catalog. DIY-Easy. Your Choice of Quality. Full Manufacturer Warranty.

www.rockauto.com

Believe me, I normally always use genuine gm parts. This is my daily driver and took a risk on this pump due to time constraints. for almost 200$ I figured it would at least meet the requirements. I'll look into it further and see if it could possibly be leaking somewhere else, possibly injectors.It is almost "Religious Doctrine" across the board here at GMT Nation... for any and all GM and GMC products to use either the Bosch or the ACDelco versions for their Fuel Pump Replacements.

RockAuto is a great place to shop and compare... and of ALL the components used and stressed by the very nature of how hard they must work to keep these Engines running... The Fuel Pump is right at the top of that list:

Be Certain...to Check YOUR RPO Code (Label inside the Glove Box via the Aluminized Sticker) to make the Right Choice from this List:

View attachment 114853

Mooseman

Moderator

Being an 03, it should be a return system, hence the external engine mounted pressure regulator.

Here's some things you could do to try and isolate where the pressure leakage is happening. After the pump has primed, pinch the fuel line coming from the pump. If it still leaks, it could be the pressure regulator or injectors. Unpinch the line in and re-prime the pump. Pinch the return line. If pressure still drops, I would suspect an injector. Unpinch the return line and prime the system once more. Pinch both lines. If pressure still drops, then it's certain to be an injector as there is nowhere else for the fuel to go except an external leak.

Here's some things you could do to try and isolate where the pressure leakage is happening. After the pump has primed, pinch the fuel line coming from the pump. If it still leaks, it could be the pressure regulator or injectors. Unpinch the line in and re-prime the pump. Pinch the return line. If pressure still drops, I would suspect an injector. Unpinch the return line and prime the system once more. Pinch both lines. If pressure still drops, then it's certain to be an injector as there is nowhere else for the fuel to go except an external leak.

I'll do that and let you know once I lift the bed and have access to the pump (again). Hoping this solves the issues im having as I also got the P0300 code today. (Have new injectors and plugs not sure why this code showed up other than the possible start up issue with the pump)Being an 03, it should be a return system, hence the external engine mounted pressure regulator.

Here's some things you could do to try and isolate where the pressure leakage is happening. After the pump has primed, pinch the fuel line coming from the pump. If it still leaks, it could be the pressure regulator or injectors. Unpinch the line in and re-prime the pump. Pinch the return line. If pressure still drops, I would suspect an injector. Unpinch the return line and prime the system once more. Pinch both lines. If pressure still drops, then it's certain to be an injector as there is nowhere else for the fuel to go except an external leak.

The first thing to try is to use either Starter Fluid Spray or Carb Cleaner...VERY JUDICIOUSLY...AND WITH A FIRE EXTINGUISHER CLOSE AT HAND... And use the directions of the edges of the Intake Manifold as your Target of Opportunity.

With the Parking Brake SET ...and the Engine at Idle... Very Lightly Spray around the IM Perimeter (include the BACK of the IM near the Fire-Wall) and then --Listen-- for Engine RPM to INCREASE. It is very important --NOT-- to Over-Do this P0300 Diagnostic Technique...especially inside of any enclosed Garage.

The same approach can be done using Propane...but the Risks for Engine Damage and Burning Off your Eye-Brows is even greater. If you Hear the Engine RPM Pick UP... then the issue becomes clear for the need to R&R the Intake Manifold and Replace the Gaskets (Hopefully with their Updated Flavor).

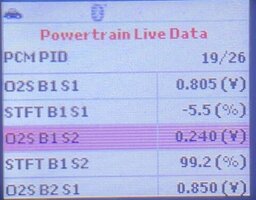

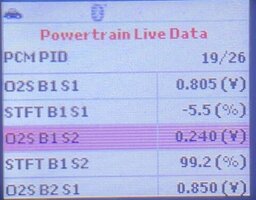

You can re-visit these PIDs after performing any necessary repairs and compare the results. If the above Test reveals NO Changes in RPM... Consulting with @TJBaker57 and @budwich about the implications of Weird Short Term Fuel Trim Issues vs. an Errant O2 Sensor will help. I modified your image from just above to be more easily viewed:

With the Parking Brake SET ...and the Engine at Idle... Very Lightly Spray around the IM Perimeter (include the BACK of the IM near the Fire-Wall) and then --Listen-- for Engine RPM to INCREASE. It is very important --NOT-- to Over-Do this P0300 Diagnostic Technique...especially inside of any enclosed Garage.

The same approach can be done using Propane...but the Risks for Engine Damage and Burning Off your Eye-Brows is even greater. If you Hear the Engine RPM Pick UP... then the issue becomes clear for the need to R&R the Intake Manifold and Replace the Gaskets (Hopefully with their Updated Flavor).

You can re-visit these PIDs after performing any necessary repairs and compare the results. If the above Test reveals NO Changes in RPM... Consulting with @TJBaker57 and @budwich about the implications of Weird Short Term Fuel Trim Issues vs. an Errant O2 Sensor will help. I modified your image from just above to be more easily viewed:

Last edited:

Mooseman

Moderator

If it's misfiring, the crank sensor is sensing that one or more of the cylinders are not contributing as much as the others, sensing the slowdown on a cylinder. O2 sensor not involved.

So your STFT is -5.5. Not terrible but it is pulling fuel a little because it thinks it's running rich a little. It could be the O2 sensor is getting tired and lazy. What's the LTFT?

So your STFT is -5.5. Not terrible but it is pulling fuel a little because it thinks it's running rich a little. It could be the O2 sensor is getting tired and lazy. What's the LTFT?

If it's misfiring, the crank sensor is sensing that one or more of the cylinders are not contributing as much as the others, sensing the slowdown on a cylinder. O2 sensor not involved.

So your STFT is -5.5. Not terrible but it is pulling fuel a little because it thinks it's running rich a little. It could be the O2 sensor is getting tired and lazy. What's the LTFT?

what the heck is "99%" for a trim value??? I would say that it just tried to dump a whole lot of fuel into something on that side. Not sure how that is being read but anything over 25% (plus or minus) should have caused a "running lean/rich code"... at least that is my read.View attachment 114857

I know this is a bit unrelated to The long crank, but as for the p0300, does this mean my Bank 1 S2 sensor is failing? This photo was taken around 1300 rpm so the voltage should be much higher correct?

I would think that o2 has an issue or the wiring is "marginal"... IF the reader is functioning.

As for your question about the "higher value" because of the rpm, there is a difference between the reported voltage of an O2 and the resulting fuel trim. The fuel trims are "posted" relative to "zero %" meaning no corrective action by the trim is introduced. The voltage on the other hand is only positive, running between 0 and .9 volts nominally. You need to graph the live data to be able to watch how the system is responding at a given period of time.... your reader should be capable of that.

Last edited:

Mooseman

Moderator

I was eating too many halloween candies...  As Mooseman said, it is fuel trim from the b2 is probably "fake". The numbers from both sides should be similar looking.

As Mooseman said, it is fuel trim from the b2 is probably "fake". The numbers from both sides should be similar looking.

Your second post of LTFT seem to indicate a side "difference" with B2 appearing to be running bit lean as the system is adding fuel (both trims are positive) which the B1 side appear to "normal" (near zero... although again in real time, short term trim "oscillate" while long terms are relatively stable depending on engine / throttle "constantness".

The ECT (coolant temp) wasn't up to "normal" so potentially the system may try to enrich things. Then, the question might be is why the other side isn't doing the same.

As Mooseman said, it is fuel trim from the b2 is probably "fake". The numbers from both sides should be similar looking.

As Mooseman said, it is fuel trim from the b2 is probably "fake". The numbers from both sides should be similar looking.Your second post of LTFT seem to indicate a side "difference" with B2 appearing to be running bit lean as the system is adding fuel (both trims are positive) which the B1 side appear to "normal" (near zero... although again in real time, short term trim "oscillate" while long terms are relatively stable depending on engine / throttle "constantness".

The ECT (coolant temp) wasn't up to "normal" so potentially the system may try to enrich things. Then, the question might be is why the other side isn't doing the same.

Last edited:

hello everyone, didn't want to leave this thread unanswered, so figured I'd give an update. Decided to bring the truck to the mechanic. He told me the misfire code is due to the engine being worn, and misfiring in all cylinders . I tend to disagree due to the fact that it just immediately started after replacing the plugs and the engine has 180k, mostly highway. When I get the truck back, I will put the old plugs back in and diagnose again. They are still working on the long crank issue and will update when I have answers.

Tried explaining that this is a new issue, and it's definitely not a coincidence that immediately after replacing the plugs the issue arose. The trucks in good shape, and both previous owners kept an entire record of receipts of on time oil changes and regular maintenance. These engines last far longer than 180k before misfiring over "wear and tear" 180k is just getting broken in lol. Perhaps I got faulty plugs, or something else. Good thing I kept the previous plugsI would not want to take my 2004 LS to him. Miles on the clock show 218k.

Hello everyone, back with another update. Truck was at the mechanic for 9 days, they allegedly started it up everyday, never once had noticed the long crank issue. But within 2 days of having the truck back the issue reared its head again. I've noticed that, with the mornings here now being in the 20s-30s, the engine starts fine more often than not. It's when the temperature outside is warmer (40s and above) that the long crank issue shows up. I am beginning to think it may be a grounding issue. Maybe one of the engine grounds are old and need to be replaced. The mechanic also stated that the misfire was probably due to engine wear, however, after replacing the spark plug wires with OEM acdelcos, the code went away and seems to be running fine. Mechanic also preformed a crankshaft and camshaft sensor relearn, didn't solve the long start issue

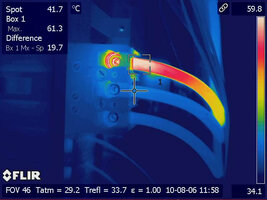

Agree... If you find anything that looks like THIS...

Be concerned that "The Color GREEN will ALWAYS Mean" that the normally superior electrical conductivity of Copper... (CU) Changes quite dramatically into a --DIELECTRIC-- once combined with atmospheric Oxygen as "Cupric Oxide". This image above shows only a --fraction-- of just how much GREEN Corrosion has actually infected along the length of those Braided Copper Strands.

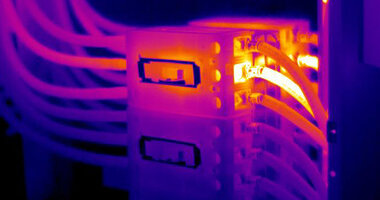

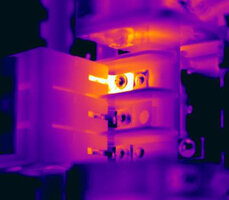

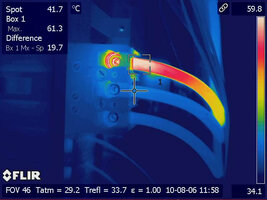

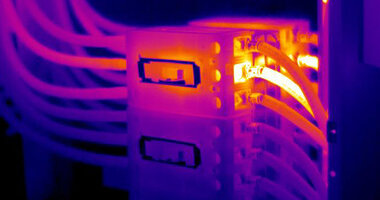

The amount of Resistance to the Current Flow caused by Cu2O is more than one might imagine because the energy trying to get past this RESISTANCE gets converted into --HEAT-- by a process known as PTC (Positive Thermal Co-Efficient) easily detectable using an Infra-Red FLIR Camera as per these images:

Don't ignore the Two Electrical Hook Ups for the Starter Motor-Solenoid as well... Sometimes...Over-Tightened Eyelet Fasteners can OVER-TURN inside of the Starter, breaking the internal wire connections to the solenoid or the motor at the Positive B+ locations. Likewise... Under-Tightened Fasteners at both positions can also invite increased resistance as well.

Visit @Realism 's Epic "GROUNDS" Thread for more complete information on this GMT360 Platform for Ground Locations:

gmtnation.com

gmtnation.com

Be concerned that "The Color GREEN will ALWAYS Mean" that the normally superior electrical conductivity of Copper... (CU) Changes quite dramatically into a --DIELECTRIC-- once combined with atmospheric Oxygen as "Cupric Oxide". This image above shows only a --fraction-- of just how much GREEN Corrosion has actually infected along the length of those Braided Copper Strands.

The amount of Resistance to the Current Flow caused by Cu2O is more than one might imagine because the energy trying to get past this RESISTANCE gets converted into --HEAT-- by a process known as PTC (Positive Thermal Co-Efficient) easily detectable using an Infra-Red FLIR Camera as per these images:

Don't ignore the Two Electrical Hook Ups for the Starter Motor-Solenoid as well... Sometimes...Over-Tightened Eyelet Fasteners can OVER-TURN inside of the Starter, breaking the internal wire connections to the solenoid or the motor at the Positive B+ locations. Likewise... Under-Tightened Fasteners at both positions can also invite increased resistance as well.

Visit @Realism 's Epic "GROUNDS" Thread for more complete information on this GMT360 Platform for Ground Locations:

Electrical Ground locations

While troubleshooting a bad ground I came across some scans of the service manual regarding electrical ground locations for our platform posted on another site. This includes both short and long wheel base, as well as both 4.2L and 5.3L. Credit goes to Wex...

Last edited:

Merry Christmas everyone, so a couple of updates. Sent the truck to another shop that specialized in Chevy trucks, they did a deep cleaning with seafoam to remove the carbon build up in the engine, seemed to have fixed the misfiring issue. As for the long crank, I still haven't solved it, I have a new daily driver and will leave the truck for a week and it'll start up, but leave it for 15 minutes after and it'll come back. I'll keep troubleshooting and hopefully solve the issue

@Kgurn1020

For curiosity sake, what is your engine code?

I am wondering if we have similar engines. Mine is a 2005 LM7, engine VIN "T".

I have somewhere around 240 thousand miles on it.

For curiosity sake, what is your engine code?

I am wondering if we have similar engines. Mine is a 2005 LM7, engine VIN "T".

I have somewhere around 240 thousand miles on it.

How do you know this.... you looked at the misfire counts?eemed to have fixed the misfiring issue.

lukedog069

Member

check to see if your cam sensor is rust jacked out of the block. this creates too big of an air gap and an extended crank.check out Eric o. youtube channel.south main auto.

Mooseman

Moderator

Maybe not rust jacked since the head is aluminum, but the sensor could be full of crud. But in either instance, shouldn't it throw a code?

lukedog069

Member

the bracket that holds in the sensor in gets rust behind it. look on YouTube and search chevy Silverado with very extended crank. eric o. is the best mechanic on youtube and should be watched by anyone looking to work on his own car.