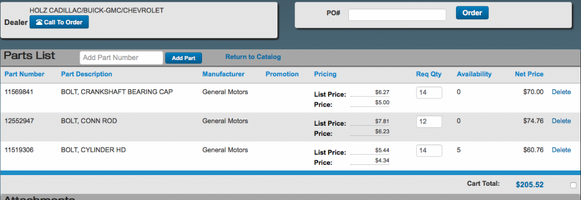

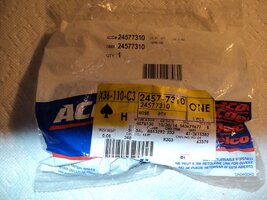

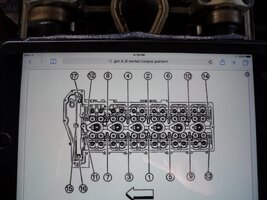

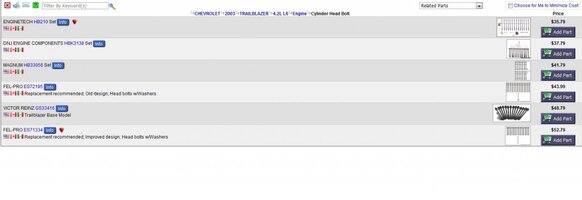

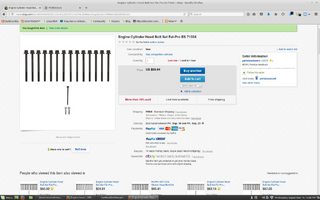

If I could... for this special case... I would very much like to discourage you from using the Modified Bolt idea... as you can clearly see in this "Side By Side" comparison between one of the Broken Bolts I extracted from my own GM Atlas 4.2L Engine vs. the ARP Bolt Hole Chasing Tool... there is simply no way a Common New Bolt will be able to get the threads cleaned up as well as they need to be to avoid having any number of the 14 Brand New Bolts subsiding or fracturings from galling and sticking inside of those deep and dirty thread-lines:

As for beginning a Brand New Thread... I agree that if this is what you'd like to do... by all means, there will no harm in doing so...with the understanding that you have already created an interested audience based upon the fact that your

"Likes Received" Numbers versus your Number of Posts are running at a ratio of greater than 1 to 1...which quite frankly, is almost an unheard of and a resounding success that seldom occurs on most forums. But... if the idea here is for you to have an uninterrupted stream of posts on a "Tabula Rasa" without any other input or guidance from others that you believe might distract or confuse what you are trying to say... Again... I will certainly respect your wishes to do it that way...and I'll leave the field that follows freely open to you as Virgin Mechanical Repair Land to navigate, cultivate and reap all of the accolades from when the time comes to Install and Start the New Rebuilt Engine for the First Time..

I just wanted to confirm with you that I have been making my postings here as the means to contribute towards a Total Stranger; whom I feel is now also my Brother in Arms for bravely attempting to do this rarely tackled Engine Rebuild. And so my comments and suggestions are meant to be benign, with the idea of trying to "yell out the presence of any "Mechanical Pot-Holes" you might encounter along the way... long before you "Break an Axle"...so to speak... Its This Damned Atlas Engine that prompts my over-abundance of Caution.

Unfortunately... we have already had another Member document a Post-Mortem of his efforts to start a recently Completely Re-built GM Atlas 4.2L LL8 Engine that ended disastrously from having seized Connecting Rod Bearings that lunched the engine... because of not having Pre-Oiled the motor before starting it for the first time. Had he been posting his work here and there along the way...we might have been able to say something or suggest something to him that would have made a profound and positive difference in the outcome.

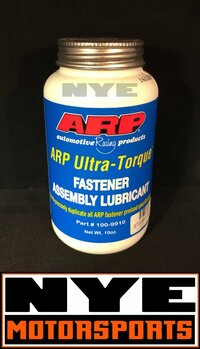

Another good example of this will happen when you watch this Part 2 of an intrepid mechanic who

places text messages on his videos to inform you that he tried to Follow the Manual and install these unusually delicate Head Bolts...WITHOUT LUBRICATION... and wound up Snapping some Off. His warning here and my own experience...and your own experience with breaking bolts... no matter how carefully the torque is applied... may prove to remain a problem in your future without the help of the ARP Special Torque Lubricant or something better than 30 Wgt Motor Oil. However...If you have had prior experiences with TTY Bolts and never suffered as others have with this re-assembly problems... I salute you:

"When The Student is Ready..... The Teacher Emerges..." Confucius