Hello fellow members! I am brand new to the forum and Chevys in general. I just sold my 1993 Lexus LS400 for something a bit bigger and just picked up a 2006 Trailblazer LS. I bought it off the second owner who had it for 10 years. Before I even looked at it, he told me he just replaced the battery. He said that the blend doors for the feet, face, and windshield were not operating correctly and were prior to replacing the battery and that it is a common issue and you need to tell the computer to relearn the actuators. Looking it up, he appears to be correct so I followed a couple recommendations to reset it and get the vents blowing right. I live in South Texas and while the A/C feels good on my feet, my upper half needs it more. I have tried pulling the fuses under the seat with the truck off and while it is on and neither have reset it. When I pull the fuses when the truck is running (HVAC B) the face vents get air, but as soon as I replace the fuse it goes back to feet or defrost. This tells me the actuator is not bad, as air will get to the face vents. Any suggestions on getting this fixed. I've got some other things I need to address with the truck to get it up to snuff, but this is my priority so I don't show up to work with cold feet and 95 degree torso!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

2006 Trailblazer A/C Vent Issue

- Thread starter richeaus

- Start date

Chickenhawk

Member

- Dec 6, 2011

- 782

I think he was correct that it is a common issue. He might have been a bit misleading when he said that all you have to do is reset the actuators. When the battery is replaced, the actuators move through their entire range of motion to find the stop points. This causes a lot of strain on the tiny plastic gears, and actuators that are 13 years old can strip those plastic gears easily. It is very common to need to replace one after a battery replacement.Before I even looked at it, he told me he just replaced the battery. He said that the blend doors for the feet, face, and windshield were not operating correctly and were prior to replacing the battery and that it is a common issue and you need to tell the computer to relearn the actuators.

Just to be sure, try the reset again. With the key out, radio off and fan off, remove that same fuse, leave it out for at least 10 seconds and replace it. Now turn the key to run (but do not start the truck) and listen to the actuators as they run through their range of motion. You will hear them very clearly. It takes about 30 seconds to 2 minutes. Be patient. Once they have all stopped moving, try it again with the fan on and go through the settings.

Most people don't wait long enough for them to find the stops before starting the truck.

Bad ones will either not move at all, or (more likely) click and buzz for a while.

Let us know.

Welcome to GMT Nation....

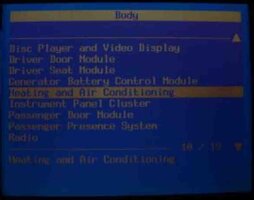

If it comes down to having to replace any HVAC Actuators… This Information can Help:

https://gmtnation.com/forums/threads/hvac-actuators-and-dash-removal.2156/

https://itstillruns.com/replace-mode-actuator-trailblazer-7975707.html

If it comes down to having to replace any HVAC Actuators… This Information can Help:

https://gmtnation.com/forums/threads/hvac-actuators-and-dash-removal.2156/

https://itstillruns.com/replace-mode-actuator-trailblazer-7975707.html

TequilaWarrior

Member

Follow @Chickenhawk 's recommendations.

For me, the only way I got it to work was to turn the HVAC completely OFF then turn off the vehicle and remove the keys, pull the correct fuses and wait (I waited like 5 minutes), reinstall the fuses. From the driver's seat, turn the vehicle to ON (but do not start it) - I immediately hit the "OFF" button on my HVAC to make sure it does not try to come on. If you have everything off (including the radio) you will likely hear the blend doors cycling to their limits. Mine takes a while, probably around 2 minutes. I believe there should be a fairly easy to hear "clicking" or ratcheting sound if they're stripped. Mine "groan" but are not stripped or broken.

For me, the only way I got it to work was to turn the HVAC completely OFF then turn off the vehicle and remove the keys, pull the correct fuses and wait (I waited like 5 minutes), reinstall the fuses. From the driver's seat, turn the vehicle to ON (but do not start it) - I immediately hit the "OFF" button on my HVAC to make sure it does not try to come on. If you have everything off (including the radio) you will likely hear the blend doors cycling to their limits. Mine takes a while, probably around 2 minutes. I believe there should be a fairly easy to hear "clicking" or ratcheting sound if they're stripped. Mine "groan" but are not stripped or broken.

Thank you all for your suggestions. I tried all of them mentioned above to no avail. Again, I know the gears are stripped because when the truck first turns on after I reset the HVAC stuff, I can hear the doors moving around and no clicking or groaning. Also, the air movement will go to the face vents for a second but then go back to the defrost and floor. I also don't have fan speeds 4 and 5, but I am certain that is due to the control module/blower motor resistor. I have that part on order. So I know that the actuator works for it, but it seems to not be listening to knob selection, but will change between feet and defrost if I move the knob or straight feet if the selection is made for just feet vents. Not sure where to keep looking at. I will be getting a day off soon so I can spend more than 15 minutes on it at a time. I think I am going to grab a schematic and locate the problem actuator to see if it is aligned to where it should be and the confirm it is moving.

TequilaWarrior

Member

I have the manual controls with the sliders. It aggravates me because I know the actuator is working, otherwise I'd suck it up and buy a new one, but I don't it is the issue. It is either the learning process or the computer that is telling it what to do. I fought with something similar on a 2012 Buick Enclave back in Automotive school and the control unit was fried but the teacher swore up and down it was the actuator until we showed him.Wait, do you have auto controls or manual controls? Does your HVAC controller have sliders?

TequilaWarrior

Member

STOP (not trying to be a douche, just trying to halt this where it is). There are definitely people here that are way more versed in this than I am. HOWEVER - I am 99% sure that myself, @Chickenhawk and @MRRSM have been operating under the assumption that you had auto controls. I do not believe that the manual controls have actuators that learn their position. I believe they are a completely different style of actuator and that there is no learning process - hence why the learning process has not worked. Something else is the problem. I don't believe the actuators for the manual controls fail easily. You may be 100% correct in thinking it's the control head. I have zero experience with the manual controls, so I'm not sure how much help I can be.

I'm pretty sure that whatever system you have the control head needs to establish the position limits for the actuators. The calibration procedure is the only way to do this. The actuators are generic - they are not specifically made for the vehicle. The mode actuator has to stop at three positions - the only way for it to calculate the middle position is to do the calibration.

The actuator failure is so common that it is one of the first things you should check after you do the calibration procedure. Remove and disassemble the actuator to see if you have cracked gears or broken teeth.

I had three go bad in my TB. Fortunately they are usually repairable and three years later all are still working fine.

The actuator failure is so common that it is one of the first things you should check after you do the calibration procedure. Remove and disassemble the actuator to see if you have cracked gears or broken teeth.

I had three go bad in my TB. Fortunately they are usually repairable and three years later all are still working fine.

TequilaWarrior

Member

THat doesn't sound right. There are different part numbers for the actuators for a manual system vs auto. Auto systems run in a closed loop and include sensors in the ducts to provide feedback about output temperatures. THe control head would then use that data to command the actuators to move just enough to achieve the desired temperature - receiving feedback about commanded position vs current position and adjusting accordingly.

I thought the manual controls simply opened/closed a given percentage - there is no closed loop. I didn't think their actuators needed to do a learning procedure as they don't provide feedback about commanded position vs current position.

I thought the manual controls simply opened/closed a given percentage - there is no closed loop. I didn't think their actuators needed to do a learning procedure as they don't provide feedback about commanded position vs current position.

TequilaWarrior

Member

Now I'm questioning my understanding of how the manual vs auto ac works as I can't find any posts specifically stating what I thought I read.... dang it.

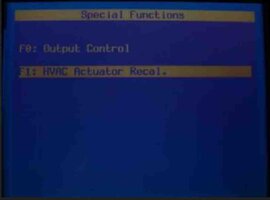

Easy enough for you to check. Do the recalibrate procedure and listen carefully for the actuators moving, if you hear that then it works the same way in both auto and manual systems.

If you look at the connector on the actuator and see five pins - it has a position sensor. There are some actuators that just travel from from one position to another, but I don't think the TB uses them.

If you look at the connector on the actuator and see five pins - it has a position sensor. There are some actuators that just travel from from one position to another, but I don't think the TB uses them.

Hobbyist4Life

Member

THat doesn't sound right. There are different part numbers for the actuators for a manual system vs auto. Auto systems run in a closed loop and include sensors in the ducts to provide feedback about output temperatures. THe control head would then use that data to command the actuators to move just enough to achieve the desired temperature - receiving feedback about commanded position vs current position and adjusting accordingly.

I thought the manual controls simply opened/closed a given percentage - there is no closed loop. I didn't think their actuators needed to do a learning procedure as they don't provide feedback about commanded position vs current position.

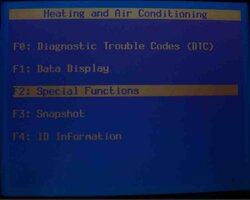

My 05 TB LS has manual controls and I can confirm from personal experience that the relearn process is the same, and they still provide commanded vs current position on a Tech2/advanced scanners.