- Jan 28, 2014

- 90

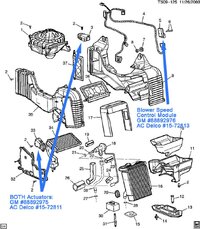

My 03 Envoy XL rear air flow actuator decided to start failing. I picked up a new Delco 1572811 actuator and started the install, not as bad as I was thinking it would be. I removed the old actuator and went to install the new actuator and the alignment is off to much to get it indexed on the shaft. How does one move the gear in the actuator to align ? The shaft does not move very much from floor to vents but there is no binding and it functions properly when the truck is running and moved manually. I was thinking there must be a way to apply power to the proper pins to move the gear to align. Looking for advise.