Inferno333

Member

- Joined

- Oct 9, 2014

- Posts

- 131

And... Code light back on...

Gonna read it tonight, but I'm assuming it's the same misfire back again.

Gonna read it tonight, but I'm assuming it's the same misfire back again.

Could be a weak of failing valve spring or damper, making it bounce at speed. Definitely also check for a leak at the intake manifold.

I had a Dodge V8 that had an intermittent misfire on one cylinder. I did all the things, swap coils, plugs, injectors, checked compression, etc. At times it would go for days with no misfire. Finally, I found out that the oil pressure would intermittently drop low, lots of oiling problems with these engines. When the oil pressure dropped the lifter failed to open the exhaust valve on this one cylinder. Dodge had revised lifters to address this, not the oiling problem! It did fix the misfire.

It could very well be a bad/weak lifter.

AC Delco, or Denso (I believe Denso makes the AC Delco sensors).

I did fine with a Bosch in mine, but historically Bosch sensors and GM haven't gotten along.

Downstream simply checks for proper cat function and won't affect engine performance. I wouldn't bother with it. And the only upstream sensor I'd bother with would be on the side that is giving you trouble (#7 is driver side closest to the firewall I believe).

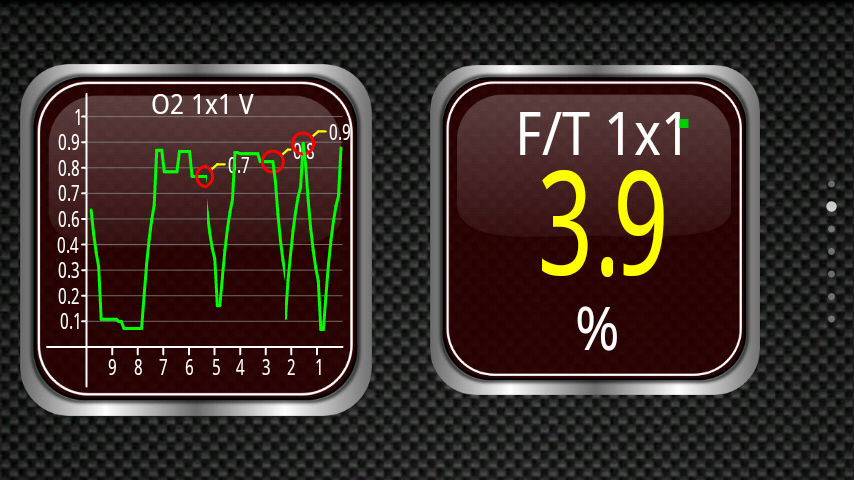

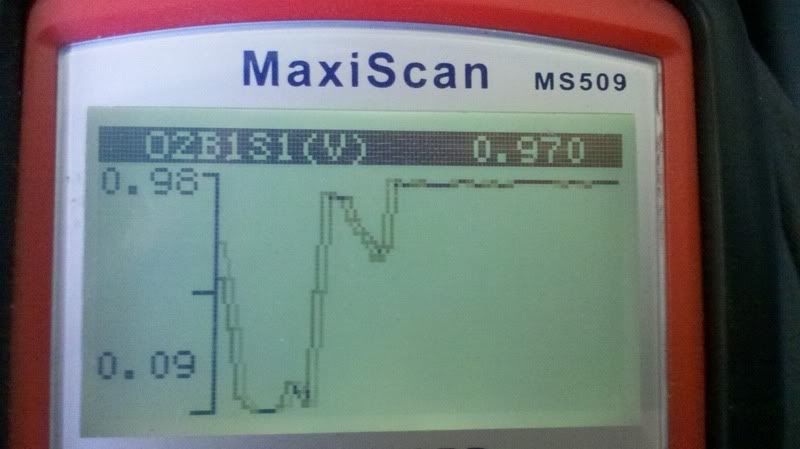

Your best bet is to find an an Android device and get Torque or Torque Pro.

He did a compression test and it came back ~135psi. He pulled the valve cover and didn't find anything wrong along with swapping injectors and blowing out the fuel rail.

A normal reading should be approximately 1482 kPa (215 psi).

The lowest reading should not be less than 70 percent of the highest reading.

The minimum compression in any 1 cylinder should not be less than 70 percent of the highest cylinder. No cylinder should read less than 690 kPa (100 psi). For example, if the highest pressure in any 1 cylinder is 1 035 kPa (150 psi), the lowest allowable pressure for any other cylinder would be 725 kPa (105 psi). (1 035 x 70% = 725) (150 x 70% = 105).

OK, here's the compression specs for the 5.3:

So at 135 psi, sounds right.