To begin this HP Tuners Thread… The FIRST Place I went directly to was THIS Site:

www.hptuners.com

www.hptuners.com

… and Signed Up as a New Member on Friday, June 28th, 2019, Filled in My Basic Profile as “MRRSM” and after Navigating to the Main Page...Sought out and Downloaded ALL of the Introductory FAQs and Main Links to Common Q&A Issues for Beginners in order to Save Time and Help Myself to a Wide Array of EXCELLENT Information, Documents and Links to Videos:

www.hptuners.com

www.hptuners.com

Next Up… This GMT Nation HP Tuners Thread will be a Branch-Off from the Original “Hoping for Loping” Thread and will cover the PCM-ECM Clone, Swap (1 for 1) and HPT “Tuning” of the 2000 Chevrolet Silverado 1500 5.3L Long Bed Truck.

Major PCM-ECM Programmer and Controller Hardware/Software Involved:

(1) A Bosch Vetronix “GYMKO” Tech 2 Full Scanner Kit.

(2) A Dedicated Dell M65 Laptop with the Windows XP Professional Ver. SP3 along with TIS2000 and a USB “HWK” (Hard Ware Key) aka ‘Dongle’ Security Validation Key.

(3) A HP Tuners MVPI 1 Programmer, Cabling, Datalogger and Installation Software Kit.

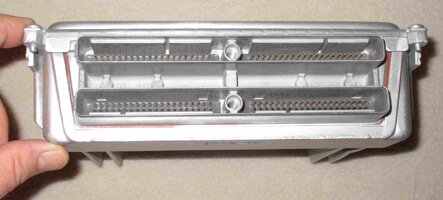

(4) A GM LS ‘Bench Top” Power and Communication “Blue” Harness (arrived Friday, June 28, 2019)

(5) An AC/DC Adjustable Power Supply.

(6) An ES5000 “Booster PAC” 1500 AMP Battery Power Supply to Power the Tech 2 & PCM through the DLC during SPS and Tech 2 use inside of the Y2K Truck.

(7) Two GM PCM-ECUs Circa 1999-2006 (One for “Bench Top” Tuning; One for the Y2K Truck.

(8) UPS-750 Uninterrupted Power Supply to Guarantee Steady Power to BOTH AC/DC Power Converters due to frequent Power Fluctuations from Thunderstorm Outages down here in Florida.

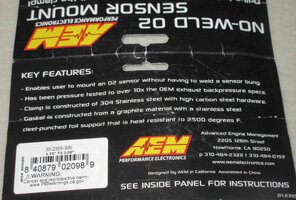

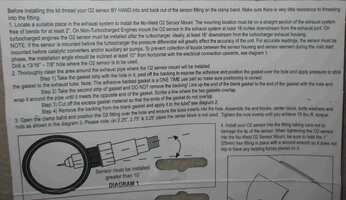

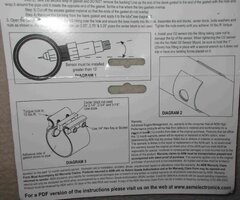

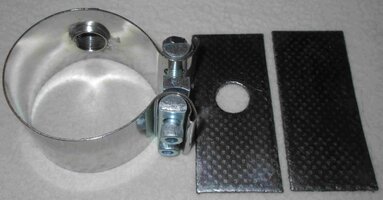

(9) Wide Band O2 Analog Sensor and Wiring (The HP Tuners MVPI-1 is equipped to Accept, Read and Store this “Fine Grain” Stoichiometric Data).

Engine Type and Internal/External Component Considerations for HPT Tuning:

(1) GM 5.3L LM-7 V8

(2) Stock Throttle Body- using Non-Electronic Cable Control

(3) DNA Stainless Steel “Shorty” Exhaust Headers

(4) Stock Dual Catalytic Converters

(5) Full 3” CAT-back Exhaust

(6) Texas Speed and Performance Low Lift Stage 2 Model # 25-LL212218112 .550”/.550” Camshaft

(7) Locating and Welding in a New Wide Band O2 Sensor Bung close to the "Y" Pipe Collector

Naturally… it is “Early in The Game” of trying to figure out the best ways to work with HP Tuners between “paired” PCM-ECMS when having one mounted inside the Y2K Truck...while the other serves as the “Tuner Platform” to Create and Manipulate all of the variations with the HPT Tunes and get the Truck to Start, Idle, Accelerate, Shift and Decelerate while trying to keep “Stoich” as close to 14.7:1 as possible and avoid running Too Lean and either Stalling out and hurting either Engine or the 4L60E Transmission along the way. And so here is where I have many questions which will need answering by searching on the HP Tuners Site First ...before I set up all of this Gear and finally get to work on things:

(Q1) Is it possible to “Clone” a GM PCM-ECU with an Identical Vehicle Identification Number and Factory Calibration that match IN EVERY RESPECT?

(A1) In a Word: Yes. The GM TIS2000 SPS Program has a feature during the PASS-THRU to Program a Replacement PCM and will pause to allow the Tech 2 SPS Programmer to Key in the Identical VIN and then load the latest Calibration(s) onto the PCM-ECM.

(Q2) Will Cloning the PCM cause problems with the Y2K Truck BCM?

(A2) No… As long as there is a proper amount of Stable Voltage DC to keep the “GYMKO” Tech 2 AND The PCM powered throughout the SPS PASS-THRU Calibration procedures, there should not be a problem. In particular… the Early GM OBD2 Based PCM-ECMS are interchangeable without being disruptive to other Body Control parameters such as with the Air Bags.

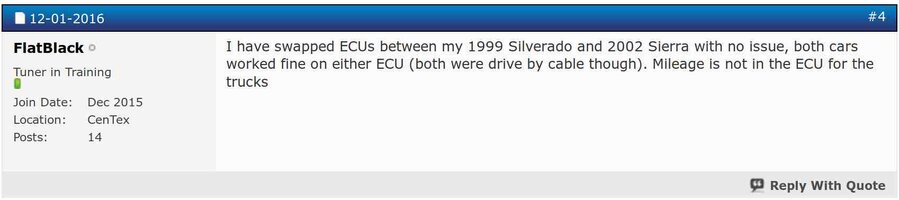

(Q3) Will Cloning a New PCM cause problems with the accuracy of the Odometer?

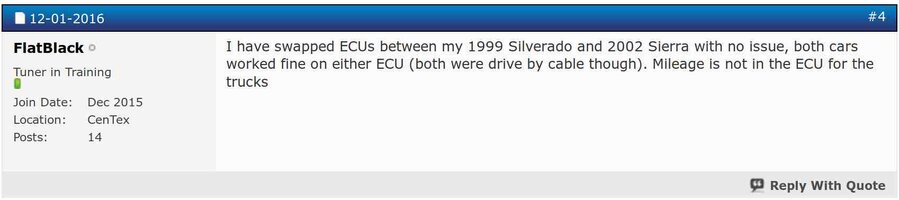

(A3) No. The Odometer readings are maintained within the Truck BCM. (See Anecdotal Image of an HP Tuners Thread Posting...)

(Q4) HP Tuners has Very Steep Learning Curve… What Training Resources are available?

(A4) HP Tuners has a very popular HPT Forum where Owners-Users and even Professional Tuners have many Threads and Member Resources on related topics to assist with Learning. Youtube also offers a great many very well documented Training Videos; some which are surprisingly quite particular and very close to the issues and parameters I’ll have to overcome with my Y2K Truck.

Those particular Videos will help me to Navigate and become Familiar with How Best to Use the HP Tuners Hardware, Software, “Hands on Tuning” and the Datalogging necessary for the Trial and Error Datalogs. These actions will be indispensable for knowing where to make corrections and improvements of a variety of Tunes that will change the LM7 from being a “Stock as a Clock” Motor over to a Better Running, Jumping, Leaping and … “Hopefully Loping” Performance Engine. :>)

I will post the YT Links to the Most relevant Videos in due time. One very important GMT Nation Member has come forward and offered Aid and Assistance regarding How to Use HP Tuners. In More Ways than One... He is @2advanced … and I’m very grateful for his generous assistance with some additional Tunes that I can begin experimenting with very soon. Earlier this afternoon… The Professional Quality LS PCM OBD2 Power Harness via eBay arrived... with a few images attached below for display:

More to Follow as the Rest of the HP Tuners Hardware & Software arrives...

HP Tuners – Home

HP Tuners is the leading automotive diagnostic and calibration solution with factory ECU and standalone engine management products.

… and Signed Up as a New Member on Friday, June 28th, 2019, Filled in My Basic Profile as “MRRSM” and after Navigating to the Main Page...Sought out and Downloaded ALL of the Introductory FAQs and Main Links to Common Q&A Issues for Beginners in order to Save Time and Help Myself to a Wide Array of EXCELLENT Information, Documents and Links to Videos:

HP Tuners – Home

HP Tuners is the leading automotive diagnostic and calibration solution with factory ECU and standalone engine management products.

Next Up… This GMT Nation HP Tuners Thread will be a Branch-Off from the Original “Hoping for Loping” Thread and will cover the PCM-ECM Clone, Swap (1 for 1) and HPT “Tuning” of the 2000 Chevrolet Silverado 1500 5.3L Long Bed Truck.

Major PCM-ECM Programmer and Controller Hardware/Software Involved:

(1) A Bosch Vetronix “GYMKO” Tech 2 Full Scanner Kit.

(2) A Dedicated Dell M65 Laptop with the Windows XP Professional Ver. SP3 along with TIS2000 and a USB “HWK” (Hard Ware Key) aka ‘Dongle’ Security Validation Key.

(3) A HP Tuners MVPI 1 Programmer, Cabling, Datalogger and Installation Software Kit.

(4) A GM LS ‘Bench Top” Power and Communication “Blue” Harness (arrived Friday, June 28, 2019)

(5) An AC/DC Adjustable Power Supply.

(6) An ES5000 “Booster PAC” 1500 AMP Battery Power Supply to Power the Tech 2 & PCM through the DLC during SPS and Tech 2 use inside of the Y2K Truck.

(7) Two GM PCM-ECUs Circa 1999-2006 (One for “Bench Top” Tuning; One for the Y2K Truck.

(8) UPS-750 Uninterrupted Power Supply to Guarantee Steady Power to BOTH AC/DC Power Converters due to frequent Power Fluctuations from Thunderstorm Outages down here in Florida.

(9) Wide Band O2 Analog Sensor and Wiring (The HP Tuners MVPI-1 is equipped to Accept, Read and Store this “Fine Grain” Stoichiometric Data).

Engine Type and Internal/External Component Considerations for HPT Tuning:

(1) GM 5.3L LM-7 V8

(2) Stock Throttle Body- using Non-Electronic Cable Control

(3) DNA Stainless Steel “Shorty” Exhaust Headers

(4) Stock Dual Catalytic Converters

(5) Full 3” CAT-back Exhaust

(6) Texas Speed and Performance Low Lift Stage 2 Model # 25-LL212218112 .550”/.550” Camshaft

(7) Locating and Welding in a New Wide Band O2 Sensor Bung close to the "Y" Pipe Collector

Naturally… it is “Early in The Game” of trying to figure out the best ways to work with HP Tuners between “paired” PCM-ECMS when having one mounted inside the Y2K Truck...while the other serves as the “Tuner Platform” to Create and Manipulate all of the variations with the HPT Tunes and get the Truck to Start, Idle, Accelerate, Shift and Decelerate while trying to keep “Stoich” as close to 14.7:1 as possible and avoid running Too Lean and either Stalling out and hurting either Engine or the 4L60E Transmission along the way. And so here is where I have many questions which will need answering by searching on the HP Tuners Site First ...before I set up all of this Gear and finally get to work on things:

(Q1) Is it possible to “Clone” a GM PCM-ECU with an Identical Vehicle Identification Number and Factory Calibration that match IN EVERY RESPECT?

(A1) In a Word: Yes. The GM TIS2000 SPS Program has a feature during the PASS-THRU to Program a Replacement PCM and will pause to allow the Tech 2 SPS Programmer to Key in the Identical VIN and then load the latest Calibration(s) onto the PCM-ECM.

(Q2) Will Cloning the PCM cause problems with the Y2K Truck BCM?

(A2) No… As long as there is a proper amount of Stable Voltage DC to keep the “GYMKO” Tech 2 AND The PCM powered throughout the SPS PASS-THRU Calibration procedures, there should not be a problem. In particular… the Early GM OBD2 Based PCM-ECMS are interchangeable without being disruptive to other Body Control parameters such as with the Air Bags.

(Q3) Will Cloning a New PCM cause problems with the accuracy of the Odometer?

(A3) No. The Odometer readings are maintained within the Truck BCM. (See Anecdotal Image of an HP Tuners Thread Posting...)

(Q4) HP Tuners has Very Steep Learning Curve… What Training Resources are available?

(A4) HP Tuners has a very popular HPT Forum where Owners-Users and even Professional Tuners have many Threads and Member Resources on related topics to assist with Learning. Youtube also offers a great many very well documented Training Videos; some which are surprisingly quite particular and very close to the issues and parameters I’ll have to overcome with my Y2K Truck.

Those particular Videos will help me to Navigate and become Familiar with How Best to Use the HP Tuners Hardware, Software, “Hands on Tuning” and the Datalogging necessary for the Trial and Error Datalogs. These actions will be indispensable for knowing where to make corrections and improvements of a variety of Tunes that will change the LM7 from being a “Stock as a Clock” Motor over to a Better Running, Jumping, Leaping and … “Hopefully Loping” Performance Engine. :>)

I will post the YT Links to the Most relevant Videos in due time. One very important GMT Nation Member has come forward and offered Aid and Assistance regarding How to Use HP Tuners. In More Ways than One... He is @2advanced … and I’m very grateful for his generous assistance with some additional Tunes that I can begin experimenting with very soon. Earlier this afternoon… The Professional Quality LS PCM OBD2 Power Harness via eBay arrived... with a few images attached below for display:

More to Follow as the Rest of the HP Tuners Hardware & Software arrives...

Last edited: