Good Afternoon,

I am wanting to level/lift out my tb, not only do I not like the rake but I also do some mild off roading while hunting and such. I have been researching lifts and while liftmiester lifts look great, I am cheap and I like knowing I have steel supporting my suspension. So I am thinking about building my own lift. I teach shop at school so I have the equipment and the know how when it comes to welding it up. I have been researching lifts. There are some lifts that mount above the strut assembly and some that mount above the springs and below the strut mount. I have read that there are problems with the lifts above the whole assembly.

I am wanting to put roughly a 2" lift on and want to know if it would cause problems to build a lift that goes above the strut assembly? If so why would it be a problem?

Just so you know I am looking at useing 3/8" plate and 1/4" wall pipe to build the spacers in the front, and use solid round stock for the rear spacers.

I am wanting to level/lift out my tb, not only do I not like the rake but I also do some mild off roading while hunting and such. I have been researching lifts and while liftmiester lifts look great, I am cheap and I like knowing I have steel supporting my suspension. So I am thinking about building my own lift. I teach shop at school so I have the equipment and the know how when it comes to welding it up. I have been researching lifts. There are some lifts that mount above the strut assembly and some that mount above the springs and below the strut mount. I have read that there are problems with the lifts above the whole assembly.

I am wanting to put roughly a 2" lift on and want to know if it would cause problems to build a lift that goes above the strut assembly? If so why would it be a problem?

Just so you know I am looking at useing 3/8" plate and 1/4" wall pipe to build the spacers in the front, and use solid round stock for the rear spacers.

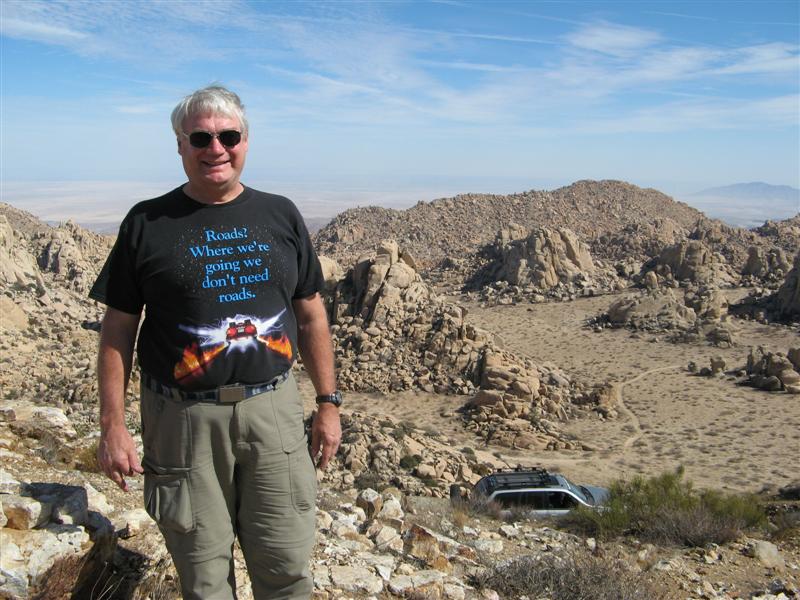

I have been places I never would have gone without the lift, worth every penny and the increased size of my carbon footprint which makes hippies cry.

I have been places I never would have gone without the lift, worth every penny and the increased size of my carbon footprint which makes hippies cry.

I have two of them, and I've never once rolled down a 4000 foot dropoff while wearing one.

I have two of them, and I've never once rolled down a 4000 foot dropoff while wearing one.