As others have mentioned, I don't think the pry bar will help

Yours sound like it might be corroded so you have to break the corrosion through impact first.

Have you tried a pickle fork right where the axle goes into the oil pan / disconnect housing? I imagine the tapered fork with a solid hit with a hammer will be enough to force it loose?

When i did mine, I removed the spindle so the CV shaft wasn't connected to the bearing at all. I wasn't sure if there would be enough 'play' for the CV axle to pop out of the disconnect if it was still connected to the wheel bearing. A lot of of people recommend leaving it connected and just undo the top ball joint, but I disconnected everything.

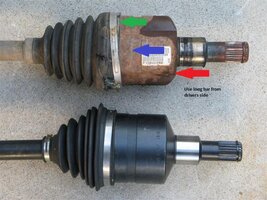

1 more suggestion .. if you're using the drift bar method, try and keep the bar as horizontal as possible. You want all the energy from the hammer/mallet to be transferred to push the CV axle outward, not upward.

Yours sound like it might be corroded so you have to break the corrosion through impact first.

Yours sound like it might be corroded so you have to break the corrosion through impact first.