- Aug 26, 2012

- 1,079

had a brain fart earlier today i want to run past you.

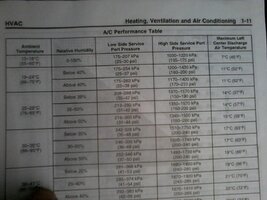

last spring I replaced the thermostat, old one was too cold. temp seems ok, but with the new thermostat, the AC got flaky, when very hot (at first when 100 and in traffic, by the end of the summer, would happen on an uphill run to work in the high 90s, with humidity)

a few threads here discuss some thermostats which do not open well. i was thinking if the coolant flow was restricted, it could get too hot, and the computer would turn off the AC compressor to save the motor. a couple times I noticed the temp gauge inching up a bit as the AC cut out

( I guess I am a little fuzzy on how hot that would have to be)

i now have some software which should be able to catch the details. so when it does finally get hot, might be able to figure out exactly what is up, and if it seems connected, or just a few old AC clutch coils.

do you think if the thermostat is not opening up all the way it would cause the AC to cut out?

last spring I replaced the thermostat, old one was too cold. temp seems ok, but with the new thermostat, the AC got flaky, when very hot (at first when 100 and in traffic, by the end of the summer, would happen on an uphill run to work in the high 90s, with humidity)

a few threads here discuss some thermostats which do not open well. i was thinking if the coolant flow was restricted, it could get too hot, and the computer would turn off the AC compressor to save the motor. a couple times I noticed the temp gauge inching up a bit as the AC cut out

( I guess I am a little fuzzy on how hot that would have to be)

i now have some software which should be able to catch the details. so when it does finally get hot, might be able to figure out exactly what is up, and if it seems connected, or just a few old AC clutch coils.

do you think if the thermostat is not opening up all the way it would cause the AC to cut out?