Confused on AC rebuild w/ compressor plug an switch?

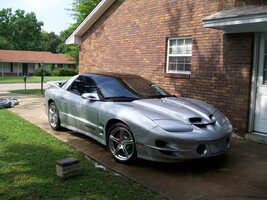

Hello all: after a bunch of studying an video watching I’m attempting to rebuild the complete AC sys. On my 4th gen.99pontica tran am

I purchased the GPD complete kit minus the evaporator core.they have zero customer support.they do have a few brief videos but neglected to mention this plu an switch.

What I’m confused on according to there instructions is removing a plug inside the compressor an installing a switch on compressor.they neglected to include the instruction sheet for switch install but do make it appear this compressor needs a switch and there special tool to remove switch from old comp. an install to new comp.

Not sure what this switch even is my old comp. doesn’t have it unless it’s inside the comp. case.

Maybe GPD is confusing there switch w/ a high pressure sensor which is located on the high pressure metal tube out of the condenser then into the firewall which is input to evap.core, the other sensor is on the low pressure metal line.

Not sure about the plug, there’s a c-clip holding a cover w/ a nipple to pry up to remove

Like is there a blockoff of some kind that needs removing? Then replace the cover an c-clip?

Attached GPD instructions/new an old compressor.

next I’ll ask about the type /amount/where to pour the oil. Thanks for much needed advice

Hello all: after a bunch of studying an video watching I’m attempting to rebuild the complete AC sys. On my 4th gen.99pontica tran am

I purchased the GPD complete kit minus the evaporator core.they have zero customer support.they do have a few brief videos but neglected to mention this plu an switch.

What I’m confused on according to there instructions is removing a plug inside the compressor an installing a switch on compressor.they neglected to include the instruction sheet for switch install but do make it appear this compressor needs a switch and there special tool to remove switch from old comp. an install to new comp.

Not sure what this switch even is my old comp. doesn’t have it unless it’s inside the comp. case.

Maybe GPD is confusing there switch w/ a high pressure sensor which is located on the high pressure metal tube out of the condenser then into the firewall which is input to evap.core, the other sensor is on the low pressure metal line.

Not sure about the plug, there’s a c-clip holding a cover w/ a nipple to pry up to remove

Like is there a blockoff of some kind that needs removing? Then replace the cover an c-clip?

Attached GPD instructions/new an old compressor.

next I’ll ask about the type /amount/where to pour the oil. Thanks for much needed advice