It's not that difficult to do yourself with a little DIY knowhow. You need to replace the drier and pull a full vacuum to do this correctly. The vacuum is essential to pull the air out that you let in. Also it's important is to pull out the moisture. Anything beside r134a and oil in your system will kill the compressor faster and make it cool less efficiently.

Makes me laugh when I hear people at the local auto parts store just topping off their AC system with a new can of air. AC systems are not designed to ever leak. If you have to "top it off for the summer" then obviously you have a leak. The system will cool progressively less and less and overwork the compressor. Also, the oil will turn acidic when exposed to air and again rapidly destroy the compressor

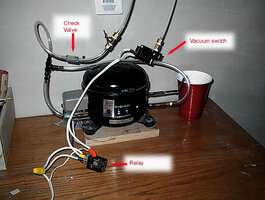

I purchased the gauges and made my own vacuum pump with an old deep freeze compressor. Brazed on my own fittings. Here in TX there is no chance I'd go without AC.

I know this is probably way more info than you need, but just in case any of you go the DIY route

COMPRESSOR

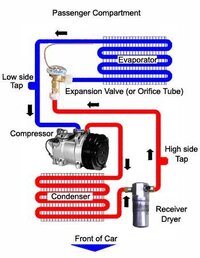

The compressor is responsible for compressing and transferring refrigerant gas. The A/C system is split into two sides, a high pressure side and a low pressure side; defined as discharge and suction. Since the compressor is basically a pump, it must have an intake side and a discharge side. The intake, or suction side, draws in refrigerant gas from the outlet of the evaporator. Once the refrigerant is drawn into the suction side, it is compressed and sent to the condenser, where it can then transfer the heat that is absorbed from the inside of the vehicle.

CONDENSER

The condenser is the area in which heat dissipation occurs. The condenser will have much the same appearance as the radiator in your car as the two have very similar functions. The condenser is designed to radiate heat. Condensers must have good air flow anytime the system is in operation. On our Legends, the condenser air flow is supplemented by the electric cooling fan(s). As hot compressed gasses are introduced into the top of the condenser, they are cooled off. As the gas cools, it condenses and exits the bottom of the condenser as a high pressure liquid.

RECEIVER-DRIER

The receiver-drier is used on the high side of systems that use a thermal expansion valve, as in our Legends. This type of metering valve requires liquid refrigerant. To ensure that the valve gets liquid refrigerant, a receiver is used. The primary function of the receiver-drier is to separate gas and liquid. The secondary purpose is to remove moisture and filter out contaminants. The receiver-drier has the sight glass in the top. This sight glass is often used to charge the system. Under normal operating conditions, vapor bubbles should not be visible in the sight glass. The use of the sight glass to charge the system is not recommended in R-134a systems as cloudiness and oil that has separated from the refrigerant can be mistaken for bubbles. This type of mistake can lead to a dangerous overcharged condition. There are variations of receiver-driers and several different desiccant materials are in use. Some of the moisture removing desiccants found within are not compatible with R-134a. The desiccant type is usually identified on a sticker that is affixed to the receiver-drier. Newer receiver-driers use desiccant type XH-7 and are compatible with both R-12 and R-134a refrigerants.

PRESSURE REGULATING DEVICE

Controlling the evaporator temperature is accomplished by controlling refrigerant pressure and flow into the evaporator.

THERMAL EXPANSION VALVE

The refrigerant regulator used in our Legends is the thermal expansion valve, or TXV. Commonly used on import and aftermarket systems. This type of valve can sense both temperature and pressure, and is very efficient at regulating refrigerant flow to the evaporator. This type of valve, although efficient, has some disadvantages over orifice tube systems. Like orifice tubes these valves can become clogged with debris, but also have small moving parts that may stick and malfunction due to corrosion.

EVAPORATOR

Located inside the vehicle, the evaporator serves as the heat absorption component. The evaporator provides several functions. Its primary duty is to remove heat from the inside of your vehicle. A secondary benefit is dehumidification. As warmer air travels through the aluminum fins of the cooler evaporator coil, the moisture contained in the air condenses on its surface. Dust and pollen passing through stick to its wet surfaces and drain off to the outside. On humid days you may have seen this as water dripping from the bottom of your vehicle. Rest assured this is perfectly normal. The ideal temperature of the evaporator is 32° Fahrenheit or 0° Celsius. Refrigerant enters the bottom of the evaporator as a low pressure liquid. The warm air passing through the evaporator fins causes the refrigerant to boil (refrigerants have very low boiling points). As the refrigerant begins to boil, it can absorb large amounts of heat. This heat is then carried off with the refrigerant to the outside of the vehicle. Several other components work in conjunction with the evaporator. As mentioned above, the ideal temperature for an evaporator coil is 32° F. Temperature and pressure regulating devices must be used to control its temperature. The pressure regulating device, in our case the TXV, functions to keep pressure in the evaporator low and keep the evaporator from freezing; A frozen evaporator coil will not absorb as much heat.

more GMT360 curiosities

more GMT360 curiosities

uh oh, its the nitpick police! hands up!

uh oh, its the nitpick police! hands up!

I even thought about it as I was typing it. And used the longer and correct word later. Just failed to go back and replace "freon" later.

I even thought about it as I was typing it. And used the longer and correct word later. Just failed to go back and replace "freon" later.