The good news is, you don't have to remove it from the channel, you'll reuse it to seal them back together again. You just need to get it off the visible surfaces, that's all.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Another HID Thread! This Time with LT Lenses.

- Thread starter l008com

- Start date

l008com

Member

But won't the stuff in the channel prevent me from inserting the clear part in to that very channel?

Sparky

Member

- Joined

- Dec 4, 2011

- Posts

- 12,927

What I did was just do my best with it cold using a flat blade screwdriver to dig it out of the channel and a blade to cut it off the lens, then I used RTV to glue them back together. Maybe not the best idea as I could not reopen to fix an alignment issue...

When I resealed mine, I put them face down on a piece of cardboard. Let the weight of the assembly plus the projectors pull them together. As the rubber softened from the heat, it self seals. Gave them one last press when I pulled them out, but the front lens didn't move.

I did have a couple of small spots that didn't have enough, and allowed some moisture in, so I used a smear of RTV on the edge of the lens and housing, and that solved that.

I did have a couple of small spots that didn't have enough, and allowed some moisture in, so I used a smear of RTV on the edge of the lens and housing, and that solved that.

l008com

Member

Another 4 hours, another half a lens clean. I'm getting there, very slowly but surely. I'm going to have to take a break for a bit though, that stuff is so sticky it is brutal on the skin on your fingers.

l008com

Member

So I got all the glue off the transparent lenses months ago. Then I got busy. I'm just getting back to this now.

I'm trying to get the glue off of the main body of the lights. Which means up out of the slot that goes all the way around. I'm very open to any suggestions anyone has about how to do this. Spinning a small screw driver around in there gets some out but it spreads it around more than it removes. I've been looking at these lights on my floor for way too long, time to get this project finished and off my plate (and also time to be able to see the road at night)

I'm trying to get the glue off of the main body of the lights. Which means up out of the slot that goes all the way around. I'm very open to any suggestions anyone has about how to do this. Spinning a small screw driver around in there gets some out but it spreads it around more than it removes. I've been looking at these lights on my floor for way too long, time to get this project finished and off my plate (and also time to be able to see the road at night)

You don't need to clean out the channel on the main housing. You're just going to put it back in there to seal it up when you're done. As long as you get it off any visible surfaces that would be seen after completion (the bezel, reflector bowls, or main lens, then you're good to go.

l008com

Member

You don't need to clean out the channel on the main housing. You're just going to put it back in there to seal it up when you're done. As long as you get it off any visible surfaces that would be seen after completion (the bezel, reflector bowls, or main lens, then you're good to go.

BUT but but how will I get the lens down in the channel if theres glue on both sides of it. Doesn't seem like it will really go in?

BUT but but how will I get the lens down in the channel if theres glue on both sides of it. Doesn't seem like it will really go in?

See our exchange about this from a couple months ago

But won't the stuff in the channel prevent me from inserting the clear part in to that very channel?

When I resealed mine, I put them face down on a piece of cardboard. Let the weight of the assembly plus the projectors pull them together. As the rubber softened from the heat, it self seals. Gave them one last press when I pulled them out, but the front lens didn't move.

l008com

Member

This project has been going on for a longgggg time

In your old message above, you are talking about baking them closed?

As it turns out, I was able to eventually come up with a method to fully clean out the channels using a small philips head, a lot of twisting, and extremely slow progress. I'm going to fully clean them out just to make my life easier. Then I'll be back to try to figure out the wiring situation.

In your old message above, you are talking about baking them closed?

As it turns out, I was able to eventually come up with a method to fully clean out the channels using a small philips head, a lot of twisting, and extremely slow progress. I'm going to fully clean them out just to make my life easier. Then I'll be back to try to figure out the wiring situation.

Yes, if you plan to use butyl rubber to seal them back up, you'll have to bake them again. Same concept, the heat softens it so it's like chewing gum, and the weight of the housing pulls down onto the lens, the rubber fills in the gaps as it evens out.

If you're going to use some other method to seal them shut, then that's a whole other story, and yes, you'd need to clean the channel out. Like Sparky did, because he was using RTV, not butyl, to close his.

If you're going to use some other method to seal them shut, then that's a whole other story, and yes, you'd need to clean the channel out. Like Sparky did, because he was using RTV, not butyl, to close his.

l008com

Member

Hmm might be easier to use something like 3M 5200 adhesive. Although that might make it too permanent if I ever need to get back inside for some reason.

l008com

Member

Finally finished getting all the butyl off the lenses. That was not fun. Next up is the DRL killing relay mod. If I can pull that off, then it will be time to order the actual projectors and see what wiring I need to do inside the headlights themselves.

Depending on what kinda projectors you get, the only wiring mod you might need is on the high beam circuit. Right now, I'm only running the high beam from the projector, high beam bucket is empty, so all I needed to do was add a male 9006 socket to the pins of the high beam solenoid of the projector. (super easy to do, since mine already had the pins crimped on)

Another option is to do is a high beam splitter, (which are available pretty cheap) so you can use the projector high beam (if it's bi-xenon) as well as the stock high beam for quads.

Of course, if you go with low beam only projectors, then no wiring mods are needed at all.

Another option is to do is a high beam splitter, (which are available pretty cheap) so you can use the projector high beam (if it's bi-xenon) as well as the stock high beam for quads.

Of course, if you go with low beam only projectors, then no wiring mods are needed at all.

l008com

Member

I was planning on going with bi-xenon, I thought they were still going to be pretty much plug and play? Except I'd want to wire up the projector into the internal wiring of the headlight anyway so I could use the power connector already on the outside of the headlight lens. That way its a direct switch if I ever have a problem and need to switch back.

Is this what you had to do? Reading your description, I'm a little unclear on what you are saying you had to do.

I have some LED DRL's I'm going to put in the high beam bay, those of course will be wired up completely custom.

Is this what you had to do? Reading your description, I'm a little unclear on what you are saying you had to do.

I have some LED DRL's I'm going to put in the high beam bay, those of course will be wired up completely custom.

I couldn't find my 9006 test lead, so using a splitter to illustrate.  All of my connections are inside the headlight, so it's clean, and plug and play. Sounds like the same thing you're looking to do.

All of my connections are inside the headlight, so it's clean, and plug and play. Sounds like the same thing you're looking to do.

You've got your 2 wires for the high beam solenoid coming off the projector, depending on where you get yours, they may already have the male pins crimped to them. This old D2S projector, I bought used off a forum member, so they were just cut off. So all you'd have to do is insert them into a 9006 male socket (after confirming your polarity with the female socket since there's a notch for the retaining clip)

Pretend that splitter is the plug for the high beam bulb, it would then plug into the projector connection ( I tucked these behind the reflector bowl, in the center section between the 2 openings in the back of the headlight assembly) Hope that makes things a little clearer.

All of my connections are inside the headlight, so it's clean, and plug and play. Sounds like the same thing you're looking to do.

All of my connections are inside the headlight, so it's clean, and plug and play. Sounds like the same thing you're looking to do.You've got your 2 wires for the high beam solenoid coming off the projector, depending on where you get yours, they may already have the male pins crimped to them. This old D2S projector, I bought used off a forum member, so they were just cut off. So all you'd have to do is insert them into a 9006 male socket (after confirming your polarity with the female socket since there's a notch for the retaining clip)

Pretend that splitter is the plug for the high beam bulb, it would then plug into the projector connection ( I tucked these behind the reflector bowl, in the center section between the 2 openings in the back of the headlight assembly) Hope that makes things a little clearer.

l008com

Member

So did you cut the splitter and hard wire that into the wires inside the lens? Also where is the ballast in your setup?

The splitter is just a substitute in this illustration. I took the high beam plug that's already in the headlight, and plugged it into the socket I connected to the projector. It can easily be disconnected if there was a reason to.

The ballasts are in the engine bay, behind the headlights. They are way too big to be placed anywhere inside our assemblies. Plus, your bulbs are going to protrude out the back.

H1 bulbs have wires coming out, this connection is called AMP, your universal ballasts will have this same polarized dual connection. Often times they will come with a rubber grommet, and a 9006 plug as well. This is so you can feed the low beam bulb connection to it, which passes to the input of the HID ballast to activate it when your OEM low beams come on. Then the output of the HID ballast goes into the AMP connections of the HID bulb, to activate them.

D2 series bulbs don't have wires connected to them, but they still stick out of the projector some. This is the style I've got, the OEM dust caps don't fit on my headlights because of them, so I just went without. There is a little dust inside my headlights, since I was too lazy to mod the dust caps with a hole of some kind. The connections on the ballasts for this is a bit more bulky, and it's a twist lock type connection.

Here's a pic from my build thread. Had to do some major cutting, due to using Lexus RX350 OEM projectors, you won't need to do this with threaded shaft (universal fit) projectors.

The ballasts are in the engine bay, behind the headlights. They are way too big to be placed anywhere inside our assemblies. Plus, your bulbs are going to protrude out the back.

H1 bulbs have wires coming out, this connection is called AMP, your universal ballasts will have this same polarized dual connection. Often times they will come with a rubber grommet, and a 9006 plug as well. This is so you can feed the low beam bulb connection to it, which passes to the input of the HID ballast to activate it when your OEM low beams come on. Then the output of the HID ballast goes into the AMP connections of the HID bulb, to activate them.

D2 series bulbs don't have wires connected to them, but they still stick out of the projector some. This is the style I've got, the OEM dust caps don't fit on my headlights because of them, so I just went without. There is a little dust inside my headlights, since I was too lazy to mod the dust caps with a hole of some kind. The connections on the ballasts for this is a bit more bulky, and it's a twist lock type connection.

Here's a pic from my build thread. Had to do some major cutting, due to using Lexus RX350 OEM projectors, you won't need to do this with threaded shaft (universal fit) projectors.

l008com

Member

Guess who FINALLY ordered his projectors, only 3 years after starting this project. I got hung up on figuring out the best triggers for my LED DRL's that will go in the high beam bay. Once I see how to wire up the real lights, I'll either go without DRL, have the DRL's say on all the time including when the headlights are on, and just let that be that, or I'll go a little relay crazy and see if I can actually get the kind of DRL behavior I want (on with ignition, unless headlights are on). But I think once I can see stuff, this will be easier. So the projectors are on the way. I went with the $155 "super" acme's, not the $270 ones. At this point, it's an old truck and I just want to be able to see the road more than I care about looks so why spend the money.

Plus my old Camaros ('10 & '13) had very bright HID projectors and they were so bright, you couldn't even use the high beams because the reflective glare off road signs would blind you. I imagine that's what the $270 lights would be like.

Plus my old Camaros ('10 & '13) had very bright HID projectors and they were so bright, you couldn't even use the high beams because the reflective glare off road signs would blind you. I imagine that's what the $270 lights would be like.

l008com

Member

They just arrived!

There are an awful lot of little boxes in this large shipping box. This is going to be a little complicated, especially in the middle of winter. I'm sure I will have many, many questions.

But in the meantime, I do have one question. Once I figure out which setup to use to power my DRL's, and once I run that wire under the rug up towards the drivers area, is there a spot I can feed the line through the firewall to get it into the engine bay?

I am running some LED bulbs in the high beam bays as custom DRLs, so they will be directly powered, not connecting to any existing plugs etc.

There are an awful lot of little boxes in this large shipping box. This is going to be a little complicated, especially in the middle of winter. I'm sure I will have many, many questions.

But in the meantime, I do have one question. Once I figure out which setup to use to power my DRL's, and once I run that wire under the rug up towards the drivers area, is there a spot I can feed the line through the firewall to get it into the engine bay?

I am running some LED bulbs in the high beam bays as custom DRLs, so they will be directly powered, not connecting to any existing plugs etc.

is there a spot I can feed the line through the firewall to get it into the engine bay?

Oh, THIS is the fun part my friend! When I needed to run a pair of wires into the engine bay from a cabin switch, I had the same dilemma. From this first pic, you can see there's a non factory cable passing through a white grommet on the left. (this is looking between the driver's side fender and the master cylinder) A buddy of mine drilled a hole and put that there, helping me install my amp before I had enough tools of my own. I wanted to reuse that hole for the new wires, but couldn't figure out for the life of me how to reach it from under the dash.

I ended up taking a screwdriver, and poking holes in the OEM rubber boot, and using a wire snake to feed the blue and yellow wires through it. Took quite a bit of time and patience, since you can't tell how close you are to the hole on the other side. Having something like a giant sewing needle would have been ideal. I would suggest a wire clothes hanger for this, in hindsight.

Pulling the knee bolster down, and looking up above and to the left of the brake pedal.

l008com

Member

Oh, THIS is the fun part my friend!

I am quite certain you are lying to me

l008com

Member

Ok I've got a problem right off the bat. The low beams are connected to the relays. The high beams are connected to the projector itself, to remove the sheild. Well, I have not done the quad-beam hack, so when I turn on my high beams, my low beams turn off. Thus with this setup, I'll haven no high beams. I thought I already talked about this with TRS and they said it wouldn't be a problem. But unless I'm missing something, this ain't goona work?

Attachments

Correct, as currently setup, you would have to use flash-to-pass all the time for high beam functionality.

There are 2 ways to get around this.

There are 2 ways to get around this.

- Either do the quad beam mod, which is pretty easy, just get a diode, and maybe some short scraps of wire.

- You can add the fancy diode splitters with bulb connections on them. Those are much easier for the mod bug noobies, but they make everything much more cramped, and eat up a lot of space. Basically they connect to the high beam plug in the headlight, and send the signal to 2 places. 1 to the projector shield solenoid to move it, and the other to the low beam input on the relay harness, to keep the low beams powered. The diode keeps the low beams from turning on the high beams.

l008com

Member

Hey wait a minute, according to the diagram I posted above, this kit comes with high beam splitters? SO in theory i could just route the high beam second output to the low beam input and then high beams would power both the 'shade' and the actual bulbs, right? I wonder if that splitter has diodes built in. I need to ask TRS tomorrow what they suggest. But in the meantime, it is not clear what the difference is between the two diode options you suggest. Do you have links to each process?

The fuse block method is in the articles section of the forum. I think a few guys posted their own versions there (quad beam, 6 hi, and some similarly named titles). Basically you'd tie the coil of the high beam relay, to the coil of the low beam relay. Same exact logic, when the high beams are on, it also turns on the low beams to counter act the OEM function of the low beams turning off (from the BCM)

I don't think they offer splitters with diodes in them. They would be easy to tell, as there would be one of the sides with a diode spliced in, and shrink wrapped.

I don't think they offer splitters with diodes in them. They would be easy to tell, as there would be one of the sides with a diode spliced in, and shrink wrapped.

l008com

Member

Ok tonight I tried to lay out all of my parts and see how they go together. I have many questions and theretrofitsource is taking weeks to respond to my emails. So I'll make a list here and hopefully some of you guys can answer some of my questions.

- First and foremost, it is not clear to me how this projector installed in the lens. It is not clear how it attaches in the hole, which parts are needed, or how it all goes together. And none of these details are in the manual.

- The wiring makes even less sense. There is only one low beam input, and two high beams inputs. But what am I supposed to do with these? It looks like my lights each have a single 4 pin connector that carries high and low. Is there supposed to be some kind of harness adapter with this? The wiring on the bulb also is not clear, and doesn't seem to mach what's in the wiring diagram.

Would be easiest if you could post pics of all the components you have, that eliminates any misunderstandings from written descriptions.

1) I'm assuming you have some version of threaded shaft projectors, as those are the easiest to install and require little to no modification to the reflector bowls. Mini H1 projectors should be able to fit through the 9006 bulb opening as is. Mini D2S projectors have a much larger (diameter) shaft, and will require some Dremeling to enlarge the bulb opening in the reflector bowl.

There's 2 rubber washers on the shaft and a lock nut that should come pre-installed. The lock nut and last rubber washer need to come off, feed the projector through the reflector bowl, then reinstall the washer and lock nut (snugly but not real tight, you'll need to be able to twist/rotate for beam alignment later)

2) The 4 wire connections that enter the headlight are not touched in this mod. All connections use the 9006 and 9005 connectors from inside the headlights.

The single low beam connection accepts the input from the driver's side headlight. This triggers the relay harness, whose 2 outputs feed into the HID ballasts and gives you your normal low beam operation. The 2 high beam connectors are normally to be connected to the projector solenoid to drop the high beam shield out of the way, which we discussed already.

Since you did the quad beam mod, there's no need to introduce any splitters, or additional diodes like we talked about a few posts back. So when you're done with the connections, if you plan to run the stock dust covers, you'll need to mod the low beam ones to allow passage of the relay harness and HID input on the driver's side, and just the HID input on the passenger side.

1) I'm assuming you have some version of threaded shaft projectors, as those are the easiest to install and require little to no modification to the reflector bowls. Mini H1 projectors should be able to fit through the 9006 bulb opening as is. Mini D2S projectors have a much larger (diameter) shaft, and will require some Dremeling to enlarge the bulb opening in the reflector bowl.

There's 2 rubber washers on the shaft and a lock nut that should come pre-installed. The lock nut and last rubber washer need to come off, feed the projector through the reflector bowl, then reinstall the washer and lock nut (snugly but not real tight, you'll need to be able to twist/rotate for beam alignment later)

2) The 4 wire connections that enter the headlight are not touched in this mod. All connections use the 9006 and 9005 connectors from inside the headlights.

The single low beam connection accepts the input from the driver's side headlight. This triggers the relay harness, whose 2 outputs feed into the HID ballasts and gives you your normal low beam operation. The 2 high beam connectors are normally to be connected to the projector solenoid to drop the high beam shield out of the way, which we discussed already.

Since you did the quad beam mod, there's no need to introduce any splitters, or additional diodes like we talked about a few posts back. So when you're done with the connections, if you plan to run the stock dust covers, you'll need to mod the low beam ones to allow passage of the relay harness and HID input on the driver's side, and just the HID input on the passenger side.

l008com

Member

I'll reply in separate posts. First,

#1, here is my projector and all of its various parts. Literally nothing in the "instruction manual" showing what to do with these parts. Also I have to assemble the 'high beam' power connector myself. The instructions say the wires are polarity specific, but does not explain how to determine what the polarity is. I'm not even sure how I'm supposed to remove the metal bracket at the back of the threads so even insert this into the lens hole.

#1, here is my projector and all of its various parts. Literally nothing in the "instruction manual" showing what to do with these parts. Also I have to assemble the 'high beam' power connector myself. The instructions say the wires are polarity specific, but does not explain how to determine what the polarity is. I'm not even sure how I'm supposed to remove the metal bracket at the back of the threads so even insert this into the lens hole.

Last edited:

l008com

Member

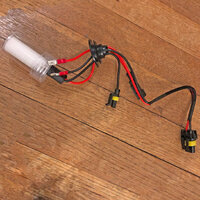

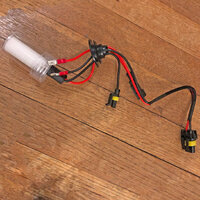

#1.5 The bulbs

These are the bulbs themselves. That's a lot of wires for one light. They all seem to be formed into that rubber grommet. The two single-connector plastic connectors seem to plug right into the ballast, which makes sense. What is the other connector all about? It's a two pin plastic connector at once end and two bare pins at the other end???

These are the bulbs themselves. That's a lot of wires for one light. They all seem to be formed into that rubber grommet. The two single-connector plastic connectors seem to plug right into the ballast, which makes sense. What is the other connector all about? It's a two pin plastic connector at once end and two bare pins at the other end???

l008com

Member

#2 The wire harness......

1 & 2) Power for the harness. Is the power connector for the under-hood fuse box a good place for that power pickup? Is there a specific place for the ground or does that go to any old grounding screw I can find?

3,4,5) The relays and the ballasts all have mounting brackets. How did you guys mount your boxes, and where? I mean I could just stick a self tapping screw into any old piece of metal I could find but that doesn't seem ideal?

6) So this connects to the driver's side #9, and the passenger side #9 gets taped up and not used?

7 & 8) As mentioned in my previous reply, I'm not sure what these mini harnesses are for? They don't seem to serve a function. Also, that rubber grommet... where exactly am I supposed to put that grommet?

9) See #6

10) So this connector goes directly to the projector's high beam shield on each projector?

11) So with the most simple installation, you still use this 4 pin connector unmodified. So both sides would plug in and then inside/behind each lens is where all the modifications happen?

12) This is an LED high beam sized DRL bulb I got. I plan on putting them in the high beam light bays but powering them with a directly line from another source. They are not headlights, they are low power 4500K LEDs just for DRL purposes.

Alternate Install:

Given all that, wouldn't it make more sense to do things like this: First, I'd have to get a bunch of male and female 2-pin and 4-pin connectors.

For the DRLs, I'd keep the internal high beam wiring inside the lens, but remove the low beam. I'd get a 4-pin connector that will plug into the lens, and hard-wire up only the high beam conductors to my custom relay, so that the DRL LEDs (installed inside the high beam lens bay) would be powered that way.

Then for the actual headlights, I would need..... a 4-pin connector that would plug into the factory headlight power connector, and then split into two 2-pin connectors, one going to connector #6 on the harness, and one going directly to the projector's high beam connection. Then on the other side, that custom harness would only have the high beam connection, not the low beam?

1 & 2) Power for the harness. Is the power connector for the under-hood fuse box a good place for that power pickup? Is there a specific place for the ground or does that go to any old grounding screw I can find?

3,4,5) The relays and the ballasts all have mounting brackets. How did you guys mount your boxes, and where? I mean I could just stick a self tapping screw into any old piece of metal I could find but that doesn't seem ideal?

6) So this connects to the driver's side #9, and the passenger side #9 gets taped up and not used?

7 & 8) As mentioned in my previous reply, I'm not sure what these mini harnesses are for? They don't seem to serve a function. Also, that rubber grommet... where exactly am I supposed to put that grommet?

9) See #6

10) So this connector goes directly to the projector's high beam shield on each projector?

11) So with the most simple installation, you still use this 4 pin connector unmodified. So both sides would plug in and then inside/behind each lens is where all the modifications happen?

12) This is an LED high beam sized DRL bulb I got. I plan on putting them in the high beam light bays but powering them with a directly line from another source. They are not headlights, they are low power 4500K LEDs just for DRL purposes.

Alternate Install:

Given all that, wouldn't it make more sense to do things like this: First, I'd have to get a bunch of male and female 2-pin and 4-pin connectors.

For the DRLs, I'd keep the internal high beam wiring inside the lens, but remove the low beam. I'd get a 4-pin connector that will plug into the lens, and hard-wire up only the high beam conductors to my custom relay, so that the DRL LEDs (installed inside the high beam lens bay) would be powered that way.

Then for the actual headlights, I would need..... a 4-pin connector that would plug into the factory headlight power connector, and then split into two 2-pin connectors, one going to connector #6 on the harness, and one going directly to the projector's high beam connection. Then on the other side, that custom harness would only have the high beam connection, not the low beam?

Last edited:

I'm at a conference this week, and the schedule is pretty packed all day so I won't be able to respond in detail until later. This video may help, also see if the steps in the description are better than the instructions you have

#1, here is my projector and all of its various parts. Literally nothing in the "instruction manual" showing what to do with these parts. Also I have to assemble the 'high beam' power connector myself. The instructions say the wires are polarity specific, but does not explain how to determine what the polarity is. I'm not even sure how I'm supposed to remove the metal bracket at the back of the threads so even insert this into the lens hole.

You have to keep in mind, this is a universal setup, there's an expected level of due diligence and planning that come before you buy, since there's no way for TRS to know exactly what you have ahead of time. Some of those bits, you won't need.

Yes, the high beam solenoid has to be wired up yourself. There's no connector, so you can cut a hole as small as possible in your reflector bowl, feed the 2 wires through and THEN attach the connector to them. You have a red and black wire, your standard positive and negative. The reason they say you have to determine the polarity, is because they don't/can't know what color wires you have that will be feeding it. For example, inside my headlights were orange and white wires for the low beams, green and black for the high beams. Also since the connector has a locking tab, you have to make sure you orient it correctly so not only do the wires line up, but the lock does as well.

#1.5 The bulbs

These are the bulbs themselves. That's a lot of wires for one light. They all seem to be formed into that rubber grommet. The two single-connector plastic connectors seem to plug right into the ballast, which makes sense. What is the other connector all about? It's a two pin plastic connector at once end and two bare pins at the other end???

The bulbs have that extra set of wires for potentially accepting the low beam input from inside the headlight, and sending that signal out to either a relay harness, or directly to the ballast input. Most of us discard those if they aren't 9006 pins, since you can't use them. If they were, you could a large hole in the dust caps big enough to feed the bulb through comfortably, and that rubber grommet would provide your seal.

1 & 2) Power for the harness. Is the power connector for the under-hood fuse box a good place for that power pickup? Is there a specific place for the ground or does that go to any old grounding screw I can find?

I recommend the battery, but the extra post on the front of the fuse block (where the infamous red wire goes) can be used too. Use the battery, or fender ground for ease.

3,4,5) The relays and the ballasts all have mounting brackets. How did you guys mount your boxes, and where? I mean I could just stick a self tapping screw into any old piece of metal I could find but that doesn't seem ideal?

Why would your idea not be ideal? The idea is to put them somewhere you can conveniently reach, where they won't be in the way of other stuff. I used self tappers, and mounted them on the back of the black plastic header panel. But when I replaced them last year, I just left them loose in the cavity behind the headlights. There's enough cabling from the power harness that they don't move around much.

6) So this connects to the driver's side #9, and the passenger side #9 gets taped up and not used?

The pins are inside a plastic connector, no need to tape them, they're already insulated from shorting against anything.

7 & 8) As mentioned in my previous reply, I'm not sure what these mini harnesses are for? They don't seem to serve a function. Also, that rubber grommet... where exactly am I supposed to put that grommet?

Optional. If you're so inclined, hang onto those extra leads for a future mod project.

10) So this connector goes directly to the projector's high beam shield on each projector?

11) So with the most simple installation, you still use this 4 pin connector unmodified. So both sides would plug in and then inside/behind each lens is where all the modifications happen?

Correct

Alternate Install:

I think you've bitten off a pretty good amount so far, may want to work on chewing this up first, before biting into more.

l008com

Member

The fight does not go well. That youtube video did help me understand which parts to use, but this porjector that was supposed to be a direct fit, does not seem to fit into the light at all. I'm really starting to regret this project. The insane amount of time and large amount of money is not going to be worth it just to have brighter headlights. But since their return policy is garbage, I guess I'm stuck with it. I'll post more pictures when I can.

l008com

Member

Ok I'm getting back to this project again and hopefully I can actually make some progress. So regarding the bowls, this is what mine look like up close. So am I just grinding that raised ring so its essentially flush with the rest of the bowl?

I added another picture so my question is more clear. Am I just grinding away the green highlighted part so its as flush as I can make it with the rest of the reflector?

I added another picture so my question is more clear. Am I just grinding away the green highlighted part so its as flush as I can make it with the rest of the reflector?

Attachments

You basically have 2 main objectives to achieve when it comes to making the projector "fit". The threaded shaft needs to be able to fit through the hole, and the projector needs to have zero movement once you tighten things to secure it.

The first objective is obvious. The second one, if you don't get that right, your beams will shake and vibrate on the road due to engine vibrations, and bumps in the road. Worse still, any looseness could allow rotational changes, and your cutoffs could become cockeyed. So if you can lock them in without grinding away extra material great. If not and you need more surface contact, then mod as needed.

The first objective is obvious. The second one, if you don't get that right, your beams will shake and vibrate on the road due to engine vibrations, and bumps in the road. Worse still, any looseness could allow rotational changes, and your cutoffs could become cockeyed. So if you can lock them in without grinding away extra material great. If not and you need more surface contact, then mod as needed.

l008com

Member

You basically have 2 main objectives to achieve when it comes to making the projector "fit". The threaded shaft needs to be able to fit through the hole, and the projector needs to have zero movement once you tighten things to secure it.

The first objective is obvious. The second one, if you don't get that right, your beams will shake and vibrate on the road due to engine vibrations, and bumps in the road. Worse still, any looseness could allow rotational changes, and your cutoffs could become cockeyed. So if you can lock them in without grinding away extra material great. If not and you need more surface contact, then mod as needed.

The threads fit in that hole just fine, no diameter adjustment is needed. However the threads aren't long enough to put a nut on if you insert the projector as is right now. The threads are basically flush with the back of the reflector.

the back of the reflector.

And since you don't need the plastic bulb locks, or the bulky raised section, back there the bulb rests against...

l008com

Member

What many people do, is free up space for the threaded section by grinding off the backside of the reflector bowl. It's out of sight, and no longer serves any purpose, so it doesn't need to be there. Plus if you need to tuck wires into the housing, this gives a little more room as well. If you looked at the first retrofit in my thread, you can see I did that. And I think a number of people in the big projector retrofit thread did the same. I don't remember how many pics are in that thread.