All Four Cycle Engines develop "Piston Slap" to some degree over time due to the need to have the Piston Wrist Pins to Connecting Rods slightly off-set to allow them to roll though Top Dead Center and keep their "Power Strokes" heading only in a Clockwise Direction.

The other factor contributing to this problem involves the shorter designs of modern engine piston skirts versus those of their 'longer cousins' from earlier engine designs.

Longer Piston Skirts were better at resisting the rocking action. However, they were naturally added unnecessary weight to fight against the motion of the Rotating Mass, making them less responsive to power demands while also being less fuel efficient.

As the Pistons in the 4.2L In-Line Six Cylinder Engines reach TDC... they bobble slightly, rocking suddenly from one side of the cylinder to the other, in line with the direction of rotation. This tendency can cause additional Piston Ring-to-Cylinder-Wall wear and adds to the actions that can oval out the upper cylinder walls.

Whenever engines are cold... the Pistons along with their

Low Tension Compression Rings contract enough to provide the added space to allow this rocking-slapping action to become more excessive. As the engine heats up, the Pistons and Rings expand and tend to lessen the "Piston Slap" effects up to a point.

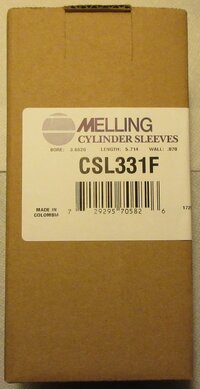

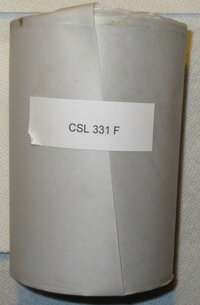

These images illustrate the wear conditions of the Cylinder Walls in a GM 4.2L LL8 Engine after 160,000 Miles and from exposure to the Dusty Air Environment of Arizona. Note the presence of an extra deep worn in oval where the Piston Head makes abrupt contact during the repetitive "Piston Slap" events as it digs into the Upper Cylinder Wall:

View attachment 102223View attachment 102224

The other artifact that can extend the lives of Modern Four Cycle Engines is having

Low Tension Compression Rings. These Rings can coax motors like the LL8 to last perhaps as long as 300,000 Miles or more if very well treated and serviced on schedule.

The "Old Chevy 265, 283, 327 and 350 CID" blocks would often require rebuilding right around 100,000 Miles or so because their Cast Iron Compression Rings were as "Thick as Re-Bar" and chewed quickly into Cylinder Walls... wearing out Motors rapidly and often leaving Rings or Ridges of Metal Deposited along the Upper Engine Block openings requiring "Ridge Cutters" just to remove the Pistons during rebuilding.

The down side of using these 'Low Tension Rings' is their tendency to

STICK TIGHTLY inside their Lands & Grooves of the Pistons after being exposed to

WAY TOO MUCH CARBON and un-burned Combustion By-Products that will literally Glue or Lacquer them right into the sides of the Pistons and thus, invites Excessive Gas Blow-By and increased "Piston Slap".

Proper Treatments using the ACDelco Top Engine Cleaner can dissolve these built-up Carbon Bonds, loosening them and returning the ability to flex and expand while better sealing the Two Top Compression Rings. This action can serve to increase compression, improve power, reduce fuel and engine oil consumption and reduce Gas Gum Deposits and Carbon Blow-By Products from 'Polluting and Diluting' the Engine Oil and collecting "Black Carbon Mung" all over down inside of the lower Crankcase.

Excessive Gas Blow-By can also seriously reduce the lubricity and protection of Motor Oil and along with Dirty Air Filtration, it invites excessive engine wear over time. Changing one's Motor Oil in this LL8 Engine every 3,000 Miles should be done for these and other reasons using Mobil1 FULL Synthetic and either Mobil1 or K&N Oil Filters.