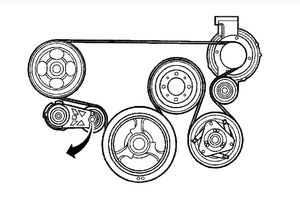

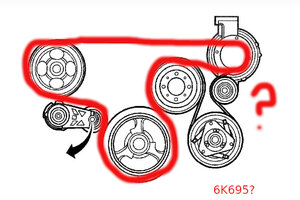

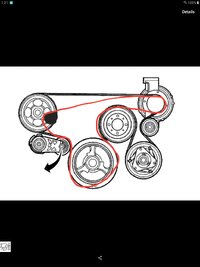

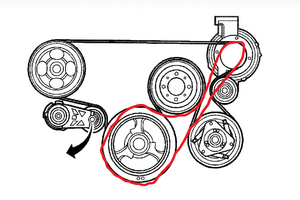

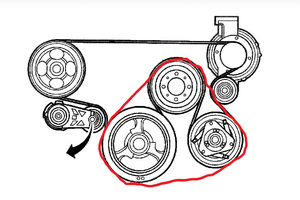

Its going to come down to positioning. If you are using the OE style alternator, in its current location, your problem comes from the idler puller below the alternator. It now needs to be a tensioner, and its not notched in the back for that, and it doesnt give the water pump a lot of belt time traction.

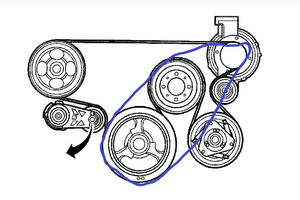

From what I can see, it would be better to move the alternator to the AC compressor location, as that would give the most contact to all pulleys (Water pump, crank, alternator), while keeping all the pulleys turning in the correct way, and to figure out a way to mount a tensioner where the current idler pulley is.

It would then be the shape of a triangle, crank and alternator on the bottom, with the water pump being above them, centered.