Sorry to hear you're still having issues.

However, after reading through your latest post... I think you're tackling *different* issues, IMHO -- engine related (fuel / air / timing).

It may be that the pressure relief valve was 'masking' the idle issue, if you will. But it was there all along, and now that you fixed the valve / pump, it shows itself easier.

You mentioned cleaning the throttle body (and that's a good plan; I'd check that, too). But -- did you remove it from the intake, and clean the rear side of it? I know it can be a pain, especially if the coolant runs through the bottom of it -- but it really needs to be cleaned from both sides.

WRT the pump / trans and your idle -- it really shouldn't affect it. The trans is 'acted upon' by the PCM / engine / load conditions -- whatever feedback it sends doesn't correlate into engine RPM. And if the pump were stuck, per se -- the torque of the engine / flywheel would overcome the resistance of the TC / pump. In short, it's not going to make your engine run slower, by itself.

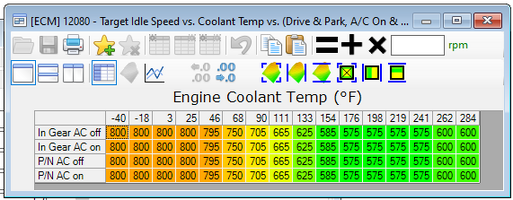

If your engine controls are like mine, your stated RPM are a bit low, IMHO. You should be in the neighborhood of 750-850 rpm @ idle. I'll dig up my HPT tables and edit this post, showing the cold / hot idle that the PCM will command (mine is altered in some cells, but only by about 50 RPM, if that). Yes, I have the 6.0L, and a P59 PCM -- but yours should be similar, I would think.

With that said... how to fix? Other than writing the PCM to command those speeds (if different), you're going to be looking for what's making them slower. Bad throttle body? Out of sync with TPS? Blockage or missing vacuum hose? It'll be a puzzle, to be sure.

(Will edit this post with the table info I reference, above.)

On edit: Here's the table I was referring to. X-axis is the coolant temp.

View attachment 103228

This is from my 'stock' factory file read. You can see that we're talking 800-750rpm is the norm here. You don't start getting into the upper 500s until you're at 154F. Which brings up a question -- your coolant temp sensor (CTS). Could it be on the fritz, indicating a higher-than-actual temp?

One more table to look at:

View attachment 103229

This one, I won't comment on at length, as I don't know all the nuances of it. From the 'tool tips' that show up in the HPT software, this references the speed (at or below) which 'stall saver' programming will kick in to keep the engine running. One thing of note -- the tables have the same values, whether in gear, or in Park / Neutral. Just something to consider, since we're talking about idle speed.

Finally, going back to the trans line pressure, and how reverse was showing higher line pressure -- that's normal. Pressure will be highest in reverse, and the pressure you're referencing looks just about spot on, IIRC.

My post isn't 'the fix'... but hopefully, it will give you some good info to move forward with.

BTW, there are a ton of other parms, etc., in HPT concerning AFR, etc. The above are just a couple of parameters I thought of, as I read through your post.