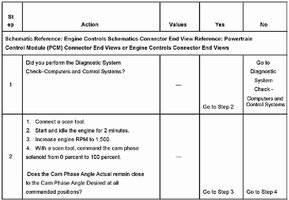

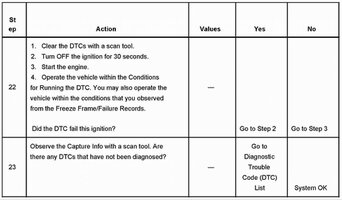

Okay since mid october I have been battling a P0014, at the time it had a P0017, and a P0128, those two have gone away. I have replaced the VVT 2x with a dorman and still got the code, so I broke down and got an ACDelco from the dealership, two weeks ago and replaced it. I have changed the oil twice since October. I have also replaced the thermostat which was stuck open, camshaft sensor last week, replaced the crankshaft position sensor and took it to a shop to do the CASE relearn ( which he didn't charge me for)?

The mileage on the truck is about 127,000.

I put off an oil change which really gummed up the original VVT. Right now there is STP 5w30 and stp filter.

Added Seafoam to crankcase and waiting for about a hundred miles or so to rechnage the oil. Then after that I guess its a dealer or shop unless I can get it figured out. Thanks, in advance.

The mileage on the truck is about 127,000.

I put off an oil change which really gummed up the original VVT. Right now there is STP 5w30 and stp filter.

Added Seafoam to crankcase and waiting for about a hundred miles or so to rechnage the oil. Then after that I guess its a dealer or shop unless I can get it figured out. Thanks, in advance.