limequat said:Yep. From what I understand the airflow calculation uses a blend of MAP and MAF at low load and then switches exclusively to MAF in high load.

If I was going to do it over, I think I would add the 2 bar in addition to the 1 bar. The switch COMPLETELY fubar'd the VE tables. It wasn't a straight scalar. On the flipside, you can keep your stock MAP, scale a 4" MAF and have a nearly stock quality tune just like that for up to 12 psi.

Exactly my plan. We have the same understanding. Why do you say 12 psi limit?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

4200 Turbo Supra

- Thread starter limequat

- Start date

ScarabEpic22

Member

- Nov 20, 2011

- 728

bruhaba said:OK, basically just to log it. My 06 should just carry out the last value of the ve table. I wouldn't think it's a problem like Lime said, the MAF takes care of it. Great idea though to be able to log it.

That method works OK, but ONLY IF you have an 06-07! 02-05 P10s do not have a MAF, once you get into boost 1) the PCM will go into REP (unless you tune it) and 2) whatever your 100% fueling value is at that RPM is what you will get whether you're at 100 kPa or 150 kPa (read you will be SUPER lean in boost). You need to use a rising rate FPR and do something to set your spark timing.

These PCMs arent nearly as easy to do boost with as the V8 PCMs or 08-09 I6s. Heck, the 08-09s just need a 2 Bar MAP and you can set your fueling without an issue up to 2.5 Bar.

- Dec 8, 2011

- 520

So, a new (professionally) welded aluminum oil pan is on the Supra. I welded up the up-pipe to manifold connection and put her all back together again. Been fighting laziness and a dead battery. I fired it up and it was running rough. Really lean. Trying to tune it last year with the hole in the up-pipe screwed things up. But the PCM is correcting, and it smooths out pretty nice after a couple of minutes. What the hell lets go for a drive!

The 4200 devoid of any torque management or torque converter is incredibly responsive. Add boost and it becomes tough to control ones self. So when I first eased her out onto the pavement it was less of a "easing" and more of a full throttle, fishtailing launch. And then: BANG! The power was gone. The engine got rough and didn't want to idle. I came to a light and tried to heal-toe to keep the revs up while still stopping, but it stalled. Turn the key, <click>. Damn.

A good Samaritan was kind enough to help me push it out of the road. He even offered to help diagnose the problem. When I popped the hood he couldn't get away fast enough. "Oh I used to know a little bit about the older ones." The Supra is now knocking on 30 years old. So the above picture is my wife saving my bacon.

Turns out the BANG! was top and intermediate boost pipes saying adieu. With no solid connection of intake pipes, the MAF was insistent that there was zero airflow and the PCM delivered fuel accordingly. In the end, I fudged the injector scalar just to get it started and limped back home.

Fast forward to this morning. The I/C pipes are cranked down 'bout as hard as I can manage, and there's about 30% more fuel in the tune at idle. Battery is charged. The engine rolls over twice, catches and settles into a smooth idle that only I6s can do. The PCM is hardly adjusting the mixture at all. So far so good. Up and down the driveway, no hiccups. She wants to run. We set out to the dirt roads around my house where I subject my neighbors to a series of 1st gear half throttle pulls: BrrrrrrrrrRRRRRR WHOOOOSHHH!

As I round the bend en route to my drive way, I can't take it anymore. I roll into the throttle at 3k rpm. The VVT turbo is instantly on the case. After about a second and a half -even though I haven't even hit WOT- the big GT37 is blowing 9 psi and the 275/45/17s are fighting for something to grab onto.

Oh my dear Mary mommy of Mohommad it is so... BANG! The steering goes stiff and the throttle is dead. I coast it into it's perenial parking spot and turn it off.

Until next time, Supra. You nasty tease.

The 4200 devoid of any torque management or torque converter is incredibly responsive. Add boost and it becomes tough to control ones self. So when I first eased her out onto the pavement it was less of a "easing" and more of a full throttle, fishtailing launch. And then: BANG! The power was gone. The engine got rough and didn't want to idle. I came to a light and tried to heal-toe to keep the revs up while still stopping, but it stalled. Turn the key, <click>. Damn.

A good Samaritan was kind enough to help me push it out of the road. He even offered to help diagnose the problem. When I popped the hood he couldn't get away fast enough. "Oh I used to know a little bit about the older ones." The Supra is now knocking on 30 years old. So the above picture is my wife saving my bacon.

Turns out the BANG! was top and intermediate boost pipes saying adieu. With no solid connection of intake pipes, the MAF was insistent that there was zero airflow and the PCM delivered fuel accordingly. In the end, I fudged the injector scalar just to get it started and limped back home.

Fast forward to this morning. The I/C pipes are cranked down 'bout as hard as I can manage, and there's about 30% more fuel in the tune at idle. Battery is charged. The engine rolls over twice, catches and settles into a smooth idle that only I6s can do. The PCM is hardly adjusting the mixture at all. So far so good. Up and down the driveway, no hiccups. She wants to run. We set out to the dirt roads around my house where I subject my neighbors to a series of 1st gear half throttle pulls: BrrrrrrrrrRRRRRR WHOOOOSHHH!

As I round the bend en route to my drive way, I can't take it anymore. I roll into the throttle at 3k rpm. The VVT turbo is instantly on the case. After about a second and a half -even though I haven't even hit WOT- the big GT37 is blowing 9 psi and the 275/45/17s are fighting for something to grab onto.

Oh my dear Mary mommy of Mohommad it is so... BANG! The steering goes stiff and the throttle is dead. I coast it into it's perenial parking spot and turn it off.

Until next time, Supra. You nasty tease.

- Dec 8, 2011

- 520

I hung a bracket down from the block that retains the boost tube. It's a single mount point on each end, so there's plenty of play, but not in the direction that would allow the tubes to separate like they were before.

Here's the attachment on the boost tube, which I now realize looks a lot like a robot nipple.

Here's the attachment on the boost tube, which I now realize looks a lot like a robot nipple.

- Dec 8, 2011

- 520

Ok, so we already know that limequat's welds look like shit. The question is, does it hold boost now.

Well...

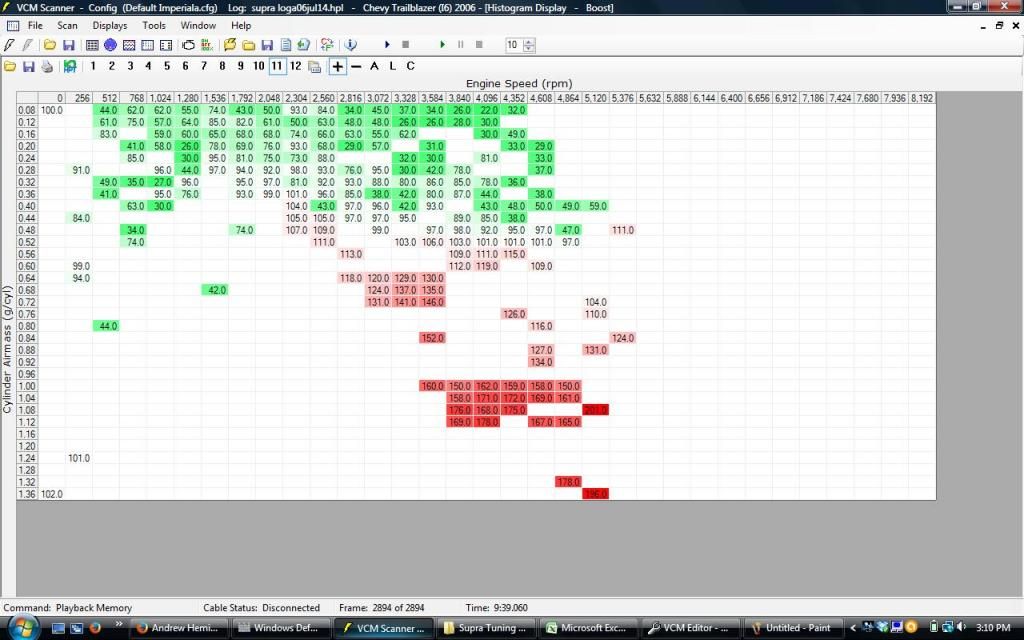

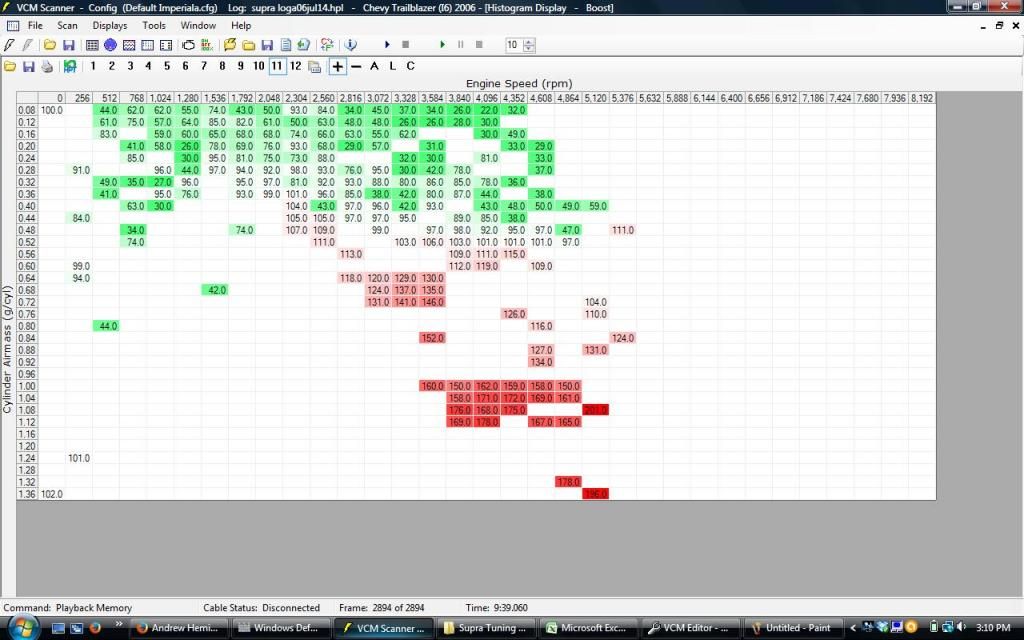

Here's a HPTuners histogram that shows peak manifold pressure in KPA for each point of the spark map (RPM vs Load):

So...the numbers are a bit small, but -yeah- at least one of the squares starts with a '2'. As in 15 psi. Oops! Sorry, Supra!

So, yes, the tube mod holds boost. No, the boost controller is not quite dialed in, lol!

Other factoids: positive pressure by 2300 RPM. What should be max boost by 3000 RPM. Pulls HARD. Like scary hard.

Well...

Here's a HPTuners histogram that shows peak manifold pressure in KPA for each point of the spark map (RPM vs Load):

So...the numbers are a bit small, but -yeah- at least one of the squares starts with a '2'. As in 15 psi. Oops! Sorry, Supra!

So, yes, the tube mod holds boost. No, the boost controller is not quite dialed in, lol!

Other factoids: positive pressure by 2300 RPM. What should be max boost by 3000 RPM. Pulls HARD. Like scary hard.

- Dec 8, 2011

- 520

Wow, long time no update.

In the past two years, I sold my driver Saab 92-x. The Supra got pressed into daily driver duty November - December 2014. Turns out the turbo was so responsive because the vanes were stuck shut. So it was acting like a really small turbo all the time. Which is great until about 4000 rpm. I unplugged the controller and ran it with the vanes full open. Even like this, it makes 5-8 PSI, but not until over 4000 RPM.

Jan 2015 a new Mustang Ecoboost became my DD and I lost interest in the Supra. Nothing happened for about a year.

2016, I wanna tinker again and I added some features to my ever-frustrating boost controller. Worked on the software some and added an RPM input so I can fudge airflow based on engine speed and MAP. I figured out my vane position sensor was dead and replaced that.

Parked the mustang in June and started driving the Supra again. Boost controller is still not right, but it's fun anyway.

After a couple weeks the engine develops a nasty knocking sound. Damn. I'm about ready to push the thing off a cliff when I get a P0017. This is not a coincidence.

In the past two years, I sold my driver Saab 92-x. The Supra got pressed into daily driver duty November - December 2014. Turns out the turbo was so responsive because the vanes were stuck shut. So it was acting like a really small turbo all the time. Which is great until about 4000 rpm. I unplugged the controller and ran it with the vanes full open. Even like this, it makes 5-8 PSI, but not until over 4000 RPM.

Jan 2015 a new Mustang Ecoboost became my DD and I lost interest in the Supra. Nothing happened for about a year.

2016, I wanna tinker again and I added some features to my ever-frustrating boost controller. Worked on the software some and added an RPM input so I can fudge airflow based on engine speed and MAP. I figured out my vane position sensor was dead and replaced that.

Parked the mustang in June and started driving the Supra again. Boost controller is still not right, but it's fun anyway.

After a couple weeks the engine develops a nasty knocking sound. Damn. I'm about ready to push the thing off a cliff when I get a P0017. This is not a coincidence.

- Dec 8, 2011

- 520

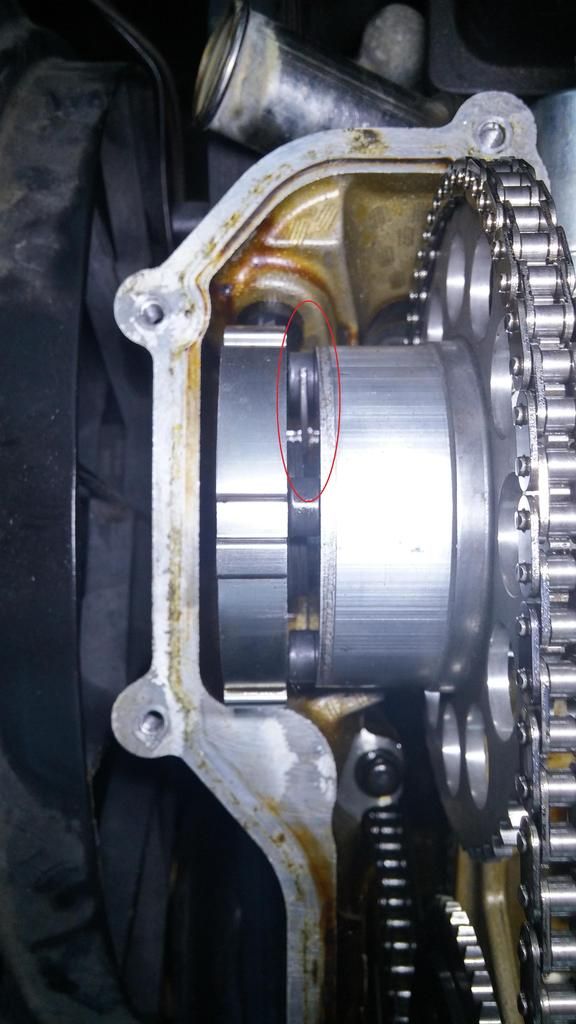

I pulled the CPAS hoping to fixe the P0017. It did have aluminum chips in the screens, but it didn't fix my problem.

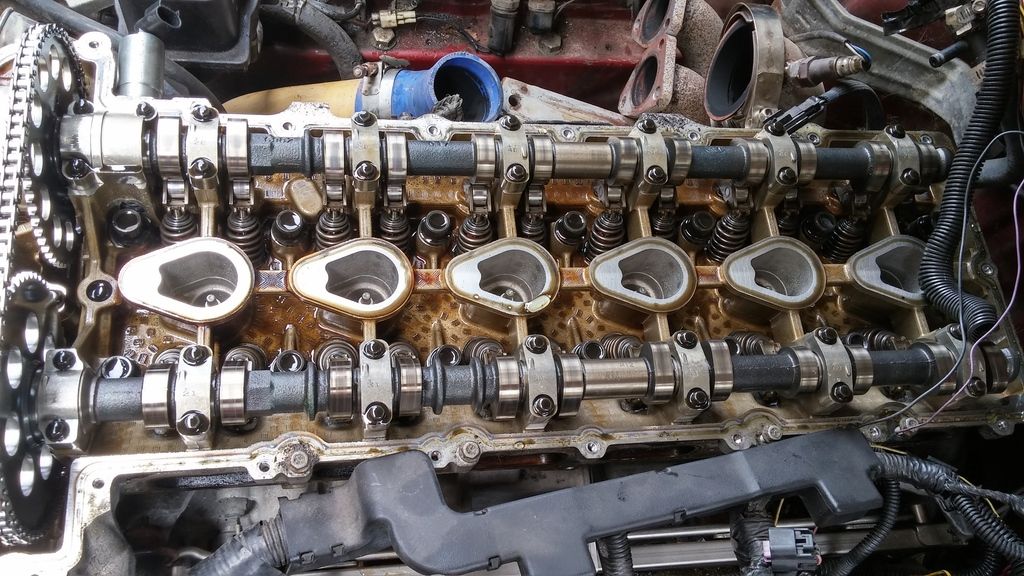

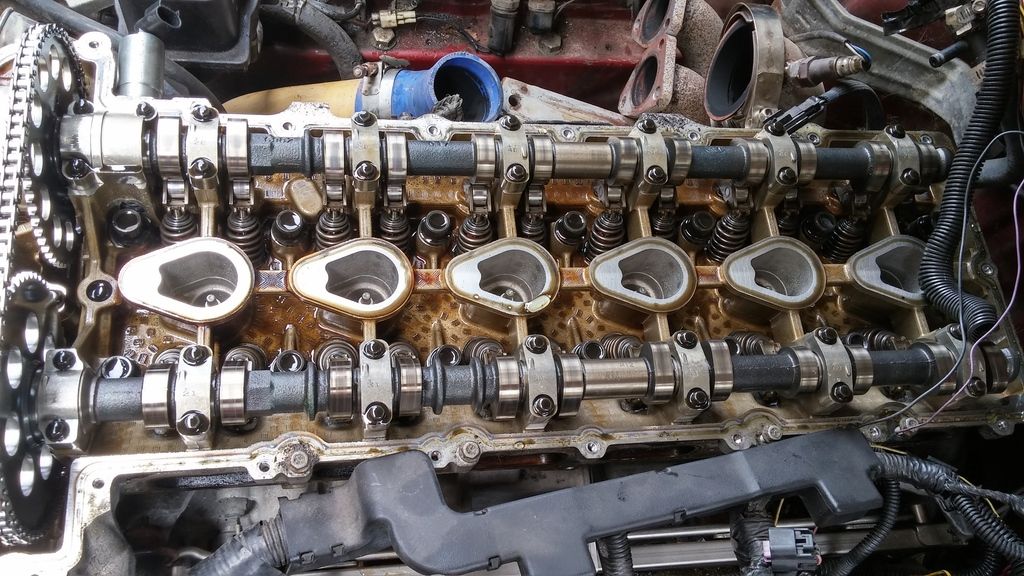

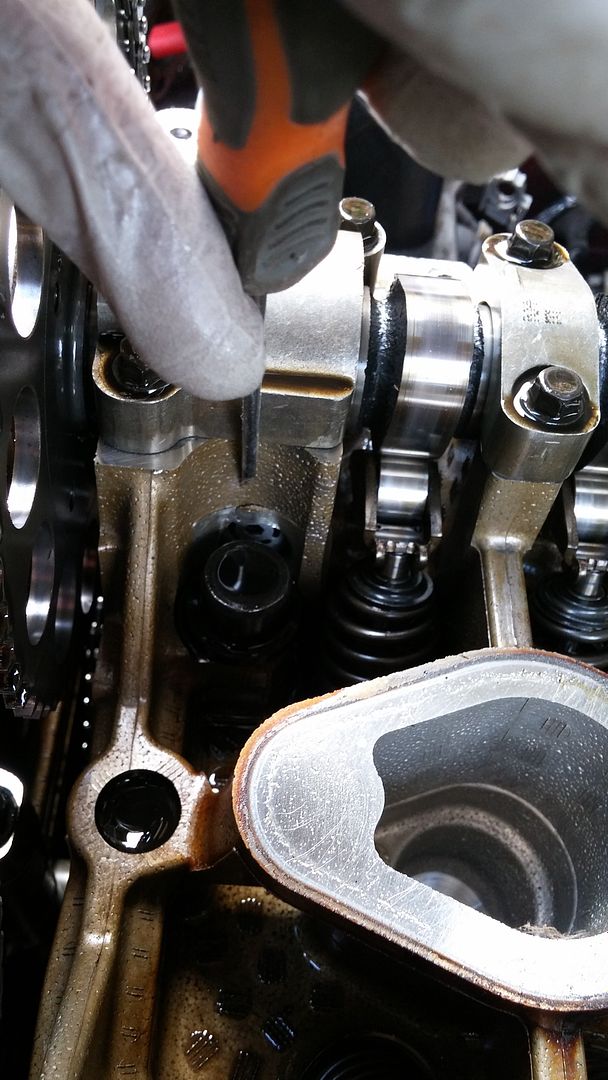

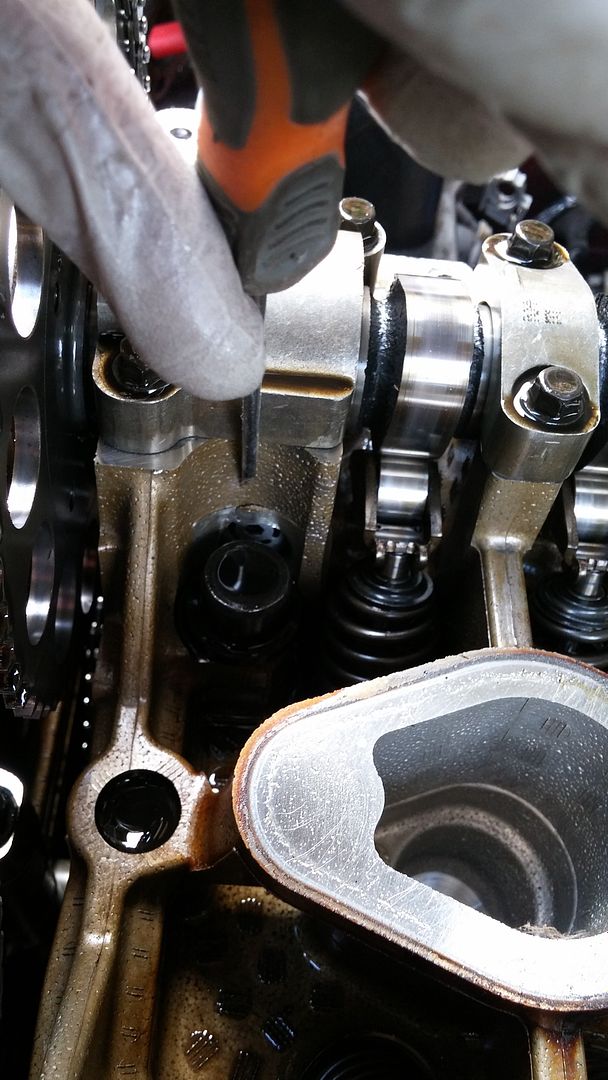

Next I tried commanding various cam positions with HPTuners. It couldn't do it. The cam would bounce around between 0 and 25 degrees. It's gotta be the phaser, so the teardown begins...

I got down to the valve cover. For me, that means first intercooler pipes, then alternator, then intake manifold, and finally the turbo. I tried to tuck the turbo close to the head for packaging, but it doesn't make service any easier.

Engine still looks pretty clean. Some scoring on the cam lobes, hopefully normal.

I don't have a timing chain guide on top of the sprockets. Is that just on earlier heads? Is it an upgrade?

Next I tried commanding various cam positions with HPTuners. It couldn't do it. The cam would bounce around between 0 and 25 degrees. It's gotta be the phaser, so the teardown begins...

I got down to the valve cover. For me, that means first intercooler pipes, then alternator, then intake manifold, and finally the turbo. I tried to tuck the turbo close to the head for packaging, but it doesn't make service any easier.

Engine still looks pretty clean. Some scoring on the cam lobes, hopefully normal.

I don't have a timing chain guide on top of the sprockets. Is that just on earlier heads? Is it an upgrade?

- Dec 8, 2011

- 520

Here's what my manifold looks like now. The high temp engine paint is doing only slightly better than the ceramic coating. I may try anti-seize next.

I also found an exhaust leak at the AIR port where I mounted my turbo bracket. I'll have to goop that up with loctite or something.

This is the underside of the valve cover. I'm checking to see if the chain made contact. There are some ever-so-slight marks where the grease is removed, but it barely penetrates the aluminum if at all. This valve cover is from a different engine, the marks could have already been there. But it makes me wonder about the missing top timing chain guide.

I also found an exhaust leak at the AIR port where I mounted my turbo bracket. I'll have to goop that up with loctite or something.

This is the underside of the valve cover. I'm checking to see if the chain made contact. There are some ever-so-slight marks where the grease is removed, but it barely penetrates the aluminum if at all. This valve cover is from a different engine, the marks could have already been there. But it makes me wonder about the missing top timing chain guide.

Huh, must have been a cost-save. Thanks for checking!

Seems to be alot of that with this platform. Thought it was just emblems, hood/glove box lights, and cabin air filters. Now timing chain guides on top on the motor as well. lol...

- Dec 8, 2011

- 520

The head is cracked!!

Well, not the way you might think.

It looks like there's a very small area where the oil passage is machined for the VVT and also clearanced for a head bolt.

I picked at it with the screwdriver, and it came off. Better now than later!

Well, not the way you might think.

It looks like there's a very small area where the oil passage is machined for the VVT and also clearanced for a head bolt.

I picked at it with the screwdriver, and it came off. Better now than later!

Mooseman

Moderator

- Dec 8, 2011

- 520

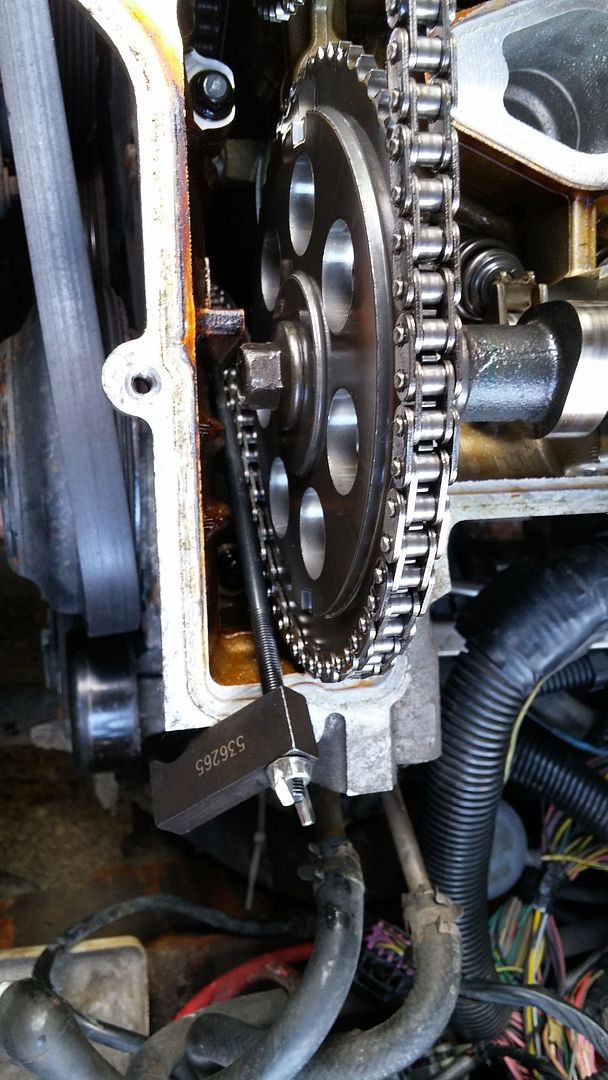

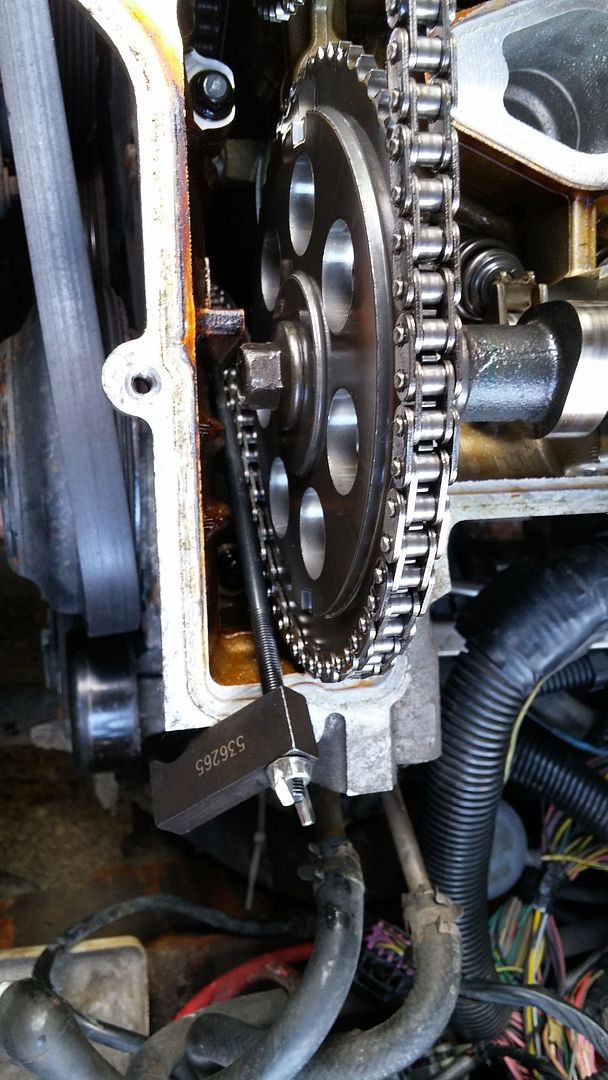

Here's the service tools installed. After I used them, I can't believe that I considered not using them. The ends have to be just perfect to fit into the chain, and then make a 90 to get around the sprockets and back up to the head. They'll probably sit on my shelf for the next 40 years, but totally worth it.

Is this pokey thing supposed to rattle?

Is this pokey thing supposed to rattle?

Mooseman

Moderator

Mooseman

Moderator

- Dec 8, 2011

- 520

Uh, no. Is that original? I had to replace mine twice. I have a Dorman now and it's been good.

Yep it's the original part. I shook and twisted the new part and it did not rattle. Also with the new part I was able to twist it through it's range. The old part I could only twist a couple degrees before it clinked and stopped moving.

So I'm pretty confident that the phaser is the root cause of the problem. But why did it fail? I wonder if they don't like 7k rpm?

Mooseman

Moderator

Quite possible. Lots of forces going on at that RPM.

My original one failed for an unknown reason as it was in the used replacement engine. Could have been poor maintenance as there was some caked on oil. Nowhere near as clean as yours. The second one could have been of my own doing when I replaced the timing chain tensioner.

It's a mechanical part and as such, they do fail.

My original one failed for an unknown reason as it was in the used replacement engine. Could have been poor maintenance as there was some caked on oil. Nowhere near as clean as yours. The second one could have been of my own doing when I replaced the timing chain tensioner.

It's a mechanical part and as such, they do fail.

AtlWrk

Member

- Dec 6, 2011

- 674

Yep it's the original part. I shook and twisted the new part and it did not rattle. Also with the new part I was able to twist it through it's range. The old part I could only twist a couple degrees before it clinked and stopped moving.

So I'm pretty confident that the phaser is the root cause of the problem. But why did it fail? I wonder if they don't like 7k rpm?

Only one way to find out: open her up and show us!

- Dec 8, 2011

- 520

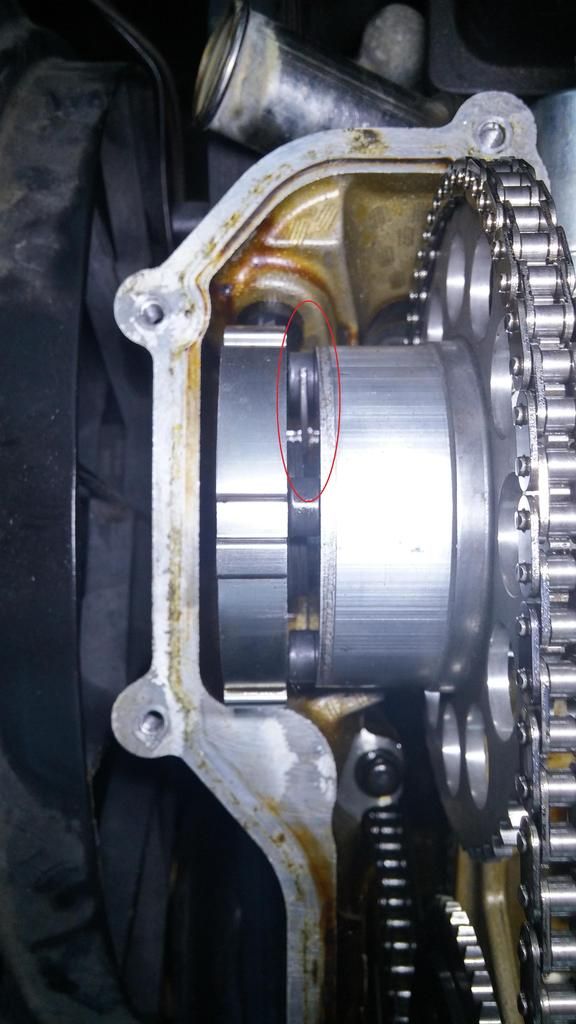

Popped this piece off with two screwdrivers. It's a very light press, you could almost get it by hand

At this point the rattle is gone. So it must have been the spring. Going further, taking off the cover...

You can see the 4 vanes. The one vane is larger because it incorporates the lock pin. Speaking of which, the lock pin is the reason why I couldn't rotate the phaser. I'm not sure why I could on the new part. I went back and tried it again (now installed on engine) and I could not rotate the new one either. Perhaps they ship with the pin not locked?

And fully disassembled. The lock pin receptical is the circle in the top of the housing. the mate on the rotor is just a pin with a spring on it. When there's oil pressure, the spring is pushed back into the rotor and the rotor is free to move.

This seems to be my problem. You can see where it engages on the timing hub, but there is no corresponding feature for the housing.

- Dec 8, 2011

- 520

So what am I missing? The spring must act on the housing but there are no features for it do so. The cover is perfectly flat with no features... unless you count the bolts!

Back out to the car to check the new part. Fuck me, there it is right in front of my face!

So my initial feeling was correct. Return spring broken on phaser, resulting in poor cam control.

Yay! I figured it out and it's not a rod! But where is the other half of the spring?

Back out to the car to check the new part. Fuck me, there it is right in front of my face!

So my initial feeling was correct. Return spring broken on phaser, resulting in poor cam control.

Yay! I figured it out and it's not a rod! But where is the other half of the spring?

Mooseman

Moderator

So which one did you get? The GM reman or a new Dorman?

There seems to be two different types of the phasers from Delphi. One with the spring exposed and the other not. Check out this thread on the Dorman and my old one: http://gmtnation.com/forums/threads/dorman-now-has-vvt-cam-phaser.14839/

There seems to be two different types of the phasers from Delphi. One with the spring exposed and the other not. Check out this thread on the Dorman and my old one: http://gmtnation.com/forums/threads/dorman-now-has-vvt-cam-phaser.14839/

- Dec 8, 2011

- 520

So which one did you get? The GM reman or a new Dorman?

There seems to be two different types of the phasers from Delphi. One with the spring exposed and the other not. Check out this thread on the Dorman and my old one: http://gmtnation.com/forums/threads/dorman-now-has-vvt-cam-phaser.14839/

Right they introduced a new vane type phaser ... I thought it was 2006 with all the other changes, but it might have been 2005. Yours was a helical type. Meaning there was curved spline. The vane type has the spring exposed and was no doubt a cost save over the helical type.

I was not aware they were interchangeable. The vane is axially shorter, since it doesn't need to be pushed the length of the spline. The 2006 head was shrunk around the phaser and is actually slightly smaller. This is also the reason 2002-2005 trucks can't upgrade to the aluminum valve cover (and better coils).

Anyway, mine is a GM part. I found a seller on Amazon that was clearing stock and I got it for $60 shipped

Mooseman

Moderator

Very good deal on that phaser.

On my comparison of the Dorman phaser, it was just as long as the original so I think they made the vane type to fit the older engine. Hopefully it's better than the original.

On my comparison of the Dorman phaser, it was just as long as the original so I think they made the vane type to fit the older engine. Hopefully it's better than the original.

- Dec 8, 2011

- 520

Wow, another two years gone by.

So, since our last update I determined that the rod was knocking in addition to the phaser clanking around. The engine is pulled back out, and now I'm trying to figure out what happened.

Here's video of me checking out the bearings. Definitely at least one bearing spun.

So, since our last update I determined that the rod was knocking in addition to the phaser clanking around. The engine is pulled back out, and now I'm trying to figure out what happened.

Here's video of me checking out the bearings. Definitely at least one bearing spun.

Mooseman

Moderator

- Dec 8, 2011

- 520

So that new phaser also bit the dust?

AFAIK, the phaser is fine. The head still looks pristine. My current theory is that the oil pump couldn't keep up with my oil-controlled variable vane turbo.

Mooseman

Moderator

- Dec 8, 2011

- 520

Not sure about turbo's, but could an oil accumulator of some type be plumbed in to assist with the drop in volume/pressure from the turbo?

I don't know about that, seems like it would be worth looking into. I do know that several people have run turbos on an Atlas with no oil supply issue. One difference with my setup was that the turbo was lubricated *and* controlled by the oil. I'm planning to ditch the variable-vane turbo and shim the oil pump on the next motor.

I_Shoot_Back

Member

Do you have a build threat on this setup? Very interested in turbo'ing a 4200. Was waiting for capone's batmobile to be turbo'd but i think that project is on hold for a bit.

- Dec 8, 2011

- 520

Do you have a build threat on this setup? Very interested in turbo'ing a 4200. Was waiting for capone's batmobile to be turbo'd but i think that project is on hold for a bit.

Well, the duration of this project spans several message boards, lol! Also, everything was hosted with photobucket, so most of the pics are now lost. Anyway, my first and remaining build thread is back at trailvoy:

https://forums.trailvoy.com/showthread.php?t=51636&page=1

I_Shoot_Back

Member

thank you  Will spend some time and read that. Skimmed through it for a bit and can see a lot of pic's still,I got this app for firefox that somewhat restores the link to pb

Will spend some time and read that. Skimmed through it for a bit and can see a lot of pic's still,I got this app for firefox that somewhat restores the link to pb

Will spend some time and read that. Skimmed through it for a bit and can see a lot of pic's still,I got this app for firefox that somewhat restores the link to pb

Will spend some time and read that. Skimmed through it for a bit and can see a lot of pic's still,I got this app for firefox that somewhat restores the link to pbThat's exactly what we plan to do with the oil pump for my build. Use a brand new Mahle/Clevite pump and add a shim. Spare motor will be completely freshly rebuilt just for this turbo build. Still quite a long time away from even starting, life and/or money gets in the way as usual....shim the oil pump on the next motor.

- Dec 8, 2011

- 520

^ I hear you Capote. I_Shoot_Back, that's cool you have a work around for the photobucket problem! I should probably go through and rehost those pictures.

SO...

At this point I don't think there's much more I can do -investigation wise- Other than pull the crank and check the oil passage to the #6 rod. That will be a pain, as I don't think I can pull the crank with it on the stand (rear main seal is obstructed). Also, I have room in my garage for precisely ONE straight 6. Plan is to pull it to pieces and stash them in the basement. Then order up a replacement 08-09 engine. Then maybe rebuild this one in parallel.

Here's some dreams I have about a rebuild:

* liners from a 2006 3.7 I5 to make a 4.4l I6

* Car-sized cam/crank sprockets, so I can make the valve cover smaller

* dual VVT

* stock crank, but forged rods, pistons

* head port

* cam regrind

SO...

At this point I don't think there's much more I can do -investigation wise- Other than pull the crank and check the oil passage to the #6 rod. That will be a pain, as I don't think I can pull the crank with it on the stand (rear main seal is obstructed). Also, I have room in my garage for precisely ONE straight 6. Plan is to pull it to pieces and stash them in the basement. Then order up a replacement 08-09 engine. Then maybe rebuild this one in parallel.

Here's some dreams I have about a rebuild:

* liners from a 2006 3.7 I5 to make a 4.4l I6

* Car-sized cam/crank sprockets, so I can make the valve cover smaller

* dual VVT

* stock crank, but forged rods, pistons

* head port

* cam regrind