- Dec 12, 2011

- 4,673

2004 TB 4.2, 200K miles, religious oil changes at 5-6K with Mobil-1.

I was helping a buddy with the stepper motors and heard a light tap, owner was unaware and if you stand in front you can't hear it

Obviously with the recording being a few inches from the bell housing, it's very audible. Had light glitter in oil, and I can't tell if it's a rod or pin. Nothing overly telling on the stethoscope around the pan or side of block.

Here's the video:

I pulled the pan and only have removed the #5 &6 caps, had to finish up early. With an oily surface, (not cleaned) I have

0018" clearance, maybe .0019 if cleaned up. #5 journal looks brand new, #6 had very light marks but nothing you can feel.

The knock is roughly 5-6 Hz, but hard to tell if it's a double-tap from a pin, also a little deep for a pin.

Could this be the very beginning of a rod bearing failure?

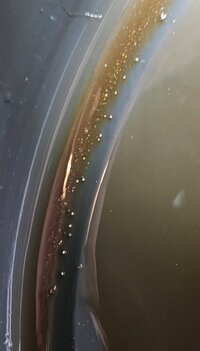

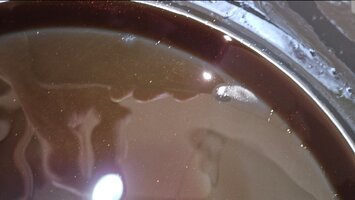

Here's the #6 journal

#6 lower bearing

The bearing looks ok, but when do these motors start to have an audible knock? Since max spec is .0025'

I still need to pull 1-4, but what's odd is the noise is from the bell housing area. Converter bolts are tight, and I can't see any cracks in the flexplate.

Open to all thoughts.

I was helping a buddy with the stepper motors and heard a light tap, owner was unaware and if you stand in front you can't hear it

Obviously with the recording being a few inches from the bell housing, it's very audible. Had light glitter in oil, and I can't tell if it's a rod or pin. Nothing overly telling on the stethoscope around the pan or side of block.

Here's the video:

I pulled the pan and only have removed the #5 &6 caps, had to finish up early. With an oily surface, (not cleaned) I have

0018" clearance, maybe .0019 if cleaned up. #5 journal looks brand new, #6 had very light marks but nothing you can feel.

The knock is roughly 5-6 Hz, but hard to tell if it's a double-tap from a pin, also a little deep for a pin.

Could this be the very beginning of a rod bearing failure?

Here's the #6 journal

#6 lower bearing

The bearing looks ok, but when do these motors start to have an audible knock? Since max spec is .0025'

I still need to pull 1-4, but what's odd is the noise is from the bell housing area. Converter bolts are tight, and I can't see any cracks in the flexplate.

Open to all thoughts.

Last edited: