Hello all. I've got a noise like a thump over bumps driving me crazy and narrowed it down to the sway bar end links and have all the parts. Doing the front first. My question is there were washers between the link and frame. Should I replace them or does it really need them? All the videos I've seen never saw anyone using them and the MOOG brand I bought didn't come with any? Any thoughts on this and would the washers cause them to lossen up which has been a problem even torqued to 150ft lbs!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Washer needed?

- Thread starter Stuntmanmike1977

- Start date

TequilaWarrior

Member

I did exactly this... I sandwiched the mounts with grade 8 washers. Luckily my local hardware store has an amazing assortment. None of my replacements included the washers and I don't believe they're installed from the factory. So if you have washers on already, they aren't original. I've had real problems keeping front-end links from making noise and the washers (installed during my last link replacement) was the cure. Keep in mind that torquing to spec is an absolute MUST, even with the washers. I also installed an additional nut and gave it a little "oomph" as a jam-nut to prevent the link's included nut from backing out (which is the problem I was originally trying to solve). I am NOT doing that job again as I ended up having to cut half of the nuts off with a gd sawzall.

Also - if you're trying to fix a rattle or clunk, especially one that occurs going over bumps, remember to replace the sway bar bushings. A super simple way to diagnose the bushings is to try to bounce the bar... any "wiggle" is too much. The bushings are cheap and very easy to replace. I think I bought urethane bushings and lubed them (with silicone or whatever the directions said) to prevent "squeaks". Also, I cleaned the bushing area of the sway bar with brake cleaner thoroughly before reinstalling the bushings. Be careful not to drop the bar on yourself....

There are 2 sizes of sway bar - make sure you get the right one. I don't recall if it's stamped on the bar. I borrowed a large caliper from work to measure mine to ensure I got the right one. Honestly, the bushings are cheap enough that you could always buy both sizes and return (or not) the wrong ones.

Also - if you're trying to fix a rattle or clunk, especially one that occurs going over bumps, remember to replace the sway bar bushings. A super simple way to diagnose the bushings is to try to bounce the bar... any "wiggle" is too much. The bushings are cheap and very easy to replace. I think I bought urethane bushings and lubed them (with silicone or whatever the directions said) to prevent "squeaks". Also, I cleaned the bushing area of the sway bar with brake cleaner thoroughly before reinstalling the bushings. Be careful not to drop the bar on yourself....

There are 2 sizes of sway bar - make sure you get the right one. I don't recall if it's stamped on the bar. I borrowed a large caliper from work to measure mine to ensure I got the right one. Honestly, the bushings are cheap enough that you could always buy both sizes and return (or not) the wrong ones.

Mooseman

Moderator

I had a helluva time on my 02 with them. They kept looseming and ovaling the holes. I added two hardened washers on each stud, red Loctite and overtorqued them. Only then they stayed put.

MD_Envoy_Driver

Member

So. Guudentight?I had a helluva time on my 02 with them. They kept looseming and ovaling the holes. I added two hardened washers on each stud, red Loctite and overtorqued them. Only then they stayed put.

TequilaWarrior

Member

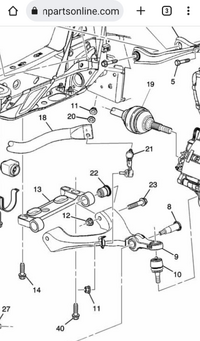

Ah.... so Part #20 in the diagram IS factory... didn't know that. However(and this will sound a tad weird), there is no washer on the GM Genuine part you posted. Well, there is, but there isn't. The base of the stud has to have a "stop".... on this part they press on a washer, but it's meant to be permanent. It's also on the link side. The washer in the diagram is on the nut side of the stabilizer bar. In the part photo, there are staked washers attached to the locknuts, possibly eliminating the need for #20. There's some margin for misinterpretation here. I can see where a tech would just toss out the washers and run the new nuts home and send it.... right or wrong.Mine had a washer or two though I cannot remember where they were. This shows just one washer and I can't imagine doing anything where it is located.

View attachment 106985

Edit: This GM unit looks like a washer-like part is built into it.

View attachment 106986

So the "where" (from the factory) is on the nut side of the stabilizer bar. The "what" has to do with how the stabilizer bar is manufactured. The end of it is "smooshed" in a press, not machined. In fact, it looks like it's forged, to me. It's not very flat, and it's not very consistent. The washer makes up for this, allowing the manufacturer a heck of a lot of wiggle room on specs for the end of the stabilizer bar.

There's some margin for misinterpretation here. I can see where a tech would just toss out the washers and run the new nuts home

The whole thing seems to be prone to trouble. I have had some replacements where the stud was a loose fit in both the stabilizer bar and the attachment to the LCA as well. NO amount of torque is going to stop this from coming loose and then wearing the hole even larger.

Having metalworking experience I ended up wrapping the stud with a thin copper strip until it filled the enlarged hole and stopped the movement of the stud in the hole, then torqued it down good.

TequilaWarrior

Member

It's a crap design, for sure. I'm a big advocate of the older design, that of 2 bushings sandwiching the mount. Specs didn't matter; it was all in the urethane bushings. If you needed longer or shorter links due to a lift or lower, just source the appropriate threaded rod (hardened, of course) and cut to length. Voila... custom length end-links. Heck, there's even rapid-disconnect end-links available for Jeeps that would not be possible without the "sandwiched bushing" end-link design. Had I a welder handy when I installed my links by sandwiching grade 8 washers, I'd have welded them in place....The whole thing seems to be prone to trouble. I have had some replacements where the stud was a loose fit in both the stabilizer bar and the attachment to the LCA as well. NO amount of torque is going to stop this from coming loose and then wearing the hole even larger.

Having metalworking experience I ended up wrapping the stud with a thin copper strip until it filled the enlarged hole and stopped the movement of the stud in the hole, then torqued it down good.

Mooseman

Moderator

For sure. So much so that GM went back to that design for 08-09.It's a crap design, for sure. I'm a big advocate of the older design, that of 2 bushings sandwiching the mount.

My bar was so egged out that I had to weld filler into it and re-drill the hole. Even then, I still put two washers and overtorqued it.

A lot of info on this, thanks everyone. I think I'll go with a hardened washer on each side so everything has a nice flat surface. Probably don't need one on the nut side because the nuts are flanged anyway. Also, is it ok to let the suspension hang freely or while on jackstands jack up the control arms a bit closer to ride height or does that matter?

Mooseman

Moderator

That's fine and may be necessary as sometimes you need to jack up one side a bit to get them aligned into the holes.Also, is it ok to let the suspension hang freely or while on jackstands jack up the control arms a bit closer to ride height or does that matter?

TequilaWarrior

Member

You likely won't have any issues getting things to line up as long as both sides are in the same state... by that I mean, either both sides are on jack stands or both sides are on ramps or both sides are on the ground. As long as there is no "twist" in the stabilizer bar, you should have no issues getting things to line up. There's also no "adjustment" for the stabilizer bar. It's not like an alignment that you can get out of whack if you don't have angles right or if you install something unloaded vs loaded.A lot of info on this, thanks everyone. I think I'll go with a hardened washer on each side so everything has a nice flat surface. Probably don't need one on the nut side because the nuts are flanged anyway. Also, is it ok to let the suspension hang freely or while on jackstands jack up the control arms a bit closer to ride height or does that matter?

As for washers on the nut side - your new nuts (adolescent giggle) may be flanged, but adding a washer will help take up some of the irregularities in the track bar.

Just put them in today with the bushings. No more noise and the suspension is stiffer. I used a breaker bar to tighten down the link nuts. Can any problems occur from over tightening them? I don't know what the torque specs are for the link nuts or the bushing bracket bolts which I know are all over torqued.

They look ok to me the way the grease fittings are placed. Only thing is I can move the pass one side to side by hand with good resistance the driver side I could not move at all by hand, had to use a large screwdriver to move it. Rode a little funny so maybe way too tight? Idk.View attachment 107431View attachment 107432

TequilaWarrior

Member

Mooseman

Moderator

Overtorquing them is fine and won't affect functionality. In fact, it's better to prevent loosening and ovalling of the holes.

far eastan

Member

No matter where I read, everything will be a valuable material.

I was worried that the stabilizer link that I replaced last year was "always loosening".

Even if I apply "Lockite" and tighten it stronger than the specified torque, it will loosen again.

At present, looseness is gone because of the winter, and the snow melting agent did a good job.

I didn't know that it would be an OVAL hole.

I decided to replace it again because the rust was fixed "with a loose nut".

However, there are things I am worried about.

It is described in the GM manual.

IMPORTANT: There is a washer between the stabilizer shaft link and the lower control arm made of hardened steel and has a felt inner liner.

Only replace this washer with an identical washer.

Standard washers should not be used.

GM 11518404, etc., is no longer stock.

Maybe this may not be loose.

I was worried that the stabilizer link that I replaced last year was "always loosening".

Even if I apply "Lockite" and tighten it stronger than the specified torque, it will loosen again.

At present, looseness is gone because of the winter, and the snow melting agent did a good job.

I didn't know that it would be an OVAL hole.

I decided to replace it again because the rust was fixed "with a loose nut".

However, there are things I am worried about.

It is described in the GM manual.

IMPORTANT: There is a washer between the stabilizer shaft link and the lower control arm made of hardened steel and has a felt inner liner.

Only replace this washer with an identical washer.

Standard washers should not be used.

GM 11518404, etc., is no longer stock.

Maybe this may not be loose.

Mooseman

Moderator

The original link had a washer but a lot of the aftermarket ones don't have or need one. I'm pretty sure the ACDelco have this washer.