2003 GMC Envoy XL 4.2L I6 278,000 miles

Greetings all! I have been long awaiting the opportunity to replace my leaking valve cover gaskets, and yesterday presented such an opportunity. Continuing the job today, I finally removed the valve cover. However, when removing the intake manifold to access the valve cover bolts, I saw my intake ports coated with the ever so popular black "mung". This should have been a clue.

I did anticipate this to an extent, as the vehicle went many years (8 years, it's been in my possession for 9 years) without proper maintenance of the CV system. That being said, it did always receive oil changes every 3,000 - 5,000 miles with synthetic blend oil for the first 5 years I owned it, then for the past 4 years full synthetic. Recently, after reading the post from Raviolli surfer about how to service the CV system, I sprayed B12 Chemtool in the orifice on the intake manifold that connects to the cylinder head, and I have been able to verify vacuum from the nipple on the valve cover that connects to the resonator box on top of the motor, while it idles. This was done many months ago, and was overdue to perform again.

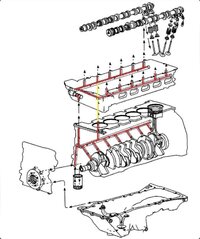

All this being said, fast forward to now, the valve cover removed, and man. I am...concerned about the amount of disgusting black coffee grounds and...dark colored...everything? Take a look:

To be honest I'm not sure what I was expecting...I should've guessed this was lurking underneath there. 278,000 miles and 21 years.

So with all this in mind, my question is. Do I go about trying to even clean any of this? I feel like a thorough clean would require complete disassembly and removal of the head, then taking it to a machine shop. Not really interested in doing that at this point if I don't have to. Will I be alright to simply, clean my intake ports, clean gasket sealing surfaces, replace gaskets, do a couple oil changes, and be on my way?

Greetings all! I have been long awaiting the opportunity to replace my leaking valve cover gaskets, and yesterday presented such an opportunity. Continuing the job today, I finally removed the valve cover. However, when removing the intake manifold to access the valve cover bolts, I saw my intake ports coated with the ever so popular black "mung". This should have been a clue.

I did anticipate this to an extent, as the vehicle went many years (8 years, it's been in my possession for 9 years) without proper maintenance of the CV system. That being said, it did always receive oil changes every 3,000 - 5,000 miles with synthetic blend oil for the first 5 years I owned it, then for the past 4 years full synthetic. Recently, after reading the post from Raviolli surfer about how to service the CV system, I sprayed B12 Chemtool in the orifice on the intake manifold that connects to the cylinder head, and I have been able to verify vacuum from the nipple on the valve cover that connects to the resonator box on top of the motor, while it idles. This was done many months ago, and was overdue to perform again.

All this being said, fast forward to now, the valve cover removed, and man. I am...concerned about the amount of disgusting black coffee grounds and...dark colored...everything? Take a look:

To be honest I'm not sure what I was expecting...I should've guessed this was lurking underneath there. 278,000 miles and 21 years.

So with all this in mind, my question is. Do I go about trying to even clean any of this? I feel like a thorough clean would require complete disassembly and removal of the head, then taking it to a machine shop. Not really interested in doing that at this point if I don't have to. Will I be alright to simply, clean my intake ports, clean gasket sealing surfaces, replace gaskets, do a couple oil changes, and be on my way?