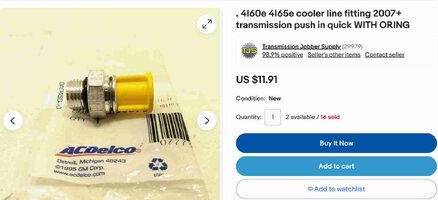

I'm installing a rebuilt transmission to my '05 trailblazer powertrain, and I had to move the transmission line connectors / quick connectors from the old transmission to the new one. Found a torque spec online of 28 ft-lbs, and managed to immediately twist the head off one connector with the torque wrench. Crap. Found an extractor that fit the stub though and the broken connector came right out. I have new ones coming from Napa in the morning, and would prefer _not_ to twist the heads off or use the gutentite protocol

does anyone know the correct spec for torquing these transmission line connectors?

does anyone know the correct spec for torquing these transmission line connectors?