Summary: Repairing steering wheel clockspring

Difficulty: 5 out of 10 for detailed electronic work

Estimated Time: 3-5 hours

Part Numbers: varies by number of steering wheel features (mine was 26086702, other reports mention 26090357)

Cost: Zero

I hope NOBODY needs to do this EVER, but I was both curious and cheap, so I spent five hours fixing a broken clockspring to save $180. Pretty good hourly rate. But I was a dumb butt for breaking it in the first place by accidentally spinning my steering wheel while it was disconnected from the rack. After three rotations, the flex cable assemblies shear off and the airbag and steering wheel buttons are dead.

Some folks might find the pics useful for doing other things inside the steering column, though.

Taking out the airbag. Two holes to press a pin punch into. Disconnect battery FIRST!!!!!

Airbag down:

Removing locking plastic clips from airbag connectors.

Pinch connectors and remove

Turn horn wiring spring post 90 degrees and remove

Remove 21 mm nut

Pull on wheel and wiggle. It might come off with no need for a puller.

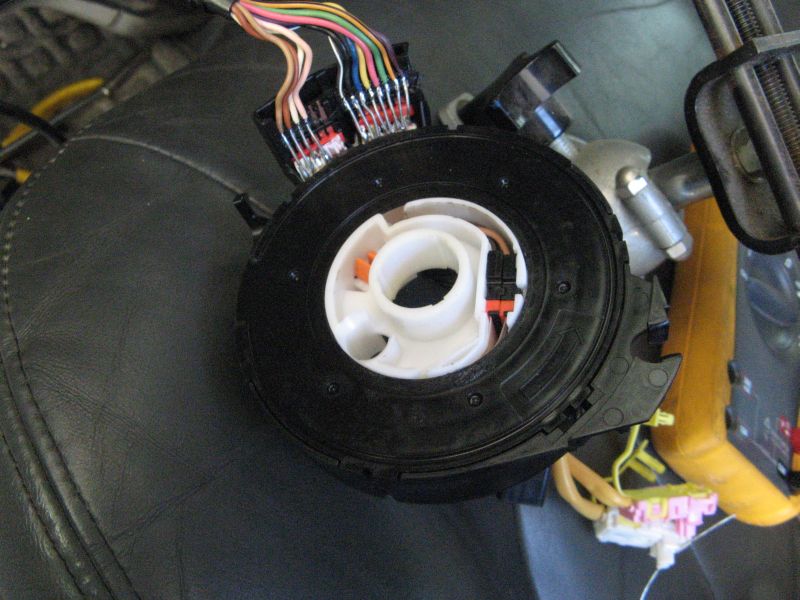

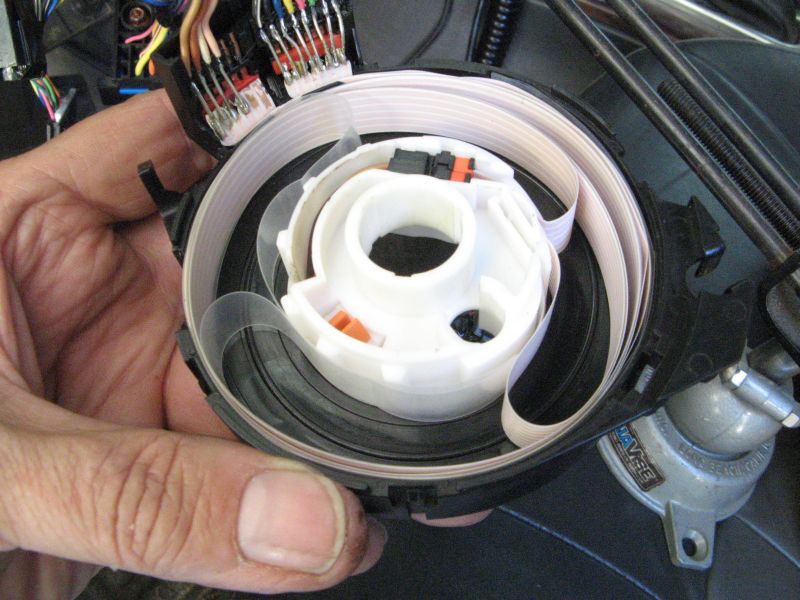

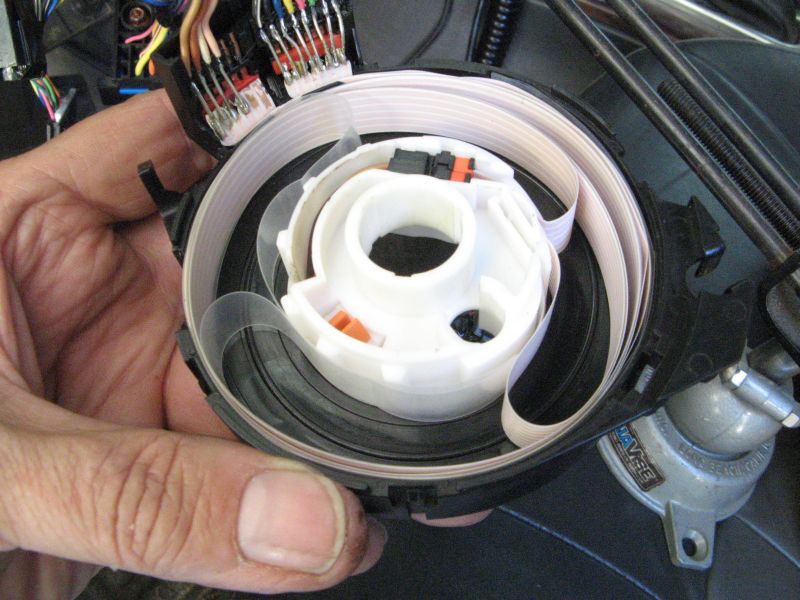

Clockspring

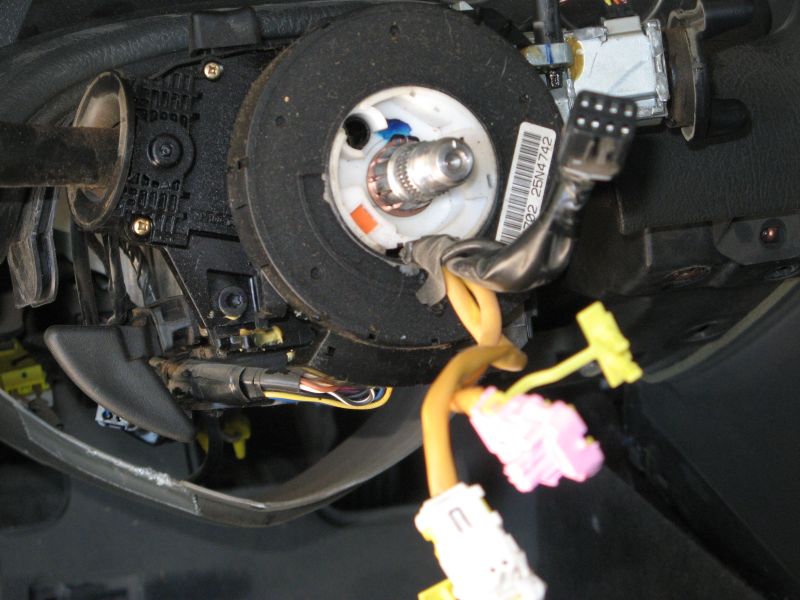

Circlip holding it on

Snap ring pliers in use

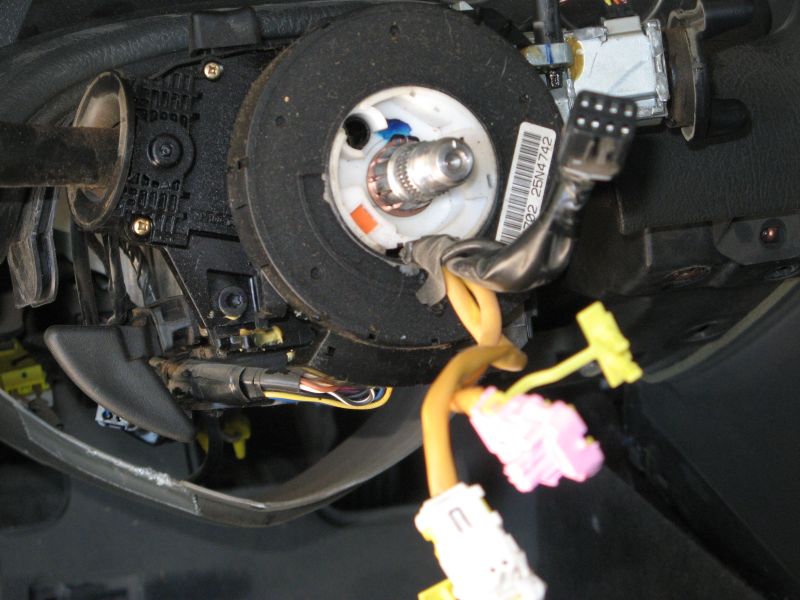

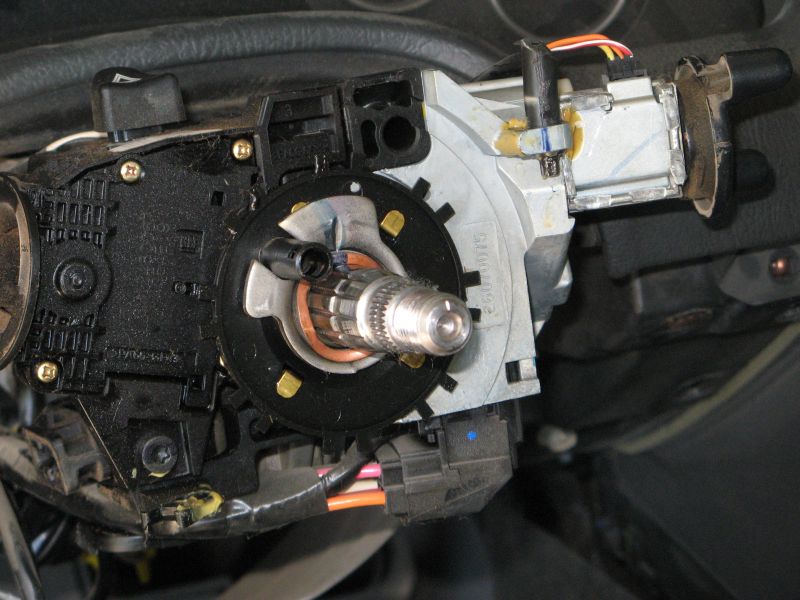

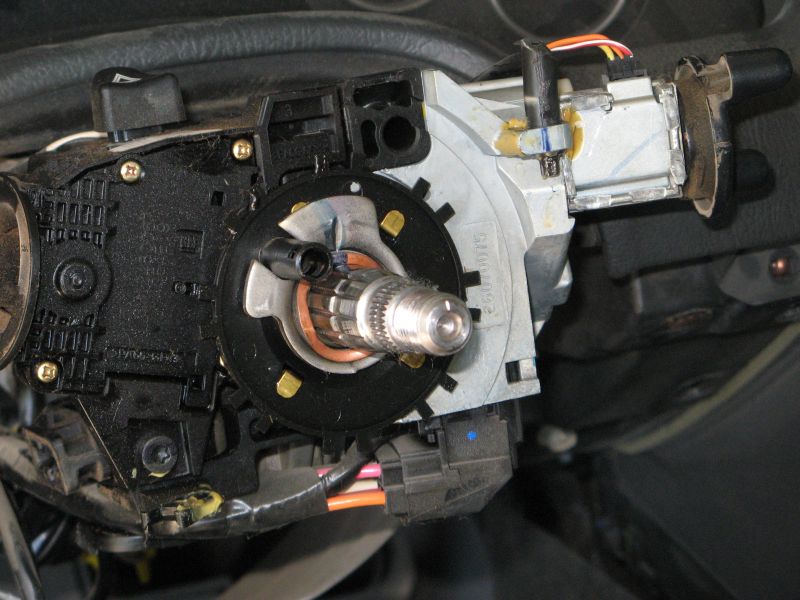

Shaft without clockspring assy.

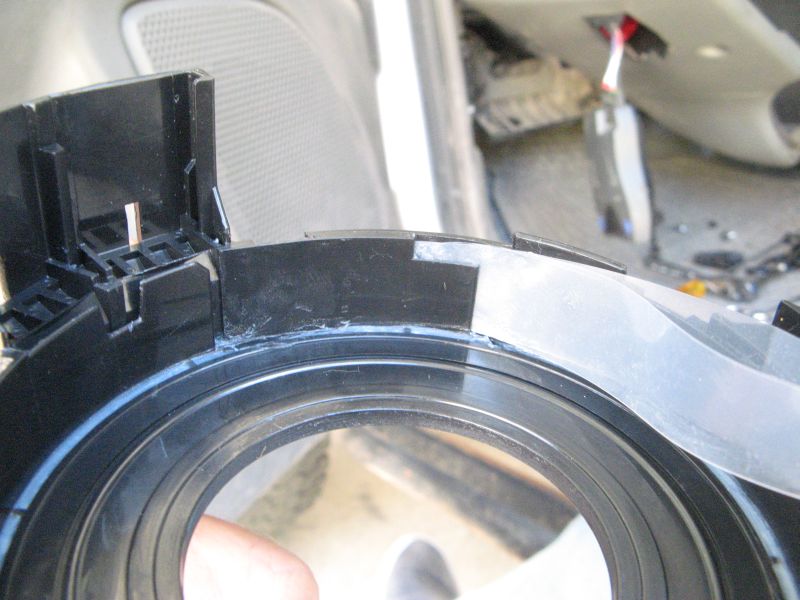

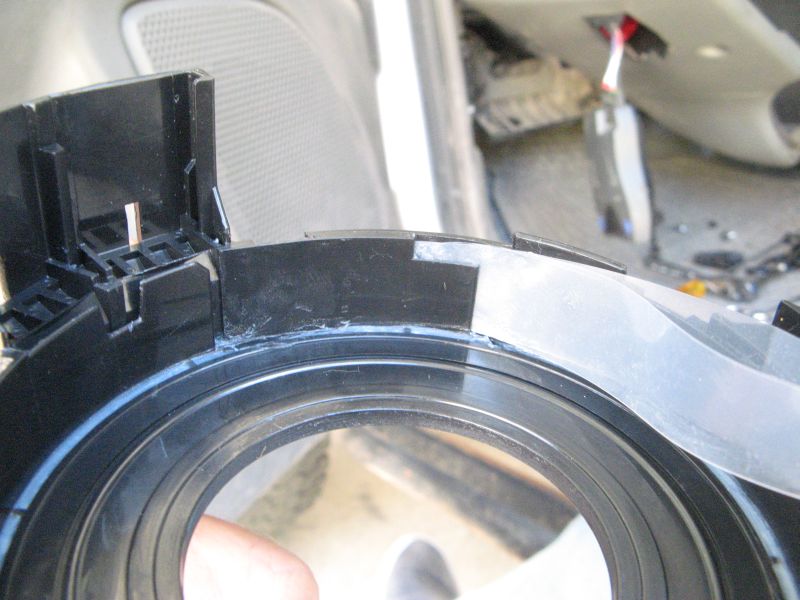

Removing clockspring cover

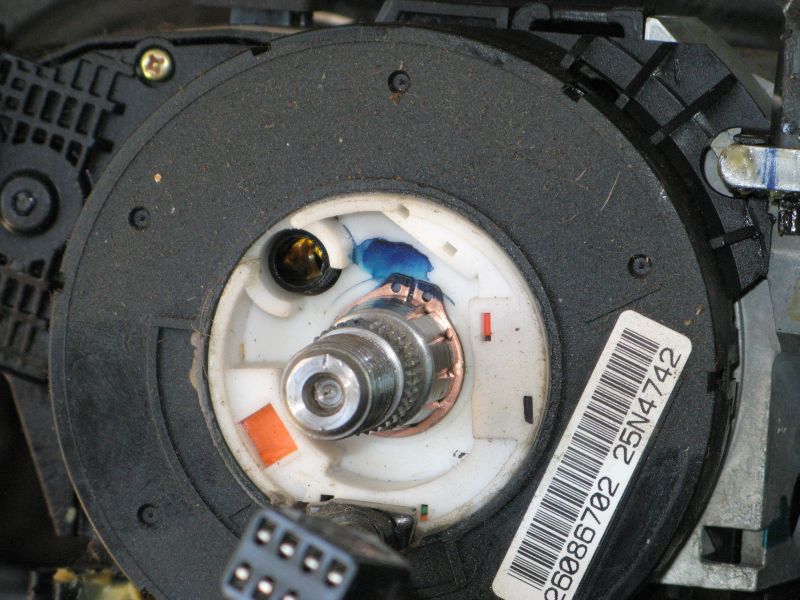

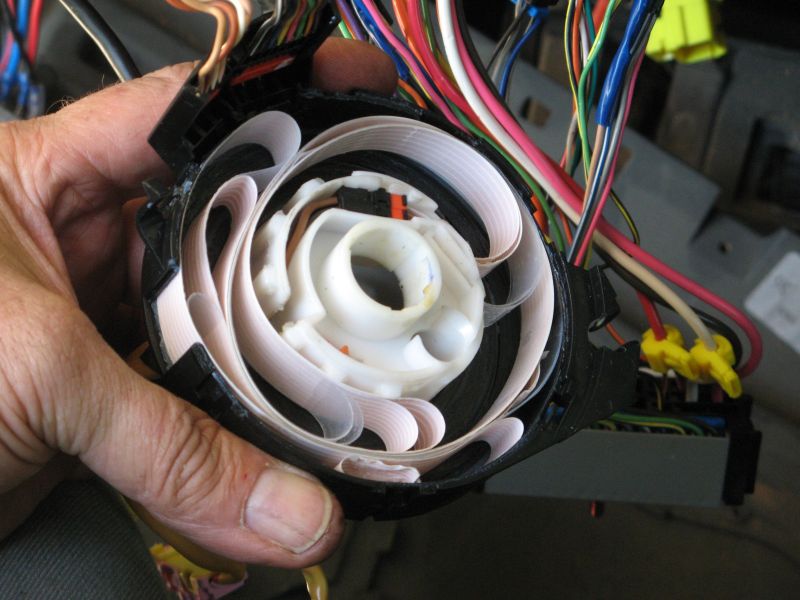

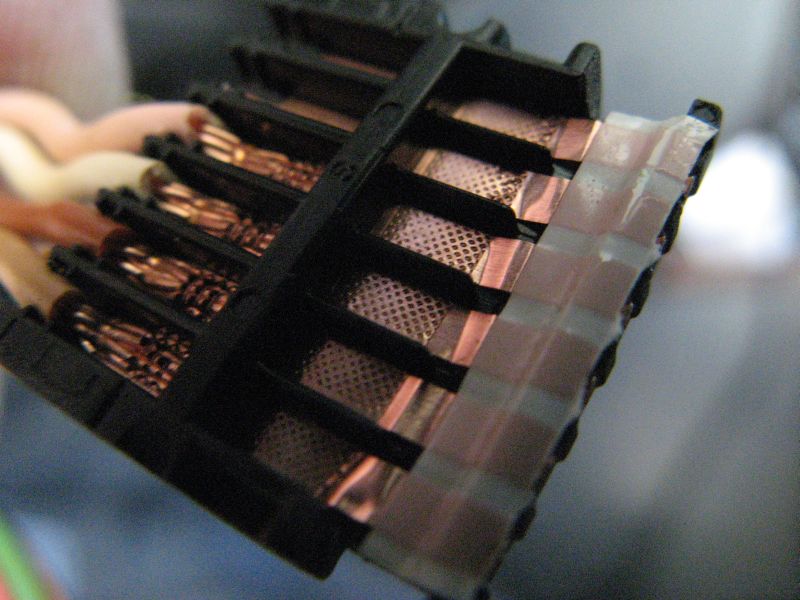

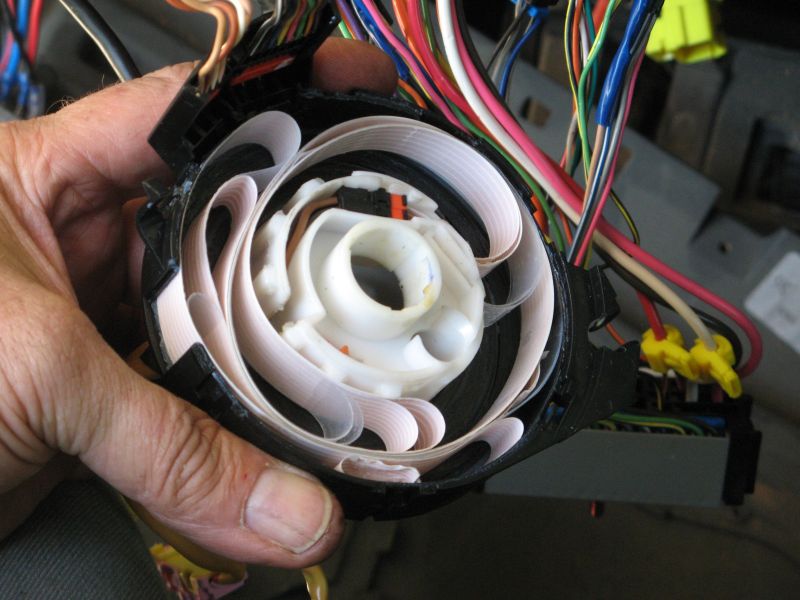

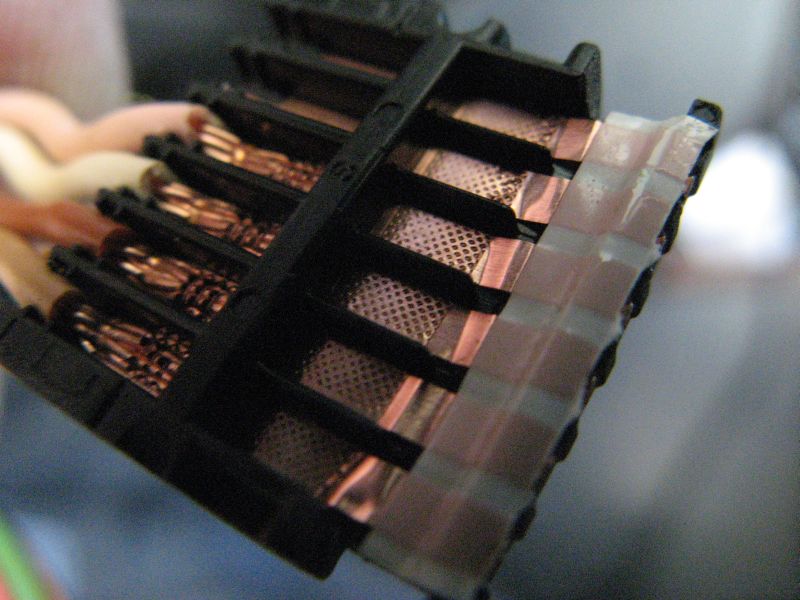

Busted guts

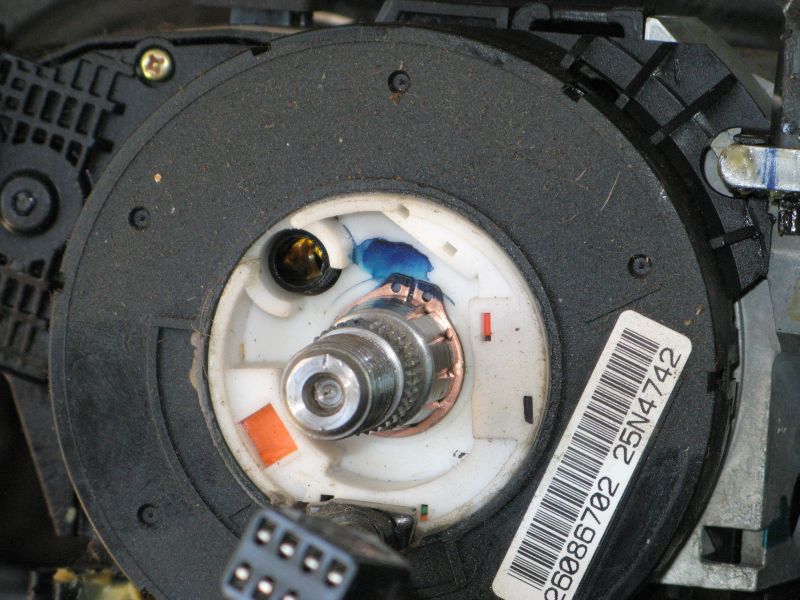

Broken off end of flex cable

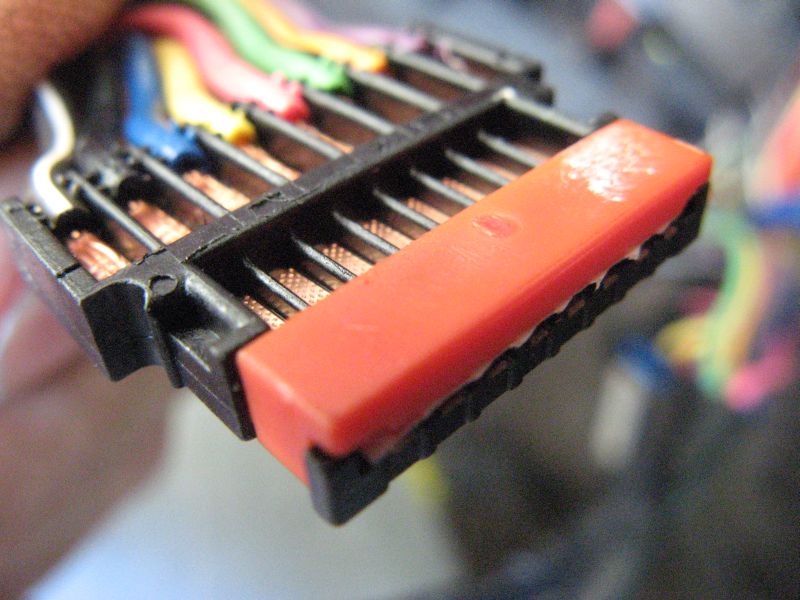

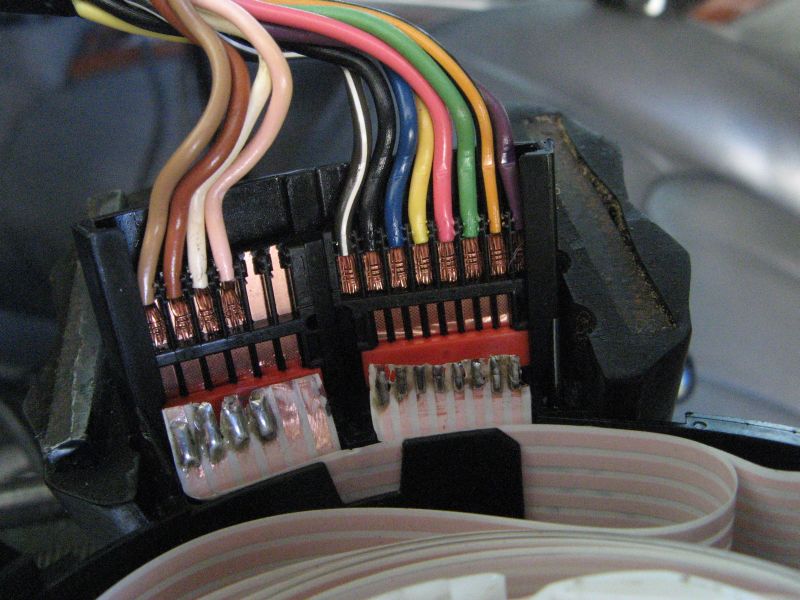

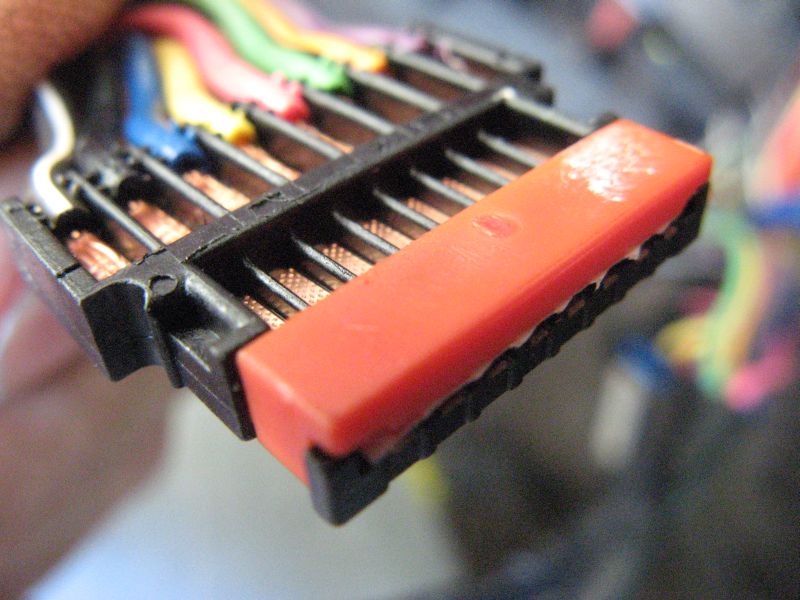

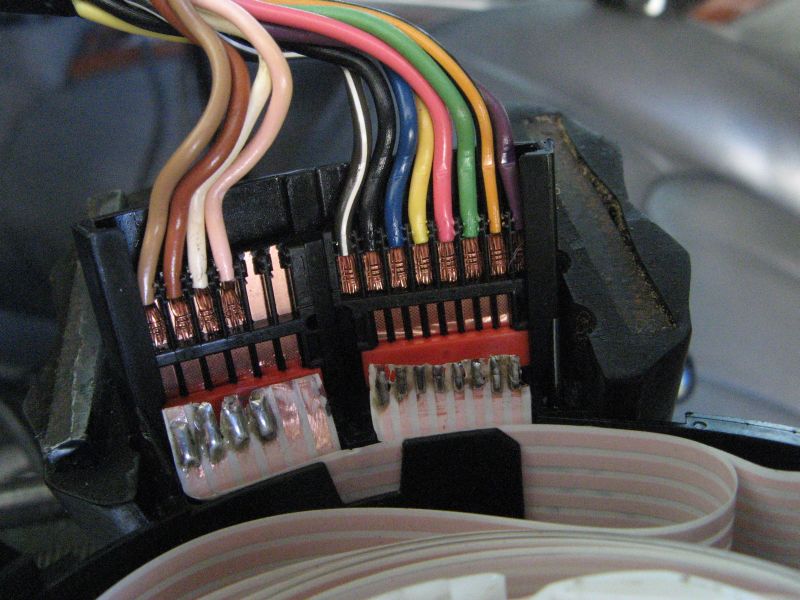

Vehicle end connectors. 6 pin one for airbag, 8 pin for steering wheel buttons

Sheared off connector end

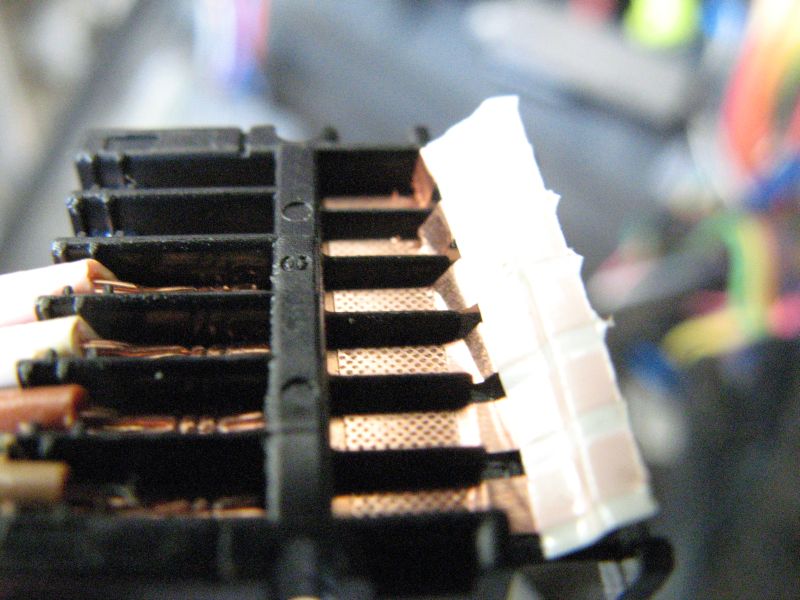

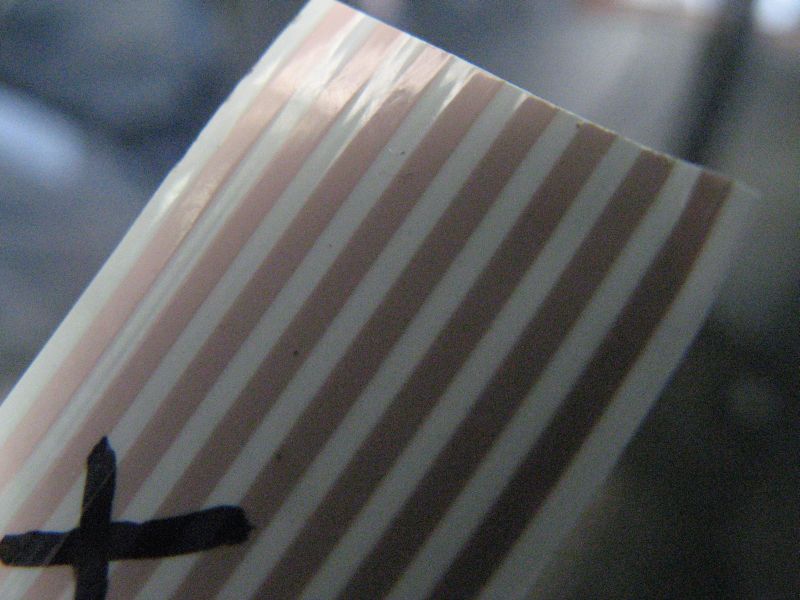

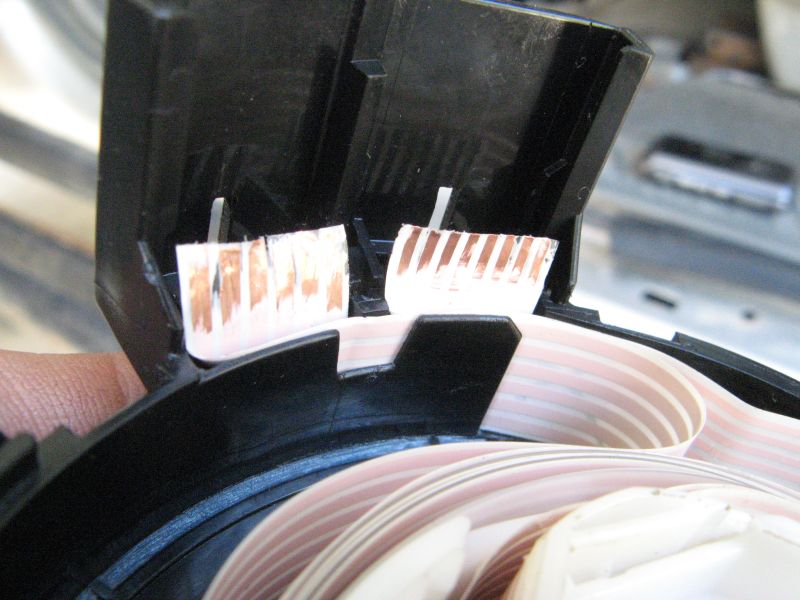

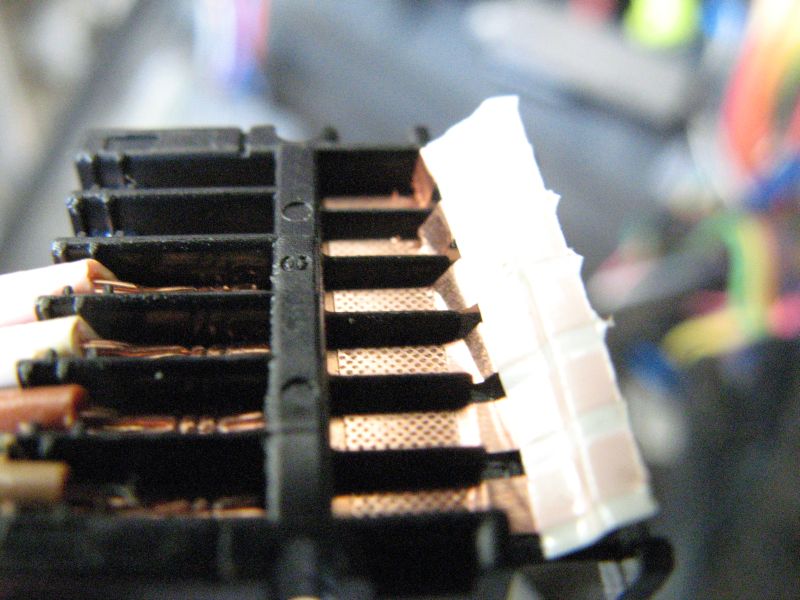

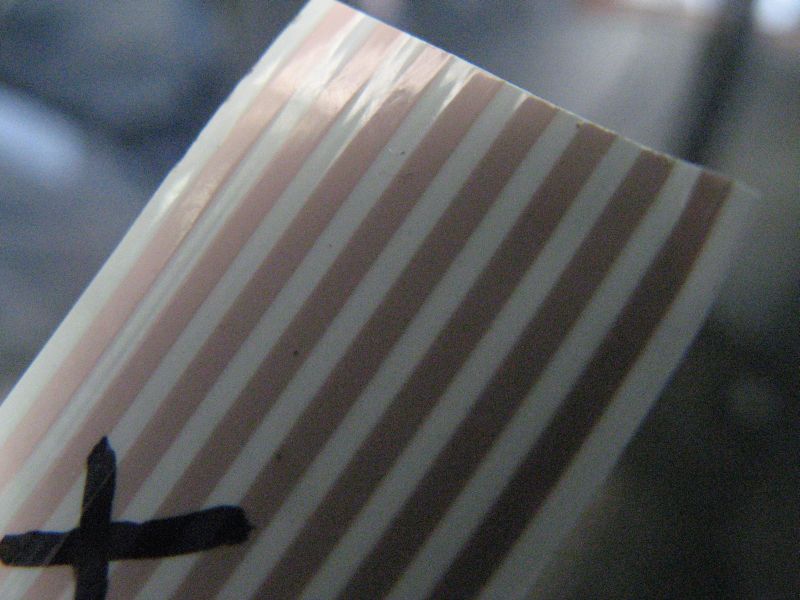

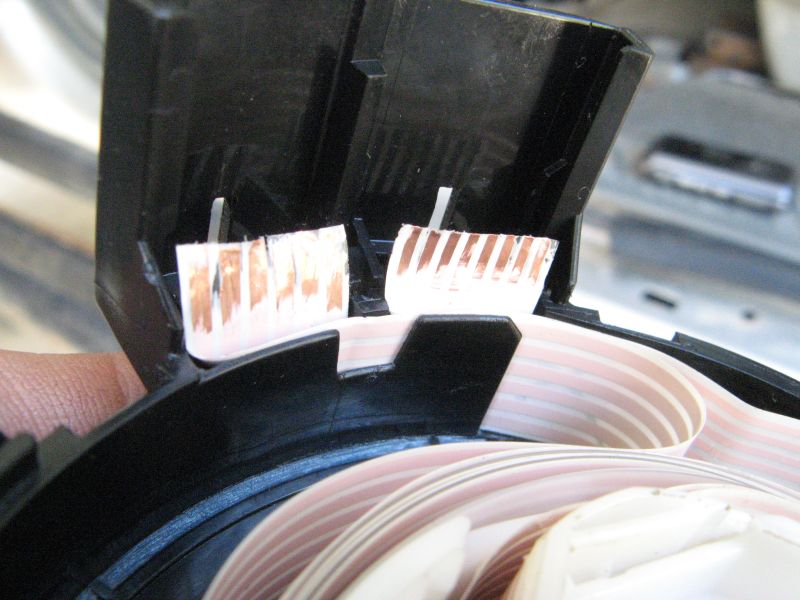

Flex cable under retention clip, showing cold ultrasonic weld connection

More detail

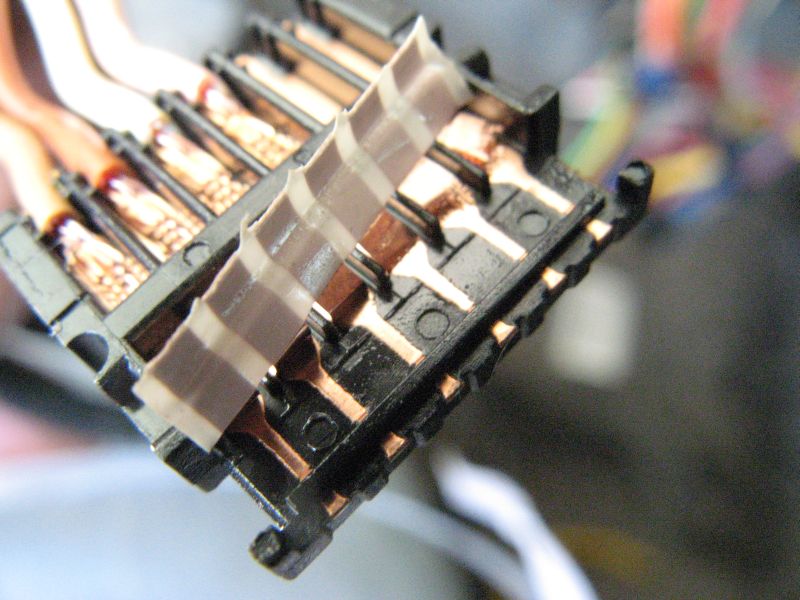

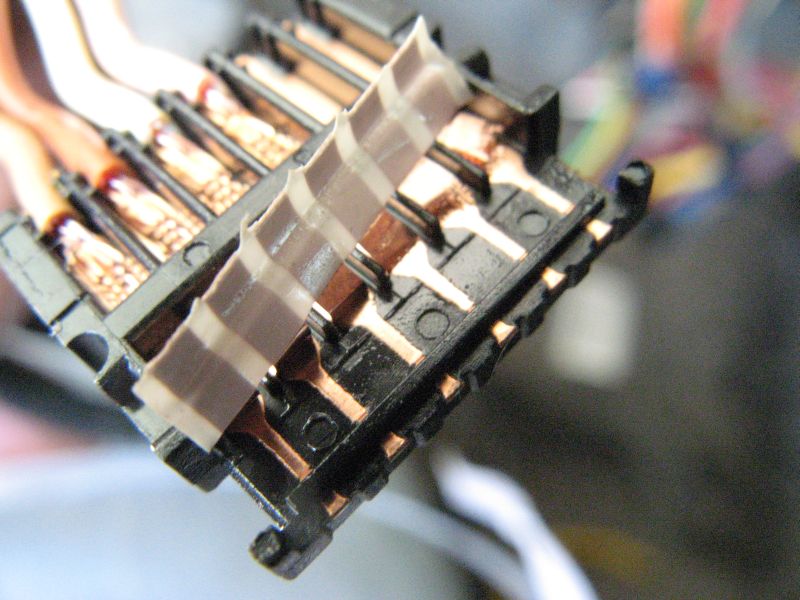

Closeup of weld

Cut off damaged part - new flex cable end

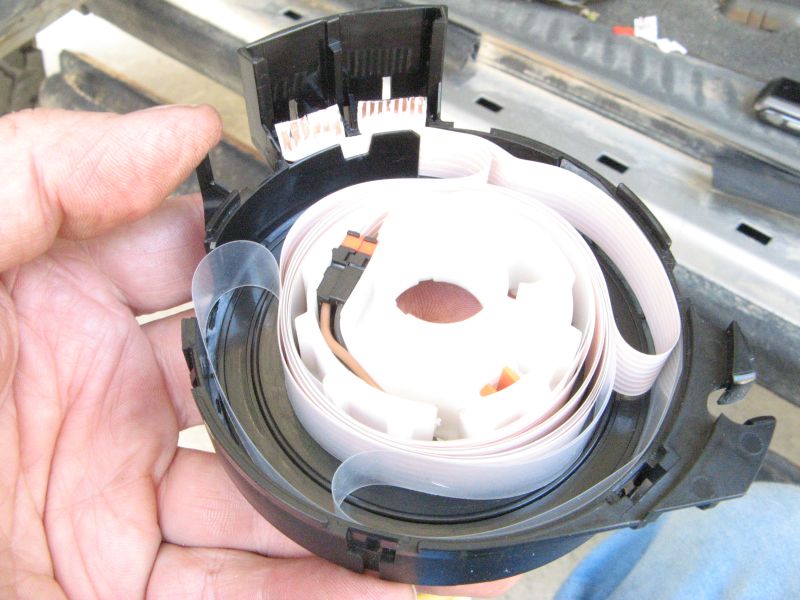

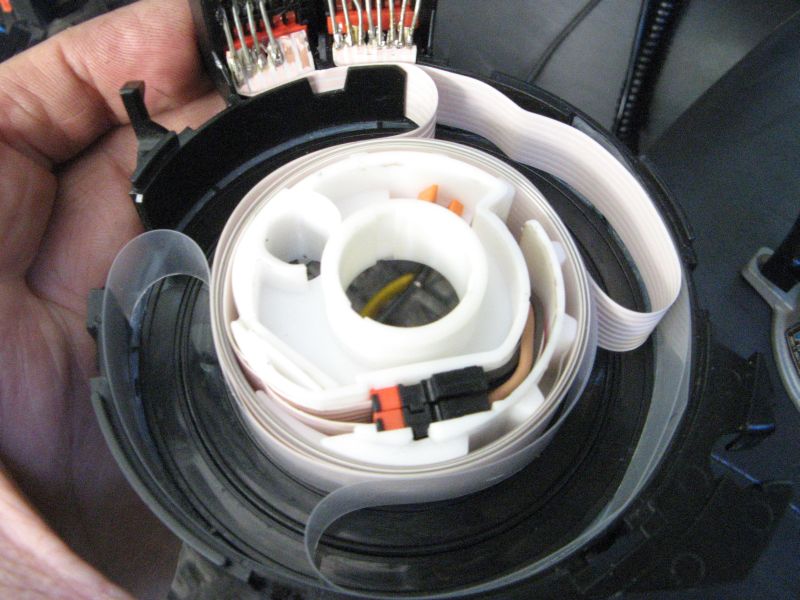

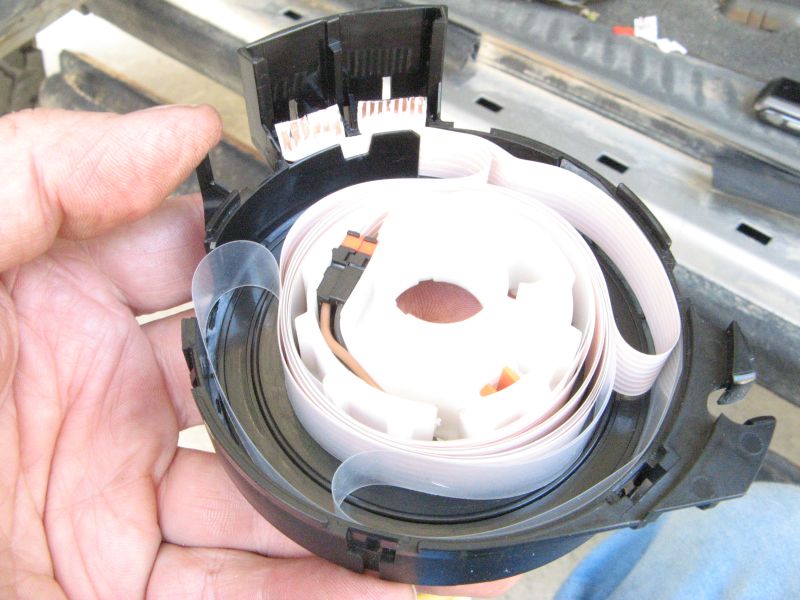

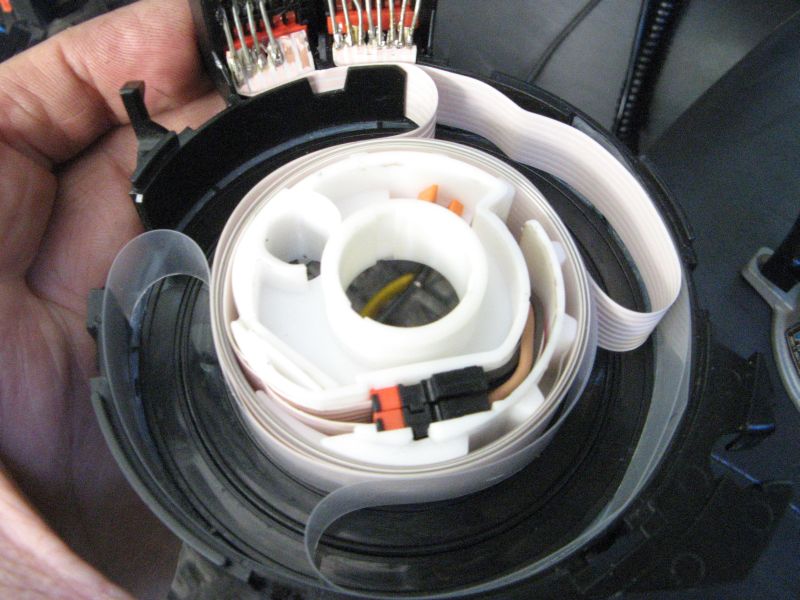

Besides the two flex cables, there is a flat nylon ribbon for cable guidance and slipperiness in the spool. It has its own slot to fit in.

Cables and ribbon arranged in the spool, ready to be reconnected.

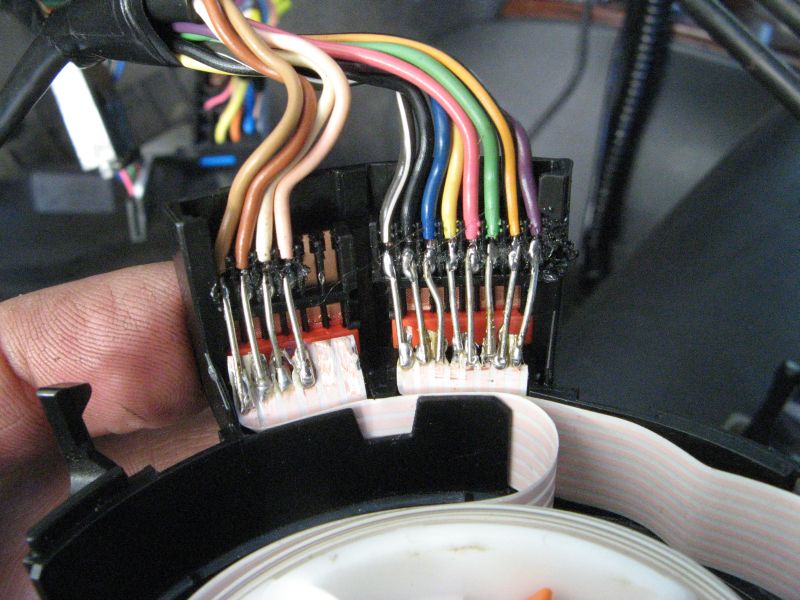

End of cables prepared by using Dremel with sandpaper flapwheel to remove plastic coating but leave the copper conductors.

Conductors tinned and connectors prepared and arranged nearby. Flex cable substrate is extremely sensitive to heat - have to solder quickly and get off .

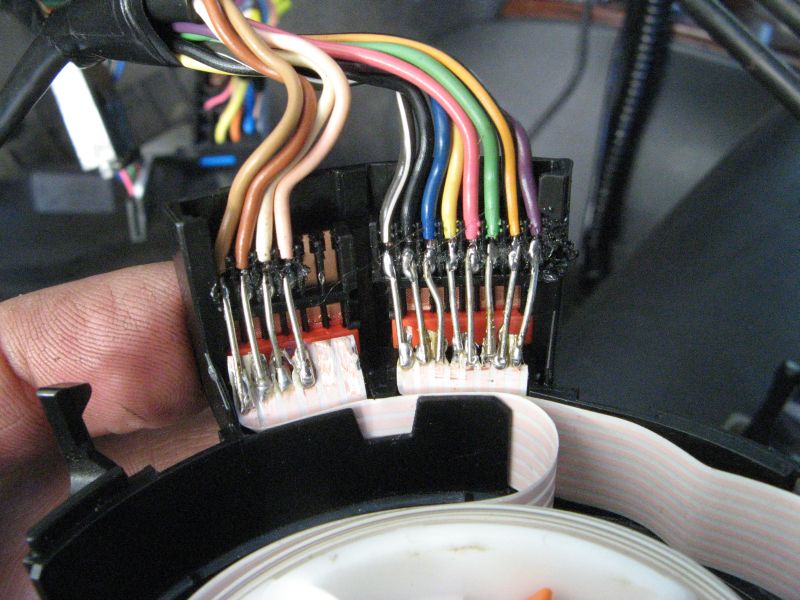

Jump wires added. Whew. This was the crappy part. Needed my magnifying binocular hood.

Full CCW test

Full CW test

Full CCW to CW is six 360 degree rotations. Three each way from centered. Rack and pinion steering gear required only TWO rotations each way from centered.

Difficulty: 5 out of 10 for detailed electronic work

Estimated Time: 3-5 hours

Part Numbers: varies by number of steering wheel features (mine was 26086702, other reports mention 26090357)

Cost: Zero

I hope NOBODY needs to do this EVER, but I was both curious and cheap, so I spent five hours fixing a broken clockspring to save $180. Pretty good hourly rate. But I was a dumb butt for breaking it in the first place by accidentally spinning my steering wheel while it was disconnected from the rack. After three rotations, the flex cable assemblies shear off and the airbag and steering wheel buttons are dead.

Some folks might find the pics useful for doing other things inside the steering column, though.

Taking out the airbag. Two holes to press a pin punch into. Disconnect battery FIRST!!!!!

Airbag down:

Removing locking plastic clips from airbag connectors.

Pinch connectors and remove

Turn horn wiring spring post 90 degrees and remove

Remove 21 mm nut

Pull on wheel and wiggle. It might come off with no need for a puller.

Clockspring

Circlip holding it on

Snap ring pliers in use

Shaft without clockspring assy.

Removing clockspring cover

Busted guts

Broken off end of flex cable

Vehicle end connectors. 6 pin one for airbag, 8 pin for steering wheel buttons

Sheared off connector end

Flex cable under retention clip, showing cold ultrasonic weld connection

More detail

Closeup of weld

Cut off damaged part - new flex cable end

Besides the two flex cables, there is a flat nylon ribbon for cable guidance and slipperiness in the spool. It has its own slot to fit in.

Cables and ribbon arranged in the spool, ready to be reconnected.

End of cables prepared by using Dremel with sandpaper flapwheel to remove plastic coating but leave the copper conductors.

Conductors tinned and connectors prepared and arranged nearby. Flex cable substrate is extremely sensitive to heat - have to solder quickly and get off .

Jump wires added. Whew. This was the crappy part. Needed my magnifying binocular hood.

Full CCW test

Full CW test

Full CCW to CW is six 360 degree rotations. Three each way from centered. Rack and pinion steering gear required only TWO rotations each way from centered.