shaun4282

Member

- Joined

- Jul 5, 2012

- Posts

- 8

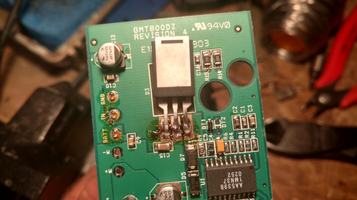

First time poster on the new site, have to say that it is alot more user friendly than TV! I am having the same issue as mentioned above with my blower motor running after truck was shut off. I'm not too confident with wiring and am nervous that I will do it wrong and short something else out. Form what I am understanding is that the new resistor has to be spliced with the old wiring system. Does anyone have a pic of what the wiring will look like with the new blower motor resistor?

Many thank in advance! This site (and as much as I hate to admit TV ) have saved me TONS!!!!

) have saved me TONS!!!!

Many thank in advance! This site (and as much as I hate to admit TV

) have saved me TONS!!!!

) have saved me TONS!!!!

).

). Parts store clerks think they're mechanics, and in reality, if they were competent, they'd ALREADY be working as mechanics. Or diagnosticians.

Parts store clerks think they're mechanics, and in reality, if they were competent, they'd ALREADY be working as mechanics. Or diagnosticians.

Solder suckers were all the rage, but the mechanical shock was starting to damage a lot of parts, even if you had the ESD-safe conductive barrel units. Desolder wick is an absolutely critical tool for surface mount parts. Solder suckers are still good for through hole items like stepper motors.

Solder suckers were all the rage, but the mechanical shock was starting to damage a lot of parts, even if you had the ESD-safe conductive barrel units. Desolder wick is an absolutely critical tool for surface mount parts. Solder suckers are still good for through hole items like stepper motors.