Hello all,

We have a 2005 TB, I6 with ~80k miles on it. Started getting a gear whine type noise in the front end. My example would be the muffled sound of putting a baseball card on the fork of your bicycle to have it flip through the spokes of the wheel as you ride... Sound is speed related, and there is a little vibration input coming through the steering wheel.

I got the front end up on jack stands and spun both front tires. Its in the driver's side. I grabbed the axle shaft between the two CV joints and there was play in it. There was none on the passenger side. I need to get back under there and grab the axle shaft side that goes into the differential to try to see if it is the inner CV, or something internal to the diff... I hope it's just the CV... No signs of grease, or a torn boot, so a little surprised the CV would go. Concerned it could be internal to the diff...

Any other diagnostic advice? I like to make sure I've got the right thing, before I start throwing parts at it...

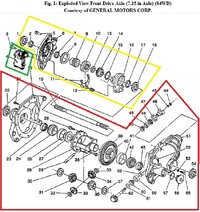

If it is the CV, my plan is to replace the whole axle shaft assembly. My searches showed the Cardone (sp?) unit runs about $40 - $60, so that's not too bad. I didn't see any "How Too" on replacing it. People replacing other parts (bearings, etc.) touched on it, but I didn't see much detail on just replacing the axle shaft assembly. It looks like the hardest part is getting it knocked out of the hub assembly, once you take the upper ball joint loose and lay the suspension assembly out so it can be pulled free. Anyone have more advice you could share?

UPDATE:

Just replaced the axle shaft, and that did nothing. Drained and replaced the differential fluid, and it looks like there is fine metal dust in it. Used a magnet, but it didn't pick anything up. It looks a little brass in color, so my guess is that's what it is... Anyone had the front different go? Anything else I can look for?

Thanks!

We have a 2005 TB, I6 with ~80k miles on it. Started getting a gear whine type noise in the front end. My example would be the muffled sound of putting a baseball card on the fork of your bicycle to have it flip through the spokes of the wheel as you ride... Sound is speed related, and there is a little vibration input coming through the steering wheel.

I got the front end up on jack stands and spun both front tires. Its in the driver's side. I grabbed the axle shaft between the two CV joints and there was play in it. There was none on the passenger side. I need to get back under there and grab the axle shaft side that goes into the differential to try to see if it is the inner CV, or something internal to the diff... I hope it's just the CV... No signs of grease, or a torn boot, so a little surprised the CV would go. Concerned it could be internal to the diff...

Any other diagnostic advice? I like to make sure I've got the right thing, before I start throwing parts at it...

If it is the CV, my plan is to replace the whole axle shaft assembly. My searches showed the Cardone (sp?) unit runs about $40 - $60, so that's not too bad. I didn't see any "How Too" on replacing it. People replacing other parts (bearings, etc.) touched on it, but I didn't see much detail on just replacing the axle shaft assembly. It looks like the hardest part is getting it knocked out of the hub assembly, once you take the upper ball joint loose and lay the suspension assembly out so it can be pulled free. Anyone have more advice you could share?

UPDATE:

Just replaced the axle shaft, and that did nothing. Drained and replaced the differential fluid, and it looks like there is fine metal dust in it. Used a magnet, but it didn't pick anything up. It looks a little brass in color, so my guess is that's what it is... Anyone had the front different go? Anything else I can look for?

Thanks!

After reading here that the disconnect is most liklely what fails, I raised the passenger side and finally got the scraping noise when turning the wheel and went ahead and removed the axle and waa laa ....bearing pieces..... hope this helps

After reading here that the disconnect is most liklely what fails, I raised the passenger side and finally got the scraping noise when turning the wheel and went ahead and removed the axle and waa laa ....bearing pieces..... hope this helps

Spent a little more time under the truck this afternoon...

Spent a little more time under the truck this afternoon...

I think there is room for a grease fitting. I am going to put one in mine

I think there is room for a grease fitting. I am going to put one in mine Could I just remove the driver side axle shaft and the front drive shaft? This would (should) isolate the diff, since the disconnect would be open and the passenger side would not be turning the intermediate shaft. That way I "should" be able to eliminate that as a cause. Then, I can narrow it down to the hub bearings or disconnect.

Could I just remove the driver side axle shaft and the front drive shaft? This would (should) isolate the diff, since the disconnect would be open and the passenger side would not be turning the intermediate shaft. That way I "should" be able to eliminate that as a cause. Then, I can narrow it down to the hub bearings or disconnect.