Hi all,

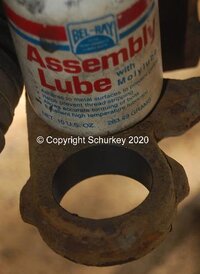

Any advice how to get this LBJ out? I have a press and already did my uppers but now that I have everything apart I see there is no snap ring.

I cannot replace the entire control arm today, so I don’t want to start grinding away or damage it if I wouldn’t be able to finish.

It appears it could be replaceable but maybe press fit into place?

Any advice how to get this LBJ out? I have a press and already did my uppers but now that I have everything apart I see there is no snap ring.

I cannot replace the entire control arm today, so I don’t want to start grinding away or damage it if I wouldn’t be able to finish.

It appears it could be replaceable but maybe press fit into place?