Hi people,

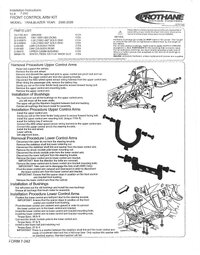

Next up for me is the bushings in the front end. Step one will be the 5 control arm bushings on each side.

I found this poly kit for the arms https://www.suspension.com/7242. I've always gone with poly in the past and it's nearly the same price as the rubber MOOG ones.

That kit doesn't include the MOOG K200270 for the bottom of the strut so I'll get those seperate.

These days I have access to a press and Autozone sells a PowerBuilt Bushing Driver Set for only $36! In the past I've used a home made tool consisting of a stick of all thread, a super heavy duty thrust bearing, peices of pipe, large sockets, and lots of washers.

Has anyone put the poly bushings in?

Putting the bushings in with a press is pretty simple, I'm not so sure about getting them out. I may have to use my home made tool for that. I don't think I've done any as big as those lower front ones though.

Next up for me is the bushings in the front end. Step one will be the 5 control arm bushings on each side.

I found this poly kit for the arms https://www.suspension.com/7242. I've always gone with poly in the past and it's nearly the same price as the rubber MOOG ones.

That kit doesn't include the MOOG K200270 for the bottom of the strut so I'll get those seperate.

These days I have access to a press and Autozone sells a PowerBuilt Bushing Driver Set for only $36! In the past I've used a home made tool consisting of a stick of all thread, a super heavy duty thrust bearing, peices of pipe, large sockets, and lots of washers.

Has anyone put the poly bushings in?

Putting the bushings in with a press is pretty simple, I'm not so sure about getting them out. I may have to use my home made tool for that. I don't think I've done any as big as those lower front ones though.