Ok I'll try to explain this the best I can as Im still learning electronics.

Im looking to power a 12V-0.12A fan AND a stepper motor driver at 12V-1.2A(Pololu - A4988 Stepper Motor Driver Carrier)

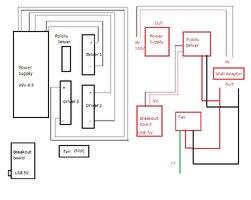

My existing setup consists of a 36V-8.8A power supply wired in parallel to three stepper motor drivers. This is for my existing 3axis CNC router setup.

Im looking to add this 4th pololu driver(link above) to retro-fit a 3d printer extruder for 3d printing.

Im trying to figure out how I would supply power for both of these components. I was thinking of buying a 12V wall adapter and either connecting it to my surge protector OR wire the wall adapter to my existing 36V power supply. (to save a plug opening on my surge protector) First Q, would wiring the adapter to the 36V power source rather than the surge protector(110V) affect the rated output?

2nd Q, after I cut the end of the adapter and separate the + and - wire, how would I wire the rest? Both the fan and driver will be receiving their required 12 volts, Im just unsure about how to wire it up so the fan receives its 0.12A and the driver its 1.2A. Would I have to split two + and two - wires from the end of the wall adapter(parallel) and just add the two different required resistors needed for both components? Or am I totally off? Any help would be much appreciated.

Hope I explained it well enough without any visuals but if it makes it easier I can sketch up a quick diagram of my setup.

NOTE: the motor this pololu driver will be driving is rated at 6.5V-1.2A(http://store.qu-bd.com/product.php?id_product=14)

Im looking to power a 12V-0.12A fan AND a stepper motor driver at 12V-1.2A(Pololu - A4988 Stepper Motor Driver Carrier)

My existing setup consists of a 36V-8.8A power supply wired in parallel to three stepper motor drivers. This is for my existing 3axis CNC router setup.

Im looking to add this 4th pololu driver(link above) to retro-fit a 3d printer extruder for 3d printing.

Im trying to figure out how I would supply power for both of these components. I was thinking of buying a 12V wall adapter and either connecting it to my surge protector OR wire the wall adapter to my existing 36V power supply. (to save a plug opening on my surge protector) First Q, would wiring the adapter to the 36V power source rather than the surge protector(110V) affect the rated output?

2nd Q, after I cut the end of the adapter and separate the + and - wire, how would I wire the rest? Both the fan and driver will be receiving their required 12 volts, Im just unsure about how to wire it up so the fan receives its 0.12A and the driver its 1.2A. Would I have to split two + and two - wires from the end of the wall adapter(parallel) and just add the two different required resistors needed for both components? Or am I totally off? Any help would be much appreciated.

Hope I explained it well enough without any visuals but if it makes it easier I can sketch up a quick diagram of my setup.

NOTE: the motor this pololu driver will be driving is rated at 6.5V-1.2A(http://store.qu-bd.com/product.php?id_product=14)

)

)