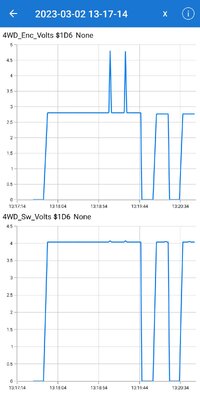

So after many years of occasional issues with the transfer case shift motor encoder I decide to fix the damn thing. Hooked up the Tech 2 to display the encoder return voltage and take it under the truck with me. Wiggle this, push pull that, tap here and there all the while watching that return voltage. Pinned it down to something internal to the motor-encoder assembly. Push sidewards on the rubber that seals the entry of the harness to the encoder motor and the return voltage swings wildly from zero to a more normal 2.something. Now without a tech 2 I suppose one could do the same task by disconnecting the encoder motor harness and use a ohm meter to observe the readings across the various encoder circuits, in my 2002 these are the green/black, brown/white, and black/white wires. (Which BTW appear to incorrectly labeled in at least 2 schematics I found online. The 5 VDC reference goes to connection C, not A, and the 0 VDC reference goes to connection A, not C. You cannot see these connections without disassembling the encoder motor anyway)

So where was I? Oh yes. Pinpointed the area of interest. Removed the fuel tank skid plate to gain better access then disconnected the harness and removed the encoder motor.

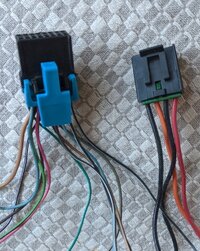

Carefully removed the insulator to reveal the encoder ring hoping I might find some poor connection therein. I did not. So pulled out the encoder ring and set about directly testing that. The original was a sealed unit so all I could do was use an ohm meter and see what could be learned. When connected to the 2 outer terminals the reading jumped about if I used a small screwdriver to exert a little force this way or that on the terminal. Well crap! Sealed unit so I order a replacement online. ACDelco #89059276.

Since a new one is on the way lets see what makes this thing tick. Turns out to be quite difficult to get apart. Destructive even! Eventually I get it open, cracking the ceramic circuit base in the process but hey,, it was already scrap. Very interesting innards. With really close inspection the fault is found to be cracked solder joint. Multiple cracks even. Seen on the ceramic base are little flags at the various positions for 2Hi, A4WD, 4Hi, etc. Nothing one can do about all this...I just find it interesting to see how things actually work.

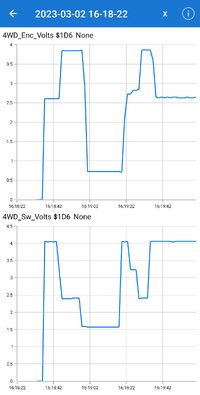

So the new part comes. Time will tell but initially disappointing. Looks cheap. Open construction instead of sealed unit leaving the seals of the insulator to keep it clean I guess. Later I discover it's a little tight on the motor shaft, if I were to install as it came out of the package it would no doubt break if one had to remove it. There are some manufactured bosses on the inner diameter and I file these to produce a workable fit. I reassemble all and install the whole business back in the truck. Everything works fine as it should. I take the Tech 2 again and live plot the encoder return and dash selector switch position return voltages and watch for fluctuations as I drive the dirt roads around the house here in the Colorado mountains, shifting to all possible selections, intentionally looking to jostle things. Looks good so far!

So where was I? Oh yes. Pinpointed the area of interest. Removed the fuel tank skid plate to gain better access then disconnected the harness and removed the encoder motor.

Carefully removed the insulator to reveal the encoder ring hoping I might find some poor connection therein. I did not. So pulled out the encoder ring and set about directly testing that. The original was a sealed unit so all I could do was use an ohm meter and see what could be learned. When connected to the 2 outer terminals the reading jumped about if I used a small screwdriver to exert a little force this way or that on the terminal. Well crap! Sealed unit so I order a replacement online. ACDelco #89059276.

Since a new one is on the way lets see what makes this thing tick. Turns out to be quite difficult to get apart. Destructive even! Eventually I get it open, cracking the ceramic circuit base in the process but hey,, it was already scrap. Very interesting innards. With really close inspection the fault is found to be cracked solder joint. Multiple cracks even. Seen on the ceramic base are little flags at the various positions for 2Hi, A4WD, 4Hi, etc. Nothing one can do about all this...I just find it interesting to see how things actually work.

So the new part comes. Time will tell but initially disappointing. Looks cheap. Open construction instead of sealed unit leaving the seals of the insulator to keep it clean I guess. Later I discover it's a little tight on the motor shaft, if I were to install as it came out of the package it would no doubt break if one had to remove it. There are some manufactured bosses on the inner diameter and I file these to produce a workable fit. I reassemble all and install the whole business back in the truck. Everything works fine as it should. I take the Tech 2 again and live plot the encoder return and dash selector switch position return voltages and watch for fluctuations as I drive the dirt roads around the house here in the Colorado mountains, shifting to all possible selections, intentionally looking to jostle things. Looks good so far!

Attachments

-

image-20190701_122823.jpg443.8 KB · Views: 38

image-20190701_122823.jpg443.8 KB · Views: 38 -

IMG_20190701_124930.jpg624.4 KB · Views: 36

IMG_20190701_124930.jpg624.4 KB · Views: 36 -

IMG_20190701_125048.jpg580.2 KB · Views: 34

IMG_20190701_125048.jpg580.2 KB · Views: 34 -

IMG_20190702_173423_HDR.jpg537.3 KB · Views: 35

IMG_20190702_173423_HDR.jpg537.3 KB · Views: 35 -

IMG_20190701_175332.jpg337.2 KB · Views: 35

IMG_20190701_175332.jpg337.2 KB · Views: 35 -

P1090052.JPG505 KB · Views: 31

P1090052.JPG505 KB · Views: 31 -

P1090063.JPG465.8 KB · Views: 32

P1090063.JPG465.8 KB · Views: 32 -

P1090061.JPG472.9 KB · Views: 29

P1090061.JPG472.9 KB · Views: 29 -

P1090068.JPG459.6 KB · Views: 31

P1090068.JPG459.6 KB · Views: 31 -

IMG_20190704_201404.jpg458.3 KB · Views: 34

IMG_20190704_201404.jpg458.3 KB · Views: 34