We've all heard the expression "Stepper Motors and LEDs" whenever problems with Instrument Panel Clusters (IPC) raise their Ugly Heads. The same thing goes for the "PRND123" Displays, too as per problems with them "Dimming" or when they inexplicably TURN OFF.

But for those of us who own Full Size GM and GMC Trucks, circa 1999-2002... These expressions will NOT apply to the IPCs nested in our Dashboards. Here are the important distinctions:

The Basics of the 1999-2002 GM Full Size Truck IPCs:

(1) Instead of employing the "Stepper Motors" ...the 99-02 Full Size Pick-Up Trucks use Durable Air Core Dash Panel Gauges that will RARELY if ever Fail. This is because their Coils and Electro-Magnetic Innards are quite Wire Wound Copper and very robust. When they DO Misbehave with having either "Bouncing or Jittery Gauges Needles" this is because these devices are filled with Thick Oil that acts as a Shock Dampener that will occasionally diminish over time and require replenishment. This can be observed about half way through this related Video...again the entire session is worth watching:

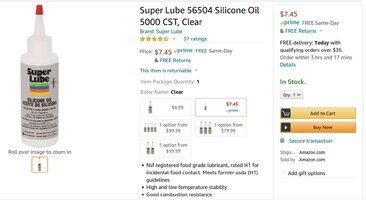

The Gauge Repair becomes possible by using a hypodermic syringe filled with 90 Weight Gear Oil or some other Oil with similarly thick viscosity. The Oil gets injected inside of the Metal Casements over the 'Needle Axles' in order to displace the Air Bubble within. These Gauges are all very expensive to replace and can run as high as $100.00 a piece, so servicing whenever possible makes better sense.

(2) Unlike the Soldered-in LEDS on the other SUVs and Later Model GM Trucks, the 99-02 GM-GMC Trucks have Replaceable Dash Panel IPC Incandescent Bulbs that obviate the need to require a Technician to remove the Needles from the IPC front panels and then have to perform the R&R Soldering Jobs of some or all of the other style Gauges in order to change them. These Bulbs are easily accessible via their Twist Sockets after removing the light plastic back cover on these Early Model IPCs.

(3) The Logic Boards of the IPCs in the 99-02 GM Trucks are VERY well made and when they fail or show any performance issues; even the most difficult problems, like a Failed or Dimming Fluorescent PRNDL123 Panel. These issues be addressed once you have a better idea of HOW these Logic Boards and their components can be Accessed and Diagnosed using a decent DVOM or DMM and actually re-soldering some of the smaller component connections back onto the Boards. THIS Video arguably has the Very BEST Description of How To Do Just THAT:

But for those of us who own Full Size GM and GMC Trucks, circa 1999-2002... These expressions will NOT apply to the IPCs nested in our Dashboards. Here are the important distinctions:

The Basics of the 1999-2002 GM Full Size Truck IPCs:

(1) Instead of employing the "Stepper Motors" ...the 99-02 Full Size Pick-Up Trucks use Durable Air Core Dash Panel Gauges that will RARELY if ever Fail. This is because their Coils and Electro-Magnetic Innards are quite Wire Wound Copper and very robust. When they DO Misbehave with having either "Bouncing or Jittery Gauges Needles" this is because these devices are filled with Thick Oil that acts as a Shock Dampener that will occasionally diminish over time and require replenishment. This can be observed about half way through this related Video...again the entire session is worth watching:

The Gauge Repair becomes possible by using a hypodermic syringe filled with 90 Weight Gear Oil or some other Oil with similarly thick viscosity. The Oil gets injected inside of the Metal Casements over the 'Needle Axles' in order to displace the Air Bubble within. These Gauges are all very expensive to replace and can run as high as $100.00 a piece, so servicing whenever possible makes better sense.

(2) Unlike the Soldered-in LEDS on the other SUVs and Later Model GM Trucks, the 99-02 GM-GMC Trucks have Replaceable Dash Panel IPC Incandescent Bulbs that obviate the need to require a Technician to remove the Needles from the IPC front panels and then have to perform the R&R Soldering Jobs of some or all of the other style Gauges in order to change them. These Bulbs are easily accessible via their Twist Sockets after removing the light plastic back cover on these Early Model IPCs.

(3) The Logic Boards of the IPCs in the 99-02 GM Trucks are VERY well made and when they fail or show any performance issues; even the most difficult problems, like a Failed or Dimming Fluorescent PRNDL123 Panel. These issues be addressed once you have a better idea of HOW these Logic Boards and their components can be Accessed and Diagnosed using a decent DVOM or DMM and actually re-soldering some of the smaller component connections back onto the Boards. THIS Video arguably has the Very BEST Description of How To Do Just THAT:

Last edited: