Just bought the TrailBlazer about a month ago.

Long story short, about a week after I bought it, the keyless stopped working, along with everything in the tailgate. I researched this forum and found that wires can be bad, and the module can be bad too. I pulled the LGM fuse (the 30amp one) and put it back in, voila everything worked again! For about a day. So then I tore the tailgate apart and checked all wires, everything looks perfect. I unplug and plug the LGM back in and everything works again! On the 3rd day I decided to put the tailgate back together. Worked until the next night - WTF

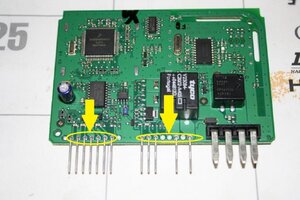

The LGM pins were bent so they weren't making good connection, and one plastic tab was broken on the LGM itself telling me someone was already messing with it. Like I said all the wires look perfect, and I did continuity test on them with no problems. Do the LGM themselves ever go to crap? I bought a new one and tried it but the rear wiper and RAP didn't work.

This is so f-ing frustrating, someone please help me and tell me what to do.

Thanks!

Long story short, about a week after I bought it, the keyless stopped working, along with everything in the tailgate. I researched this forum and found that wires can be bad, and the module can be bad too. I pulled the LGM fuse (the 30amp one) and put it back in, voila everything worked again! For about a day. So then I tore the tailgate apart and checked all wires, everything looks perfect. I unplug and plug the LGM back in and everything works again! On the 3rd day I decided to put the tailgate back together. Worked until the next night - WTF

The LGM pins were bent so they weren't making good connection, and one plastic tab was broken on the LGM itself telling me someone was already messing with it. Like I said all the wires look perfect, and I did continuity test on them with no problems. Do the LGM themselves ever go to crap? I bought a new one and tried it but the rear wiper and RAP didn't work.

This is so f-ing frustrating, someone please help me and tell me what to do.

Thanks!

Drove the dealership and the big fuse was blown, replaced that and fixed all the interior stuff. They programmed the new LGM and now everything is working ok. I will let you all know if it works in three days, that'll be the real test.

Drove the dealership and the big fuse was blown, replaced that and fixed all the interior stuff. They programmed the new LGM and now everything is working ok. I will let you all know if it works in three days, that'll be the real test.