When replacing an AC component, such as a compressor or dryer, in an existing system, and the system was in good condition, should the replacement oil added to the new component (assume the new component is drained of oil that came with it) be the amount drained from the old component or should one add the vehicle specification amount for that component?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

AC replacement oil

- Thread starter Camdo

- Start date

Yes... But before Installing the New Components...Follow this Repair Clean-Out Regimen:

(1) Remove the Liquid and Vapor Lines from the A/C Compressor, Filter Drier, Condenser and Evaporator PRIOR to performing a Clean Out of the Lines.

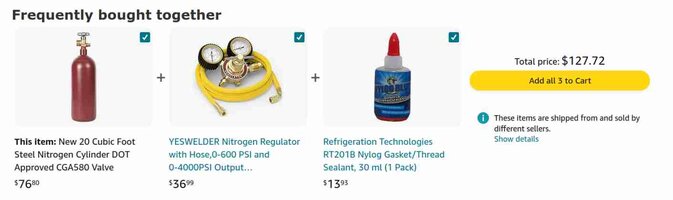

(2) Purge the Lines using a Commercial HVAC System Flush using a Typical Valve Controlled Compressed Air Canister Unit via Compressed Air to deliver the Liquid under enough pressure to Flush out the system. If possible... Flush Out and Purge the Evaporator and the Condenser Unit ...Separately.

(3) In order to ensure the Removal of all the Old Dirt and Old Moisture Contaminated PAG Oil... Remove the In-Line Filter Orifice prior to Flushing and Purging and THEN install a Brand New Filter-Orifice into the Liquid Line AFTER the Flush-Out and Purge Procedures are complete.

(4) NEVER install a Brand New A/C Compressor FIRST and THEN Flush Out or Purge any of those Lines... Otherwise, All that will happen is the residue of Old Metal Particles and Dirt will wind up contaminating the insides of your Brand New Scroll Compressor!

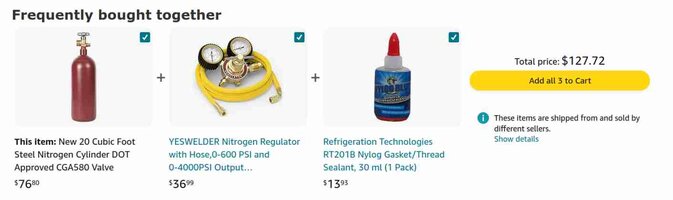

(5) Use Dry Nitrogen @ 10-20 PSI on the Newly Repaired Sealed System BEFORE introducing the New PAG OIL & "FREON" back inside of the system (2 Oz, in the Compressor, 2 Oz in the Accumulator, 2 Oz, in the Condenser). Check your A/C OEM Service Manual for anything more specific on weighing in the R-134A Charge and more precise amounts of PAG Oil ...OF A PARTICULAR NUMBER! Keep each Sub-System Component PLUGGED OFF to prevent the New PAG Oil from soaking up all the Local Atmospheric Moisture from right out of the Air...and RUINING IT!

(6) Allow the Dry Nitrogen to SIT under Low Pressure in the system long enough to absorb the residual Atmospheric Moisture in the Lines and everywhere else where Water can Flash Freeze over inside of the Evaporator Unit and BLOCK the Passage of the R-134A HCFC-CFC.

(7) Do NOT Skip the Dry Nitrogen De-Hydration Phase... as getting a truly "Fresh Start" on a Bone Dry System will ensure years of Top Notch Cooling from the Auto A/C System. Don't be impatient... it might take quite a while for extraneous Water Vapor to escape from inside of all of that Evaporator Capillary Piping.

(8) Use an Inexpensive 2.5 CFPM Vacuum Pump (ALWAYS WITH FRESH, UN-USED VACUUM PUMP OIL.. .NOT PAG OIL) to Evacuate the entire A/C System for around 30 Minutes to One Hour or down to a reasonably Low Micron Level and then Test that the System Will Hold Vacuum afterwards with very little Vacuum Loss for around 10-15 Minutes. A Standard A/C Manifold Gauge should be used in all cases when pulling a Vacuum, followed by the R-134A Charging Activity. TRUST THOSE GAUGES!

(9) Then Weigh in your R-134A Charge and allow the First Can to Normalize throughout the System before Starting the Engine. Once the Low Pressure Sensor Switch engages and allows the New A/C Compressor to "Kick-On" ...finish weighing in the remaining R-134A Charge.

(10) Avoid Over-Charging the System and use an appropriate 'Temperature vs. Pressure' Chart to *fiddle* the system and Tweak the Cold. Once the Accumulator has reached "Beer Can Cold" and the Internal A/C Vents set on HIGH are spewing out Cold Air at around 40 Degrees as per the Needle Thermometer stuck through those Vanes... Quit putting in any additional R-134A. Better to add in a little LESS R-134A ...Than to put in TOO Much.

(1) Remove the Liquid and Vapor Lines from the A/C Compressor, Filter Drier, Condenser and Evaporator PRIOR to performing a Clean Out of the Lines.

(2) Purge the Lines using a Commercial HVAC System Flush using a Typical Valve Controlled Compressed Air Canister Unit via Compressed Air to deliver the Liquid under enough pressure to Flush out the system. If possible... Flush Out and Purge the Evaporator and the Condenser Unit ...Separately.

(3) In order to ensure the Removal of all the Old Dirt and Old Moisture Contaminated PAG Oil... Remove the In-Line Filter Orifice prior to Flushing and Purging and THEN install a Brand New Filter-Orifice into the Liquid Line AFTER the Flush-Out and Purge Procedures are complete.

(4) NEVER install a Brand New A/C Compressor FIRST and THEN Flush Out or Purge any of those Lines... Otherwise, All that will happen is the residue of Old Metal Particles and Dirt will wind up contaminating the insides of your Brand New Scroll Compressor!

(5) Use Dry Nitrogen @ 10-20 PSI on the Newly Repaired Sealed System BEFORE introducing the New PAG OIL & "FREON" back inside of the system (2 Oz, in the Compressor, 2 Oz in the Accumulator, 2 Oz, in the Condenser). Check your A/C OEM Service Manual for anything more specific on weighing in the R-134A Charge and more precise amounts of PAG Oil ...OF A PARTICULAR NUMBER! Keep each Sub-System Component PLUGGED OFF to prevent the New PAG Oil from soaking up all the Local Atmospheric Moisture from right out of the Air...and RUINING IT!

(6) Allow the Dry Nitrogen to SIT under Low Pressure in the system long enough to absorb the residual Atmospheric Moisture in the Lines and everywhere else where Water can Flash Freeze over inside of the Evaporator Unit and BLOCK the Passage of the R-134A HCFC-CFC.

(7) Do NOT Skip the Dry Nitrogen De-Hydration Phase... as getting a truly "Fresh Start" on a Bone Dry System will ensure years of Top Notch Cooling from the Auto A/C System. Don't be impatient... it might take quite a while for extraneous Water Vapor to escape from inside of all of that Evaporator Capillary Piping.

(8) Use an Inexpensive 2.5 CFPM Vacuum Pump (ALWAYS WITH FRESH, UN-USED VACUUM PUMP OIL.. .NOT PAG OIL) to Evacuate the entire A/C System for around 30 Minutes to One Hour or down to a reasonably Low Micron Level and then Test that the System Will Hold Vacuum afterwards with very little Vacuum Loss for around 10-15 Minutes. A Standard A/C Manifold Gauge should be used in all cases when pulling a Vacuum, followed by the R-134A Charging Activity. TRUST THOSE GAUGES!

(9) Then Weigh in your R-134A Charge and allow the First Can to Normalize throughout the System before Starting the Engine. Once the Low Pressure Sensor Switch engages and allows the New A/C Compressor to "Kick-On" ...finish weighing in the remaining R-134A Charge.

(10) Avoid Over-Charging the System and use an appropriate 'Temperature vs. Pressure' Chart to *fiddle* the system and Tweak the Cold. Once the Accumulator has reached "Beer Can Cold" and the Internal A/C Vents set on HIGH are spewing out Cold Air at around 40 Degrees as per the Needle Thermometer stuck through those Vanes... Quit putting in any additional R-134A. Better to add in a little LESS R-134A ...Than to put in TOO Much.

Last edited:

Thank you mrrsm for your response. Your procedure feels pretty cool. I have some questions on how to proceed in implementing your plan:

step 2. Detach and purge each line, condenser and evaporator separately with compressed air and ac flush chemical. Is this equipment what you had in mind?

I assume that each component and line must be capped after flushing while the other components are flushed. It would seem practical that after the chemical flush to shoot the component a blast of nitrogen to flush out any residual chemical and then cap the ends with some sort of plug while servicing the other components. Would these plugs be useful for this purpose:

Step 5 is where I get confused as to how to implement. Lets assume that a new accumulator/dryer and compressor is to be installed. The condenser, evaporator and transmission lines have been cleaned and purged with nitrogen as above, and capped with the plugs shown. Lets say the manufactures spec is for total system PAG oil of 8 oz. As I understand it, the total 8 oz. would be put in the compressor suction port (assuming the compressor was dry) and then all the lines and components would be assembled together. Nitrogen of 10-20 psi would be added via the service line of a manifold gauge set into the ac service ports of the vehicle.

step 6. Allow the low pressure nitrogen to sit about xx minutes so it can act as a desiccant, absorbing any residual moisture in the system. Can you give an estimate how many minutes to allow for this absorption process. How does one know how long is enough?

step 8. Apply vacuum to the system thru the manifold service line to evacuate the nitrogen. Vacuum for 30-60 minutes. Close the manifold valves and test the system has no leaks for 15 minutes.

step 9. If no leaks, add R132a by manufactures specific weight, as you described, thru the manifold service line.

Step 10. I have a question about "fiddle" the system and tweak the cold.

For example,

Specifications from manufactures manual "Temperature vs Pressure" chart:

ambient temperature 68 F

50% relative humidity

low side pressure 25-38 psi

high side pressure 170-210 psi

discharge air temperature 52 F maximum

the system has been charged to the specified weight of R132a

engine is idling 600 rpm

actual readings are:

low side pressure 33 psi (in range)

high side pressure 160 psi (below range)

and discharge air 55 F (too hot)

As I understand your step 10 description, you would add more R132a until discharge air was 52 F or colder, but stop adding if low or high side pressures reached the limit of their specified range. In effect you are saying the manufactures system refrigerant weight specification is only approximate and final determination should be by actual pressure and discharge temperature results?

step 2. Detach and purge each line, condenser and evaporator separately with compressed air and ac flush chemical. Is this equipment what you had in mind?

I assume that each component and line must be capped after flushing while the other components are flushed. It would seem practical that after the chemical flush to shoot the component a blast of nitrogen to flush out any residual chemical and then cap the ends with some sort of plug while servicing the other components. Would these plugs be useful for this purpose:

Step 5 is where I get confused as to how to implement. Lets assume that a new accumulator/dryer and compressor is to be installed. The condenser, evaporator and transmission lines have been cleaned and purged with nitrogen as above, and capped with the plugs shown. Lets say the manufactures spec is for total system PAG oil of 8 oz. As I understand it, the total 8 oz. would be put in the compressor suction port (assuming the compressor was dry) and then all the lines and components would be assembled together. Nitrogen of 10-20 psi would be added via the service line of a manifold gauge set into the ac service ports of the vehicle.

step 6. Allow the low pressure nitrogen to sit about xx minutes so it can act as a desiccant, absorbing any residual moisture in the system. Can you give an estimate how many minutes to allow for this absorption process. How does one know how long is enough?

step 8. Apply vacuum to the system thru the manifold service line to evacuate the nitrogen. Vacuum for 30-60 minutes. Close the manifold valves and test the system has no leaks for 15 minutes.

step 9. If no leaks, add R132a by manufactures specific weight, as you described, thru the manifold service line.

Step 10. I have a question about "fiddle" the system and tweak the cold.

For example,

Specifications from manufactures manual "Temperature vs Pressure" chart:

ambient temperature 68 F

50% relative humidity

low side pressure 25-38 psi

high side pressure 170-210 psi

discharge air temperature 52 F maximum

the system has been charged to the specified weight of R132a

engine is idling 600 rpm

actual readings are:

low side pressure 33 psi (in range)

high side pressure 160 psi (below range)

and discharge air 55 F (too hot)

As I understand your step 10 description, you would add more R132a until discharge air was 52 F or colder, but stop adding if low or high side pressures reached the limit of their specified range. In effect you are saying the manufactures system refrigerant weight specification is only approximate and final determination should be by actual pressure and discharge temperature results?

Step 2: Yes... THAT Device along with THAT Flush is the Best Choice for delivering the HVAC Cleaning Fluid under 20-30 PSI into the Lines for the Flushing and then the Flush & Clean Out of the Condenser and Evaporator. I should advise you NOT to perform this part of the procedure within an enclosed space or garage.

I chose to purchase the appropriate sizes of LONG Clear Acrylic Hoses in order to capture the escaping material as it was flushing clear of these individual components and poking a hole into the Lid of a Five Gallon Bucket , moving that container as far away from my position as possible so as NOT to inhale the Noxious, Highly Vaporous Liquid Flush.

You'll have to look at the Exit and Entrance Ports of the Condenser and the like Ports on the Firewall for the Evaporator and measure them for the Tubing necessary to get a decent seal. Don't use too much Air Pressure and when the Fluid no longer drips or is visible as a Liquid moving through the Line, that should be sufficient. Remember to always Flush the System FROM the Liquid Line side TO the Return Vapor Line...and keep that pattern for the Evaporate and the Condenser.... One Way IN ...One Way OUT. The Vacuum Machine will evacuate all of the residual Flush in due time.

As for sealing up all of the openings during these preparations, it will be especially important if you are NOT prepared to go through ALL of these steps...One after The Other to complete the Entire Job.

Step 5 You should NOT pour in ALL 8 Ounces of PAG Oil into any single component. Putting 2 Ounces in the Accumulator-Drier, 2 Ounces in the Condenser and 2 Ounces in the A/C Compressor...which is designed as a "Scroll Compressor" in order to Compress GAS... NOT NON-COMPRESSIBLE LIQUIDS. Once the PAG Oil is poured into the Compressor... the Pump should be hand cranked to distribute the PAG oil through the Pump Innards and avoid hydraulically locking or damaging the Compressor and then immediately "Capped Off" until it is time to be installed.

Step 6 If you have an abundance of Nitrogen Gas to work with...you can certainly Spray it through the Lines... but if you just Cap Off these components and lines....when you Pull the First Vacuum, the Nitrogen works best if piped into a thoroughly evacuated system. Then just let the Nitrogen sit in the system for around 30 Minutes or so. Under a vacuum...water will sublimate easily once the Dry Nitrogen is exposed to any trace Water Molecules.

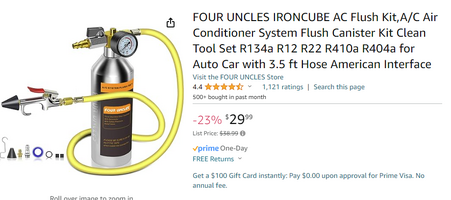

Allow the Dry Nitrogen to exit via depressing the Service Port Schrader Valve down to around 10 PSI and the It follows as necessary to Pull a Second Vacuum for 45 Minutes to an Hour. Use your HVAC Manifold Gauge Set to ensure that the system gets a Deep Vacuum once the Ball Cock Valves are closed off with very little vacuum loss over a ten minute rest period while the Pump remains turned OFF. Using NYLOG Blue on the "O" Ring Fittings and Schrader Pin Valves Seals can help to ensure a good assembly and sealing of the system.

Step 10 The Final Phase of this process requires a bit of Art with the Science...and thus the *Fiddling* Part has to do with "Inching Your Way Up to " the Maximum Charge Weight. The other considerations have to do with the reality of the general condition of the engine and transmission whether or not the vehicle can idle properly.

You MUST have Patience and NOT try to achieve more than might be possible if your ENTIRE A/C System Components are NOT Brand New. After the initial injection of the Weighed In Charge of R-134A... LET THE SYSTEM RUN FOR AT LEAST 15 MINUTES while you keep taking the Air Termps in the Cab. Drive the vehicle around at local and highway speeds and take notice of the changes happening to the Air Temps coming from the Dash Vents.

There is a small canister of a "Coolant Enhancer" available at AutoZone that will allow the injection of that Last 2 Ounces of PAG Oil into the system all in one go through the HVAC Manifold Gauge Service Port that can have a positive effect in getting the Coldest Air out of the Dashboard Vents. Adding in TOO MUCH R-134A will NOT make the system work any better. Do NOT exceed the Recommended Charge Weight of the R-134A

I chose to purchase the appropriate sizes of LONG Clear Acrylic Hoses in order to capture the escaping material as it was flushing clear of these individual components and poking a hole into the Lid of a Five Gallon Bucket , moving that container as far away from my position as possible so as NOT to inhale the Noxious, Highly Vaporous Liquid Flush.

You'll have to look at the Exit and Entrance Ports of the Condenser and the like Ports on the Firewall for the Evaporator and measure them for the Tubing necessary to get a decent seal. Don't use too much Air Pressure and when the Fluid no longer drips or is visible as a Liquid moving through the Line, that should be sufficient. Remember to always Flush the System FROM the Liquid Line side TO the Return Vapor Line...and keep that pattern for the Evaporate and the Condenser.... One Way IN ...One Way OUT. The Vacuum Machine will evacuate all of the residual Flush in due time.

As for sealing up all of the openings during these preparations, it will be especially important if you are NOT prepared to go through ALL of these steps...One after The Other to complete the Entire Job.

Step 5 You should NOT pour in ALL 8 Ounces of PAG Oil into any single component. Putting 2 Ounces in the Accumulator-Drier, 2 Ounces in the Condenser and 2 Ounces in the A/C Compressor...which is designed as a "Scroll Compressor" in order to Compress GAS... NOT NON-COMPRESSIBLE LIQUIDS. Once the PAG Oil is poured into the Compressor... the Pump should be hand cranked to distribute the PAG oil through the Pump Innards and avoid hydraulically locking or damaging the Compressor and then immediately "Capped Off" until it is time to be installed.

Step 6 If you have an abundance of Nitrogen Gas to work with...you can certainly Spray it through the Lines... but if you just Cap Off these components and lines....when you Pull the First Vacuum, the Nitrogen works best if piped into a thoroughly evacuated system. Then just let the Nitrogen sit in the system for around 30 Minutes or so. Under a vacuum...water will sublimate easily once the Dry Nitrogen is exposed to any trace Water Molecules.

Allow the Dry Nitrogen to exit via depressing the Service Port Schrader Valve down to around 10 PSI and the It follows as necessary to Pull a Second Vacuum for 45 Minutes to an Hour. Use your HVAC Manifold Gauge Set to ensure that the system gets a Deep Vacuum once the Ball Cock Valves are closed off with very little vacuum loss over a ten minute rest period while the Pump remains turned OFF. Using NYLOG Blue on the "O" Ring Fittings and Schrader Pin Valves Seals can help to ensure a good assembly and sealing of the system.

Step 10 The Final Phase of this process requires a bit of Art with the Science...and thus the *Fiddling* Part has to do with "Inching Your Way Up to " the Maximum Charge Weight. The other considerations have to do with the reality of the general condition of the engine and transmission whether or not the vehicle can idle properly.

You MUST have Patience and NOT try to achieve more than might be possible if your ENTIRE A/C System Components are NOT Brand New. After the initial injection of the Weighed In Charge of R-134A... LET THE SYSTEM RUN FOR AT LEAST 15 MINUTES while you keep taking the Air Termps in the Cab. Drive the vehicle around at local and highway speeds and take notice of the changes happening to the Air Temps coming from the Dash Vents.

There is a small canister of a "Coolant Enhancer" available at AutoZone that will allow the injection of that Last 2 Ounces of PAG Oil into the system all in one go through the HVAC Manifold Gauge Service Port that can have a positive effect in getting the Coldest Air out of the Dashboard Vents. Adding in TOO MUCH R-134A will NOT make the system work any better. Do NOT exceed the Recommended Charge Weight of the R-134A

Last edited:

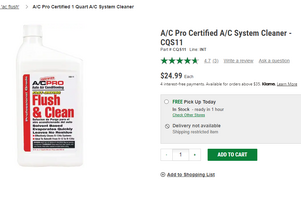

There is one other condition worth noting that can seriously affect the performance of the HVAC Cooling in the System: A Dirt and-or Debris Clogged Condensing Unit. This requires removing the Front Panels of the Nose of the Trailblazer -Envoy in order to expose the Condenser well enough to apply a Non-Corrosive, Foaming Soapy Solution to dissolve away the accumulation of Dirt & Debris that can restrict the ability of those Fins to reject the Heat that builds up when the R-134A is moved from a Gaseous State and getting compressed down into a Liquid One generating Heat in the process.

You might be surprised to find Very Large Leaves and even on occasion, Inhaled Plastic Bags that can cover enough of the Condenser Fin Surface Areas to seriously reduce the Heat Rejection necessary for the Gas to eventually become a Hot Liquid on its way through the Filter - Orifice and thence into the Accumulator and allow a Rapid Phase Change during its Expansion that will absorb the Cabin Heat necessary to make the Physics involved during this Phase Change ...to happen. From there, it will allow for the serious Chill Down of the Under-Dash Evaporator as the Blower Motor drives ambient Cabin & Outside Air through the Dashboard Vents....and Cools The Cabin Down.

Amazon carries a bewildering array of these necessary products to suit your needs:

You might be surprised to find Very Large Leaves and even on occasion, Inhaled Plastic Bags that can cover enough of the Condenser Fin Surface Areas to seriously reduce the Heat Rejection necessary for the Gas to eventually become a Hot Liquid on its way through the Filter - Orifice and thence into the Accumulator and allow a Rapid Phase Change during its Expansion that will absorb the Cabin Heat necessary to make the Physics involved during this Phase Change ...to happen. From there, it will allow for the serious Chill Down of the Under-Dash Evaporator as the Blower Motor drives ambient Cabin & Outside Air through the Dashboard Vents....and Cools The Cabin Down.

Amazon carries a bewildering array of these necessary products to suit your needs:

Last edited:

spfautsch

Member

No offense mrrsm, but this seems extremely over-baked. Purging with nitrogen seems excessive. Anyone servicing AC should instead be drawing a vacuum on the system to evaporate and remove any moisture, as it also makes charging the first can of refrigerant 100x easier. If you don't have a vacuum pump, the price of one will likely be 1/2 to 1/3 the cost of a cylinder of nitrogen.

The OP said there were no mechanical failures. To me that indicates that if the expansion orifices are clean, recharge the SOB and go on with life. On a system as big as the GMT36x / 37x platform hosts, flushing all the hoses and evaporators is a monumental task that should only be carried out if deemed absolutely necessary.

To answer your original question Camdo, if replacing one component you'll need to replace the same volume of oil that was drained from said component. If it was the receiver-dryer, you may want to add a bit extra for good measure because there's a dessicant bag in there that will hold a considerable amount of PAG that will take days or weeks to completely drain out. But it's not rocket science. You're not going to kill the compressor if the system is 1 or 2 ounces under or over-filled with oil.

One thing I'll strongly recommend is replacing both service valve cores, particularly the high-pressure side. I've encountered numerous 2004 and newer R134a systems where the only failure was the $8 high pressure service valve leaking all the refrigerant out.

Draw a vacuum on it and charge with the prescribed amount of R134a (in the case of the 3rd row / extended wheelbase variant is 48 oz or 4 cans). Bob's your uncle and Fannie's your aunt (it's an easy fix).

The OP said there were no mechanical failures. To me that indicates that if the expansion orifices are clean, recharge the SOB and go on with life. On a system as big as the GMT36x / 37x platform hosts, flushing all the hoses and evaporators is a monumental task that should only be carried out if deemed absolutely necessary.

To answer your original question Camdo, if replacing one component you'll need to replace the same volume of oil that was drained from said component. If it was the receiver-dryer, you may want to add a bit extra for good measure because there's a dessicant bag in there that will hold a considerable amount of PAG that will take days or weeks to completely drain out. But it's not rocket science. You're not going to kill the compressor if the system is 1 or 2 ounces under or over-filled with oil.

One thing I'll strongly recommend is replacing both service valve cores, particularly the high-pressure side. I've encountered numerous 2004 and newer R134a systems where the only failure was the $8 high pressure service valve leaking all the refrigerant out.

Draw a vacuum on it and charge with the prescribed amount of R134a (in the case of the 3rd row / extended wheelbase variant is 48 oz or 4 cans). Bob's your uncle and Fannie's your aunt (it's an easy fix).

Last edited:

Thanks for the feed back spfautsch I feel less guilty for having done what I did. I took to heart the method mrrsm described. It sounded correct with high probability of "beer can cold" success. I thought and thought about it. My shop air is full of water. I would not paint with it and I did not want to fill my AC lines with it. Getting a bottle of nitrogen and using it in conjunction with the chemical clean was just beyond my reach. I replaced the AC compressor because the clutch was squeaking replace me for the last five years. I replaced the dryer/accumulator and orifice as it is recommended by the compressor manufacturer. The whole job came about because the water pump needed replacing and I thought I would give the engine a front end overhaul (water pump, AC compressor, tensioner, idler, and radiator hoses) My Envoy has 248,000 miles on it and I love it so very much.

I drained 1.1 oz. of PAG from the old compressor and that gave impetus to my original post. I decided to put 2.0 oz. in the new compressor, as 1.1 seemed a little light. I found out later, the GM manual has a footnote that says replace with 2.0 oz. or the amount drained if more (page 1-6). So in retrospect, I did the right thing. Nothing drained from the old dryer, but figuring the desiccant was holding the PAG, I added 2.0 oz. to the new one, the amount the manual specifies.

When replacing the orifice, I thought of mrrsm and the clean line technique, as there was some junk in there. I don't know if it was inhibiting flow but it wasn't pristine. Oh well it is what it is and I got what I have and put it all back together with a new orifice, If I had the setup I would have blown the lines clean, but I wasn't properly prepared for that.

I applied vacuum (-32 in-Hg) overnight hoping to rid the system of any lingering water, and check for leaks. Final results of the GM manual "AC System Performance Test" (page 1-8) spec shown in ( ),

relative humidity estimated less than 50%,

84F ambient,

low side 39 psi (31-42),

high side 160 psi (160-200),

outlet temperature 58F (57 max).

So all okay but outlet temperature just 1 degree out of spec. It was a pass for me.

I do wonder if mrrsm's clean line technique would have changed the results, but I am satisfied with what I got. No better or worse than what I had in way of AC performance. The real bonus of what I did is the quietness of the engine. It is now my pleasure to turn off the radio and just listen to the sound of silence gliding thru the by ways of country roads.

I drained 1.1 oz. of PAG from the old compressor and that gave impetus to my original post. I decided to put 2.0 oz. in the new compressor, as 1.1 seemed a little light. I found out later, the GM manual has a footnote that says replace with 2.0 oz. or the amount drained if more (page 1-6). So in retrospect, I did the right thing. Nothing drained from the old dryer, but figuring the desiccant was holding the PAG, I added 2.0 oz. to the new one, the amount the manual specifies.

When replacing the orifice, I thought of mrrsm and the clean line technique, as there was some junk in there. I don't know if it was inhibiting flow but it wasn't pristine. Oh well it is what it is and I got what I have and put it all back together with a new orifice, If I had the setup I would have blown the lines clean, but I wasn't properly prepared for that.

I applied vacuum (-32 in-Hg) overnight hoping to rid the system of any lingering water, and check for leaks. Final results of the GM manual "AC System Performance Test" (page 1-8) spec shown in ( ),

relative humidity estimated less than 50%,

84F ambient,

low side 39 psi (31-42),

high side 160 psi (160-200),

outlet temperature 58F (57 max).

So all okay but outlet temperature just 1 degree out of spec. It was a pass for me.

I do wonder if mrrsm's clean line technique would have changed the results, but I am satisfied with what I got. No better or worse than what I had in way of AC performance. The real bonus of what I did is the quietness of the engine. It is now my pleasure to turn off the radio and just listen to the sound of silence gliding thru the by ways of country roads.

Just for Reference to interested followers of this Thread ... *Bump* Post #2 (EDIT: Amazon carries inexpensive N2 Product Listings via the GMT Nation Link at the bottom of the Post)

One other thing worth mentioning... Whenever choosing a Vacuum Pump, getting more "PULL" upon a *Wet* Automotive HVAC System than is usually expected when using a typical HF 2.5 CFPM Vacuum Pump by the operation of a borrowed 6-8 CFPM Pro Pump used in Commercial and Residential HVAC Jobs can actually vacuum so fast that the Evaporating Water Molecules inside the Evaporator capillary tubes will instantly Freeze ...Rock Hard.

The very act of "Evaporation" in and of itself is a Cooling Process that if done too efficiently, can cause a much too rapid Phase Change upon the Hidden or Trapped Water and if it remains inside of any HVAC System as a result, over time, the cooling performance can become sub-optimal and even allow for the Hidden Water to combine with the R-134A and create acids that can eventually etch and affect the copper coils inside of the A/C Scroll Compressor.

Contrary to popular belief... ICE as a Solid Substance will NOT easliy sublimate back into a Gas under a VERY High Vacuum condition and therefore, if present, will make its extrication from the small confines of the inner tubing very difficult to achieve, no matter how long the Vacuum Pump runs.

The reason for my recommending the use of the Low Pressure Dry Nitrogen is that it allows for the Residual Water in the system to be *Sopped* up like a Sponge ...FIRST... and thus, it makes the Desiccation of the internal system possible BEFORE injecting either the Hygro-scopic (with a "G") PAG Oil or wind up accidentally, prematurely Saturating the Silica Gel Packet inside of a Brand New Accumulator.

One other thing worth mentioning... Whenever choosing a Vacuum Pump, getting more "PULL" upon a *Wet* Automotive HVAC System than is usually expected when using a typical HF 2.5 CFPM Vacuum Pump by the operation of a borrowed 6-8 CFPM Pro Pump used in Commercial and Residential HVAC Jobs can actually vacuum so fast that the Evaporating Water Molecules inside the Evaporator capillary tubes will instantly Freeze ...Rock Hard.

The very act of "Evaporation" in and of itself is a Cooling Process that if done too efficiently, can cause a much too rapid Phase Change upon the Hidden or Trapped Water and if it remains inside of any HVAC System as a result, over time, the cooling performance can become sub-optimal and even allow for the Hidden Water to combine with the R-134A and create acids that can eventually etch and affect the copper coils inside of the A/C Scroll Compressor.

Contrary to popular belief... ICE as a Solid Substance will NOT easliy sublimate back into a Gas under a VERY High Vacuum condition and therefore, if present, will make its extrication from the small confines of the inner tubing very difficult to achieve, no matter how long the Vacuum Pump runs.

The reason for my recommending the use of the Low Pressure Dry Nitrogen is that it allows for the Residual Water in the system to be *Sopped* up like a Sponge ...FIRST... and thus, it makes the Desiccation of the internal system possible BEFORE injecting either the Hygro-scopic (with a "G") PAG Oil or wind up accidentally, prematurely Saturating the Silica Gel Packet inside of a Brand New Accumulator.

Last edited:

spfautsch

Member

Final results of the GM manual "AC System Performance Test" (page 1-8) spec shown in ( ),

relative humidity estimated less than 50%,

84F ambient,

low side 39 psi (31-42),

high side 160 psi (160-200),

outlet temperature 58F (57 max).

So all okay but outlet temperature just 1 degree out of spec. It was a pass for me.

That's better than great for a system with that many miles on it! Aside from refrigerant leaks and catastrophic compressor failures, the next biggest killer of A/C efficiency I've seen is the condenser core becoming plugged with sand / gravel. When I rehabbed the A/C system in my '95 Vette, it was blatantly clear the sand & small gravel were a major impediment to airflow through the core. Unfortunately a new condenser for one of those is phenomenally expensive, when they are available (a rare event).

Keep doing what you have to in order to keep these vehicles on the road. When they're gone we'll be stuck in a prison cell for our remaining years with a perpetually high Elon Musk.