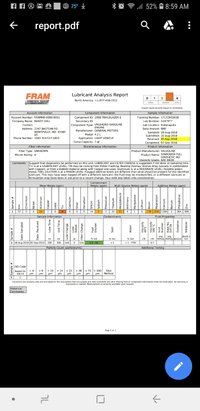

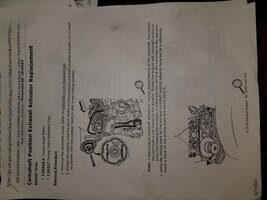

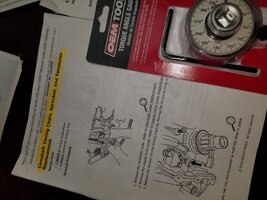

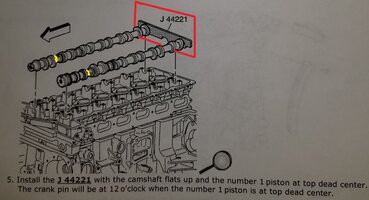

I have a 2008 trailblazer 3LT 4.2. This truck has never used oil. I must admit due to my 7 day work schedule, the routine maintenance often gets put on the back burner. It started with a low oil shut engine off message while on an incline of a boat ramp. I'm ashamed to admit it was down almost 4 quarts. I topped it off and had to help son move back to college the next day 100 miles away. I swallowed my pride and paid the local valvoline 100 bucks for a full synthetic change. I drove it to his school, and pulled a 16ft trailer back. On the way home I thought I noticed a tick on the highway only when decelerating with throttle off. A few days later I heard a loud knock/clatter and my heart sank. At this point I was sure the engine was done. Once warm it has a barely noticeable knock at idle. If u bring the rpms up the loud knock comes on about 1900rpm and disappears around 2500. I put a stethoscope on every inch of motor and pinpointed it to valve cover right over cam phaser and timing chain. I compression tested it and had 245,230,240,240,220,230. I pulled the vvt solenoid and screens were clogged. I currently have the valve cover off and can see nothing obvious.i can move the phaser ever so slightly with alot of force. The chain seems tight and looks ok. I have owned this since new and it has 130,000 on it now. I dont mow if i should replace all the timing components, or just solenoid, sensor, and phaser. The only work that has been done is water pump, hubs, etc. And the diff did fail at about 100,000, which i did myself(it was rough), but thats it. Any insight or opinions would be greatly appreciated

.

.