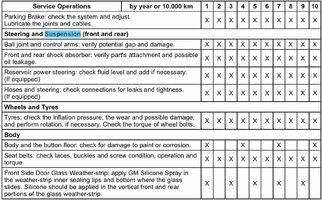

For a while now, I've been chasing an intermittent squeaking issue on the driver's side front wheel. It would only occur at low speeds, on sharp right turns, like pulling into a parking spot, or turning at an intersection. After spraying silicone spray around all the joints, the noise would eventually go away for weeks or months, and then come back.

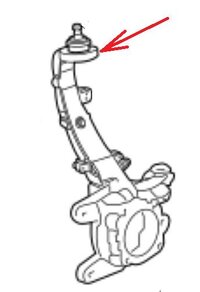

Finally think I singled out the issue, when spraying the UBJ pinch bolt, the squeaking would go away after a few turns. Pulled out the grease gun and after a single squeeze, the grease came out BEFORE the fitting. Suspecting a clogged zirk, I pulled it to test, but grease flowed freely through it, so that means problem with the UBJ correct? Are there any options other than replacement?

Finally think I singled out the issue, when spraying the UBJ pinch bolt, the squeaking would go away after a few turns. Pulled out the grease gun and after a single squeeze, the grease came out BEFORE the fitting. Suspecting a clogged zirk, I pulled it to test, but grease flowed freely through it, so that means problem with the UBJ correct? Are there any options other than replacement?

But when I disconnected the control arm to do the testing with the boot, I was able to move the ball joint easily by hand, it was smooth without any play, so doesn't have any problems other than lubricity.

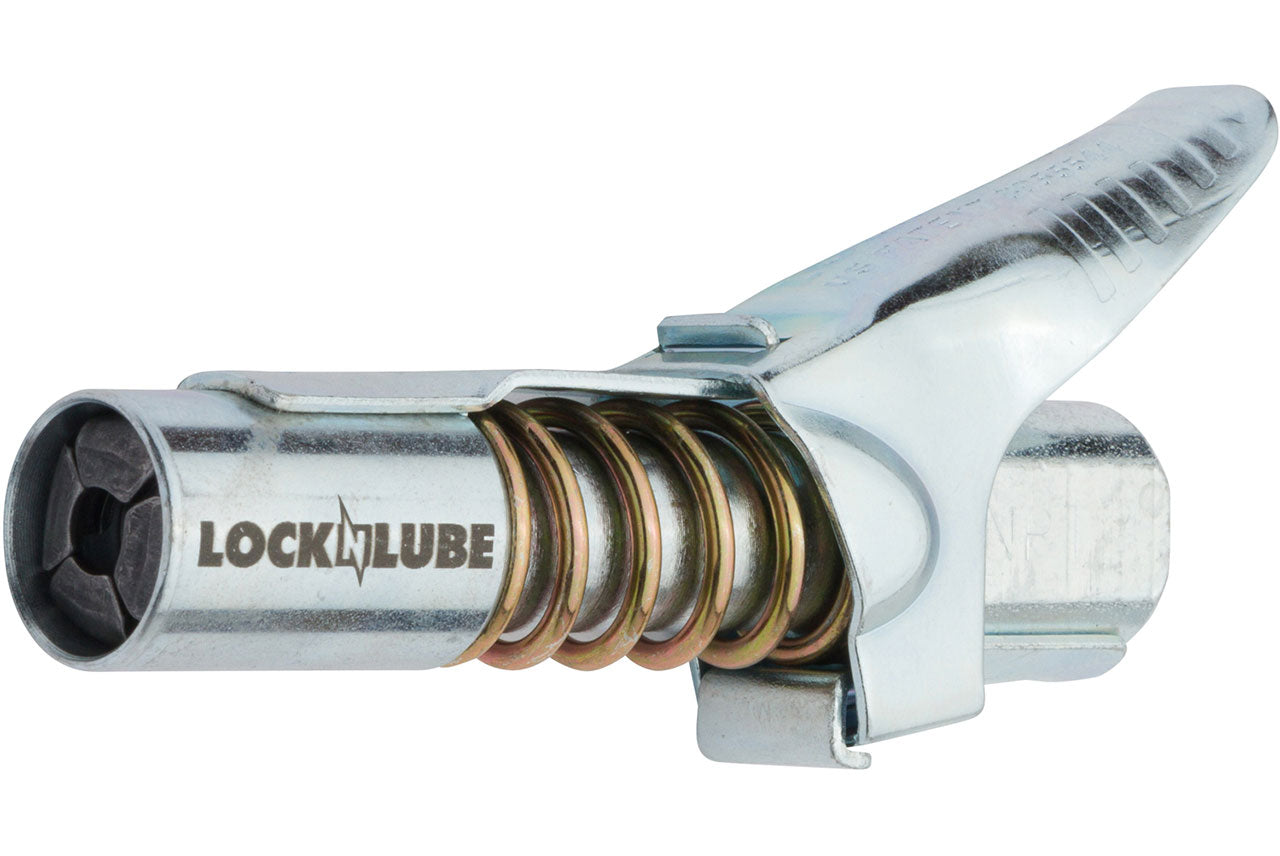

But when I disconnected the control arm to do the testing with the boot, I was able to move the ball joint easily by hand, it was smooth without any play, so doesn't have any problems other than lubricity. I saw some of the grease needles that have a zerk fitting, so you can use them with the grease gun and not have to buy a syringe. That will likely be a new addition to the tool box in the coming weeks

I saw some of the grease needles that have a zerk fitting, so you can use them with the grease gun and not have to buy a syringe. That will likely be a new addition to the tool box in the coming weeks