I know this has been done to death but I've been dealing with a check engine light for about a year now. Every time I clear it comes right back on the same day. Replaced the purge valve and no change so I left it. No problem with drivability till now. All of a sudden my wife ran out of gas with just over a quarter of a tank left! Now it's staying on full and goes down just slightly after diving it after a week. Did some research and read that the tank could be full of pressurized air? Do not have a scan tool and can't afford a smoke test or take it to a shop. Tried to put gas in it today but only took 6 gallons before I heard it coming up the filler tube. No way it can be full. Anything I can check or what to look for. I don't know why or what is bad. Thought it could be the sending unit but the tank and pump were replaced 2 years ago. Any way to check it without diagnostic equipment? Just a cheap code reader and multimeter at my disposal.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

PO442

- Thread starter Stuntmanmike1977

- Start date

Source:

www.vehicleservicepros.com

www.vehicleservicepros.com

After that easy check, you should look at the freeze frame data with your scan tool. This data contains a listing of what was occurring at the time the code was set. Depending on the vehicle, some of the data available may include how long the engine was running, the engine and vehicle speed, engine temperature, and possibly the fuel level. All of this information may assist you in determining what caused the fault. Having it available to you will also enable you to operate the vehicle under the same conditions after the repair to make sure the code doesn’t reset.

After you have the freeze frame data, refer to your vehicle information source to determine what the enabling criteria (the operating conditions) are to trigger the fault code. This is critical if you’ll be performing a drive cycle to verify your repair.

Most vehicles use similar criteria for monitoring the evap system and will need 15 to 85 percent fuel level. If the fuel level is either above 85 percent or below 15 percent, the test won’t run, and you’ll likely spend hours and multiple drive cycles attempting to validate your repairs without success. These vehicles also monitor engine and ambient air temperature. Upon startup, the two temperatures need to be within 10 degrees of each other. If not, the computer assumes it’s not a cold start and will not perform an evap test.

Another common condition that’s difficult to overcome is the ambient air temperature. Many vehicles will not run an evap test if the air temperature is above 104 degrees F or below 32 degrees F. That’s because tank pressure can change drastically either above or below those temperatures, making leak detection difficult.

The evap monitor test needs multiple tests to either pass or fail, so your scan tool can be used to look at Mode $06 information to see which part of the evap system malfunctioned. This is done by observing the Mode $06 data to see specifically which part of the evap test failed, which allows you to get information from your vehicle information system about that aspect of the evap test process. You can then use that as a starting point for your testing.

Your scan tool also has the ability to control some features of the evap monitor test as well as monitor the datastream to see if it’s functioning. Many scan tools will allow you to perform what is commonly known as a “Service Bay Test”, basically an electrical test of the purge and vent functions of the system. Using bidirectional controls and monitoring various PID’s, you will also be able to see if the purge valve is opening and closing properly by monitoring oxygen sensor voltage, or, with some vehicles, fuel tank pressure.

One of the best tools to locate evap system leaks is a diagnostic smoke machine. Connecting a smoke machine allows you to easily observe any trace of smoke that would indicate a leak, but in some cases, you will need to use the smoke machine and a little ingenuity to find a leak. I have had multiple vehicles that had a faulty purge solenoid which did not completely close, thereby allowing the system to lose pressure (vacuum).

Even though the system was still closed to the atmosphere, the computer system detected a leak. The way I tested for a faulty solenoid was to connect the smoke machine to the system, then disconnect the hose from the purge solenoid to determine if there was a leak. A helpful hint for finding traces of smoke, especially in a brightly lit shop, is to wave a laser pointer around the area of a suspected leak. The laser light will highlight any faint traces of smoke.

Scan tools are essential tools ... but not the only tools

The information and products that work alongside your scan tool for a complete repair.

Issue one: P0442 fault code – Small leak detected in evaporative system

The easiest check to perform first with any evaporative system (evap) leak is to make sure the fuel cap is present and tightened properly. Even if the cap is tight, it may be the cause of the leak, but in this case, someone has already tightened the cap.After that easy check, you should look at the freeze frame data with your scan tool. This data contains a listing of what was occurring at the time the code was set. Depending on the vehicle, some of the data available may include how long the engine was running, the engine and vehicle speed, engine temperature, and possibly the fuel level. All of this information may assist you in determining what caused the fault. Having it available to you will also enable you to operate the vehicle under the same conditions after the repair to make sure the code doesn’t reset.

After you have the freeze frame data, refer to your vehicle information source to determine what the enabling criteria (the operating conditions) are to trigger the fault code. This is critical if you’ll be performing a drive cycle to verify your repair.

Most vehicles use similar criteria for monitoring the evap system and will need 15 to 85 percent fuel level. If the fuel level is either above 85 percent or below 15 percent, the test won’t run, and you’ll likely spend hours and multiple drive cycles attempting to validate your repairs without success. These vehicles also monitor engine and ambient air temperature. Upon startup, the two temperatures need to be within 10 degrees of each other. If not, the computer assumes it’s not a cold start and will not perform an evap test.

Another common condition that’s difficult to overcome is the ambient air temperature. Many vehicles will not run an evap test if the air temperature is above 104 degrees F or below 32 degrees F. That’s because tank pressure can change drastically either above or below those temperatures, making leak detection difficult.

The evap monitor test needs multiple tests to either pass or fail, so your scan tool can be used to look at Mode $06 information to see which part of the evap system malfunctioned. This is done by observing the Mode $06 data to see specifically which part of the evap test failed, which allows you to get information from your vehicle information system about that aspect of the evap test process. You can then use that as a starting point for your testing.

Your scan tool also has the ability to control some features of the evap monitor test as well as monitor the datastream to see if it’s functioning. Many scan tools will allow you to perform what is commonly known as a “Service Bay Test”, basically an electrical test of the purge and vent functions of the system. Using bidirectional controls and monitoring various PID’s, you will also be able to see if the purge valve is opening and closing properly by monitoring oxygen sensor voltage, or, with some vehicles, fuel tank pressure.

One of the best tools to locate evap system leaks is a diagnostic smoke machine. Connecting a smoke machine allows you to easily observe any trace of smoke that would indicate a leak, but in some cases, you will need to use the smoke machine and a little ingenuity to find a leak. I have had multiple vehicles that had a faulty purge solenoid which did not completely close, thereby allowing the system to lose pressure (vacuum).

Even though the system was still closed to the atmosphere, the computer system detected a leak. The way I tested for a faulty solenoid was to connect the smoke machine to the system, then disconnect the hose from the purge solenoid to determine if there was a leak. A helpful hint for finding traces of smoke, especially in a brightly lit shop, is to wave a laser pointer around the area of a suspected leak. The laser light will highlight any faint traces of smoke.

Thanks for all that info. The first thing I checked was the fuel cap but after always pushing down on it and turn it about half a dozen clicks it does wiggle back and forth. Third different cap I tried. Don't know if I can add another thin o-ring to try to seal better? Really can't afford another fuel filler tube. Was a less expensive one I replaced the rotted one with, just have a little trouble there. Is the slight wiggle normal or should there be no movement once tight? I'll try to scan the data but my code reader is very limited and I don't believe it has mode$6 whatever that is. I'm very electronically challenged but I will try. Thank you.

The outer "shell" of the cap is loose even when it is tight ... by design. The lower portion of the cap that engages the fuel pipe (female section) is the "sealing" component. It must be tight.

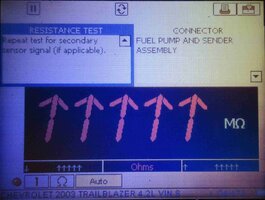

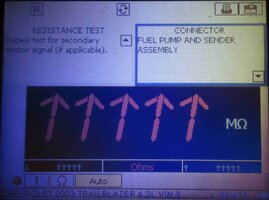

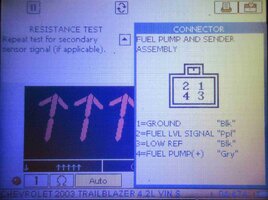

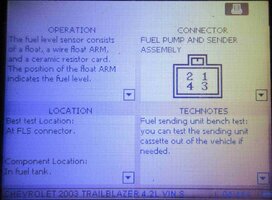

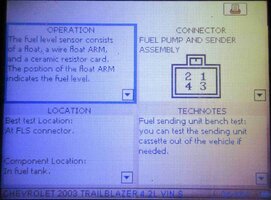

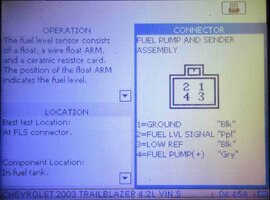

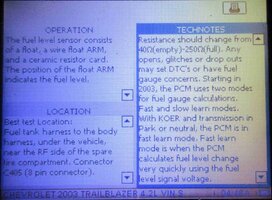

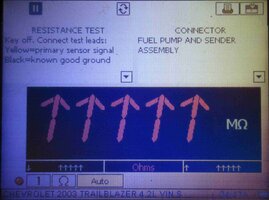

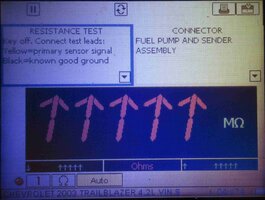

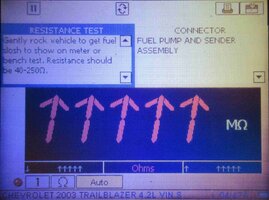

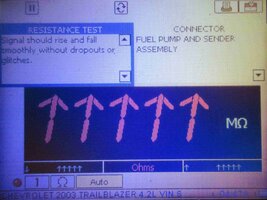

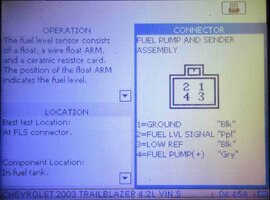

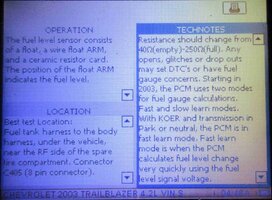

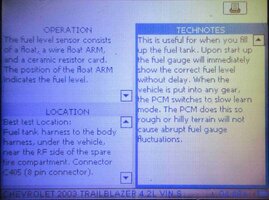

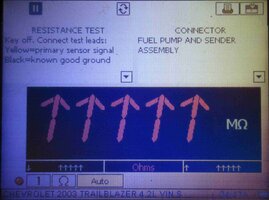

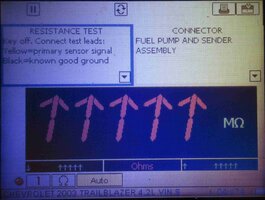

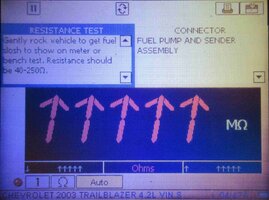

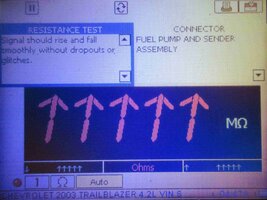

You can read the resistance of the sensor at the cabling going to the pcm... carefully. Attached is example of the expected resistance. That is unlikely to solve your p0442 issue but maybe you have multiple issues / onion skins.

What is the history of your p0442... was it there before the fuel pipe replacement?

You can read the resistance of the sensor at the cabling going to the pcm... carefully. Attached is example of the expected resistance. That is unlikely to solve your p0442 issue but maybe you have multiple issues / onion skins.

What is the history of your p0442... was it there before the fuel pipe replacement?

Attachments

Mooseman

Moderator

I do remember a cap issue with aftermarket replacement filler tubes where the original cap didn't fit on it. Had to use another aftermarket cap.

Yes it was there before. Thought the rusty crusty old filler tube was the culprit. Don't know if it matters but the fuel tank pressure switch had moisture in the sensor, a bent terminal and was filthy on the inside. Bent the tab back straight and sprayed it out with contact cleaner. Still no change. Oh, it's a PO440 code but I believe it's pretty much similar

Your BFF when it comes to Cleaning Connectors that have been subjected to a combination of Vibrations acting in concert with Road Dirt & Grit to Erode the Electrical Contact Tines for both the Male & Female Sides of the Harnesses and allow RUST to settle in ...is to Un-Plug them and Liberally Spray out BOTH Sides with CRC Electrical Solvent and then allow BOTH sides to Completely DRY OUT B4 Re-Attaching them and, if needs be... use additional Bindings of Snug Zip-Ties.

In the cases of Very High Mileage Vehicles operating in Very Dirty, Dusty and Rough Grade Environments where the Vehicles will suffer Wear & Tear of the Front & Rear Suspensions and have Bad Motor Mounts and Transmission Mounts...Dynamic Motions imparted into such non-solid state electrical interfaces...can invite problems illustrated in your Images. Such conditions can invite Electrical Arcing in between the Harness Connectors and thereby... Destroy their Protective Zinc and Cadmium Plating.

SAFETY OBSERVATION:

NEVER Expose any Fluorine Hydro-Carbon Based Cleaning Solvents to any Open Flames or around anything that is Glowing Incandescently HOT... such as when Casting Metal Components or when around ARC Welding or OPEN FLAME Welding ...as these conditions can produce THE DEADLY GAS: PHOSGENE.

Hint: THIS is Why We NEVER ARC or GAS WELD upon Old Teflon Coated Aluminum Pans. Teflon = PTFE (Poly-Tetra-Fluoro-Ethelyne) at 900 Degrees Farenheidt, Teflon converts to PHOSGENE GAS!

The Dangerous Results of having even SLIGHT Inhalation can cause INSTANTANEOUS DEATH in the worst case scenarios... or Permanent Paralysis in the least cases... if ANY such unfortunate events should occur. ALWAYS... RTFL (Read The F****** Labels!)

www.thefabricator.com

www.thefabricator.com

In the cases of Very High Mileage Vehicles operating in Very Dirty, Dusty and Rough Grade Environments where the Vehicles will suffer Wear & Tear of the Front & Rear Suspensions and have Bad Motor Mounts and Transmission Mounts...Dynamic Motions imparted into such non-solid state electrical interfaces...can invite problems illustrated in your Images. Such conditions can invite Electrical Arcing in between the Harness Connectors and thereby... Destroy their Protective Zinc and Cadmium Plating.

SAFETY OBSERVATION:

NEVER Expose any Fluorine Hydro-Carbon Based Cleaning Solvents to any Open Flames or around anything that is Glowing Incandescently HOT... such as when Casting Metal Components or when around ARC Welding or OPEN FLAME Welding ...as these conditions can produce THE DEADLY GAS: PHOSGENE.

Hint: THIS is Why We NEVER ARC or GAS WELD upon Old Teflon Coated Aluminum Pans. Teflon = PTFE (Poly-Tetra-Fluoro-Ethelyne) at 900 Degrees Farenheidt, Teflon converts to PHOSGENE GAS!

The Dangerous Results of having even SLIGHT Inhalation can cause INSTANTANEOUS DEATH in the worst case scenarios... or Permanent Paralysis in the least cases... if ANY such unfortunate events should occur. ALWAYS... RTFL (Read The F****** Labels!)

Arc Welding 101: Cleaning material with brake cleaner before welding

Combining welding and brake cleaners can lead to serious illness, permanent damage to your internal organs, or even death.

Attachments

Last edited:

That's what I did. And carefully bent the pins straight. There was also moisture inside. Since I did that the engine light has been off for 2 days now. Probably will come back on but, fingers crossed.

Had a thought. Been having issues, not for a couple weeks now but, the ABS light was coming on and when it did scan tool revealed it was getting false speed sensor readings and erratic pulse data. Could that have anything to do with the fuel gauge stuck at full with truck running and the computer telling me I'm getting up to 38mpg?

Mooseman

Moderator

Ok, just a thought. Just gonna have to put fuel in it every couple days till I can afford a new pump/sending unit and a place to drop the tank.

Before you Replace the Fuel Pump without actual Proof that IT is THE Actual Problem...You owe it to yourself to visit THIS Link below and follow the cascade of On-Topic GMT Nation Threads where the same problems of 'FUELING SUDDENLY STOPS ...WHEN GASSING UP' Threads may have been sorted out ... and see if there are other aspects of the Fueling System Components involved here that may prove to be the ACTUAL Cause & Origin of the Problem... And perhaps... Wind up being a Whole LOT Less Aggravating and Expensive to Repair or Replace. :>)

Using the "Search" Feature on the GMT Nation Main Forum Page (Upper Right Side) will allow you to find MORE On Topic Threads using that same Search String similar to: "Fueling Suddenly STOPS", etc.

Using the "Search" Feature on the GMT Nation Main Forum Page (Upper Right Side) will allow you to find MORE On Topic Threads using that same Search String similar to: "Fueling Suddenly STOPS", etc.

Last edited:

Well, that's only one of the issues. Fuel gauge still reads full but returns to empty when I shut the truck off as it should and says I'm getting up to 36MPG? Engine light has been off for 4 days now. I'll try to look at the charcoal canister next. Without an engine light indicating a problem I don't really know where to start. What about pulling the fill hose off the tank itself releasing any pressure that way?

The Very First Imperatives (Questions) for Mechanics in ALL Diagnostic Situations are as follows:

(1) What Does the Failing System DO to Make the Vehicle Run Properly?

(2) Where are ALL of the System's Sub-Components within the Vehicle?

(3) How can I gain access to its Harnesses and Connectors so that Diagnostic Tools can be Hooked Up for Testing and Analyzing Each One?

(4) What are the EXPECTED Diagnostic Measurements for the System to Operate Normally?

Hmmm... THAT is all a LOT easier SAID than DONE...Right? Of course. Outside of Dealerships and Pro Shops, not many people have either the Sophisticated Diagnostic Equipment necessary or the Experience to use it all to run such Diagnostic Problems to Ground....Yes?

But Tonight is YOUR Lucky Night... Because I DO. :>)

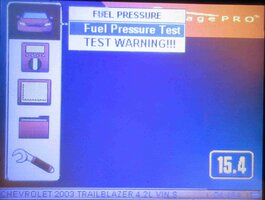

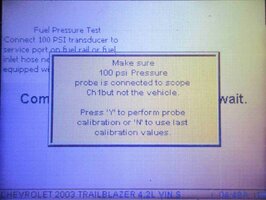

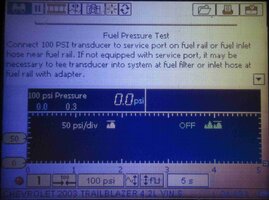

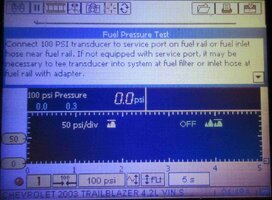

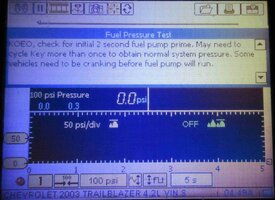

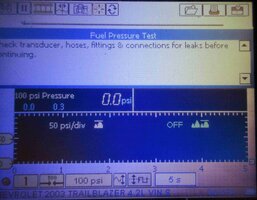

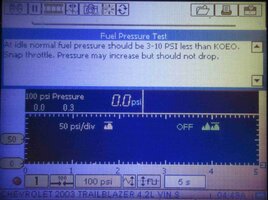

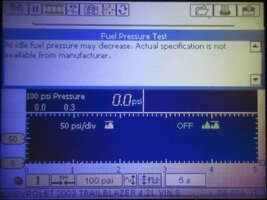

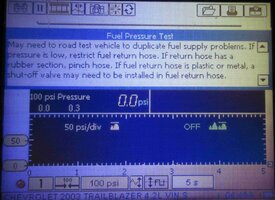

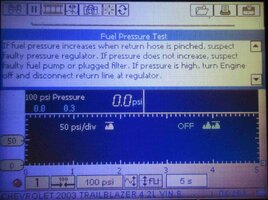

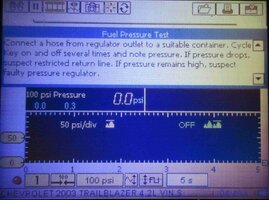

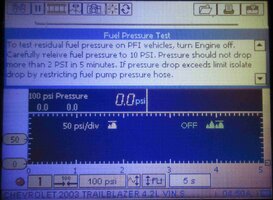

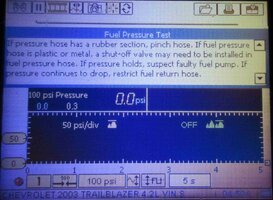

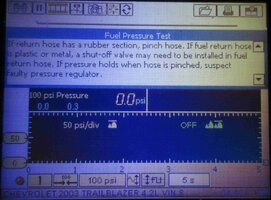

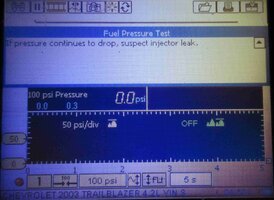

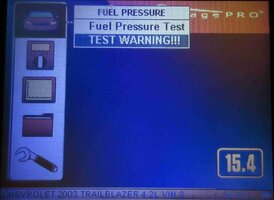

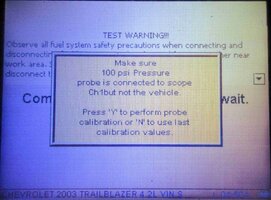

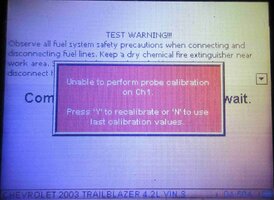

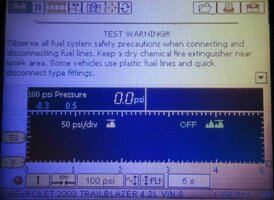

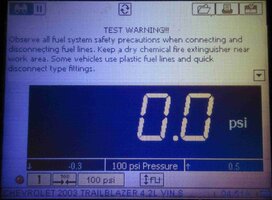

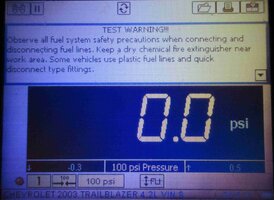

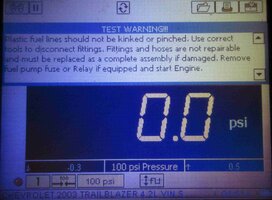

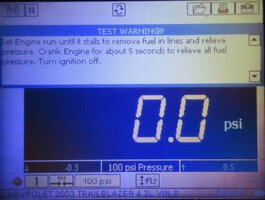

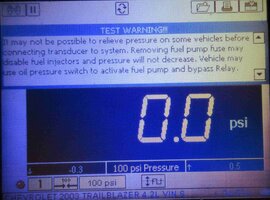

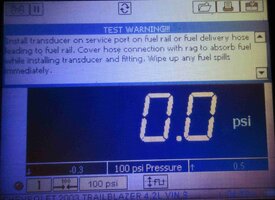

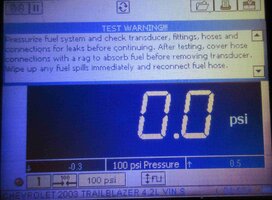

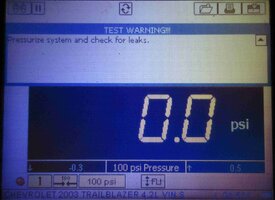

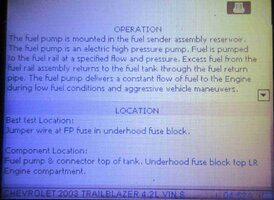

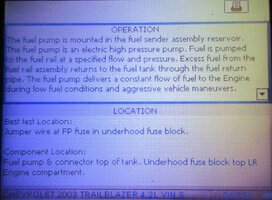

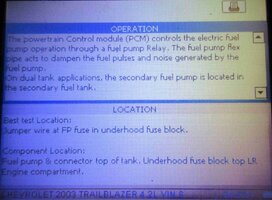

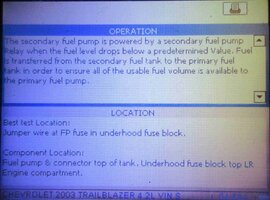

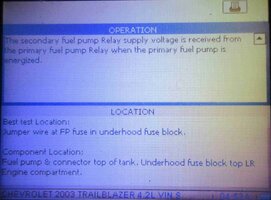

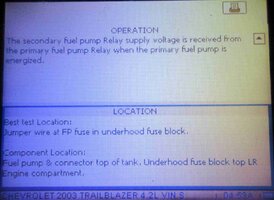

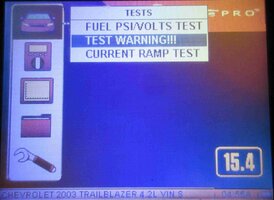

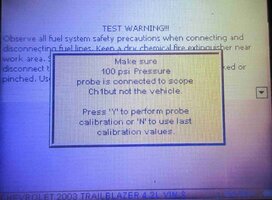

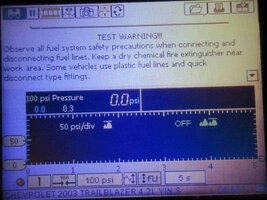

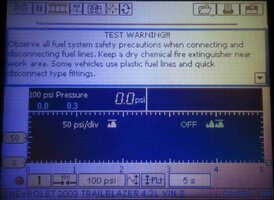

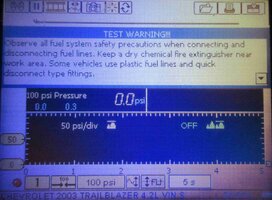

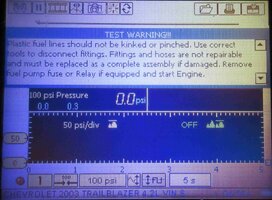

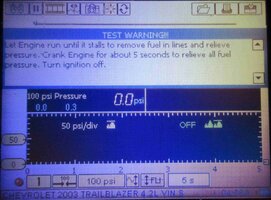

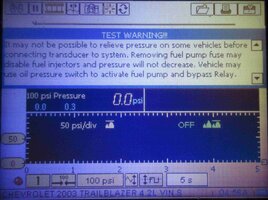

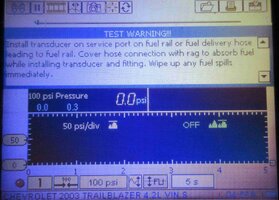

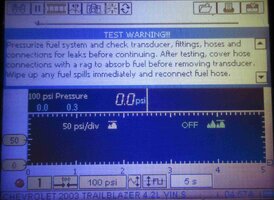

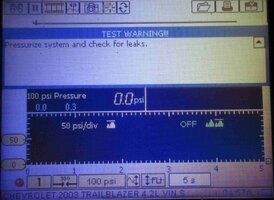

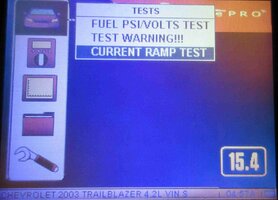

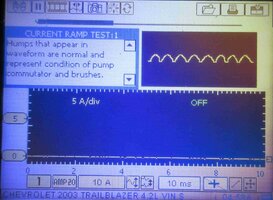

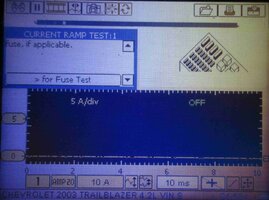

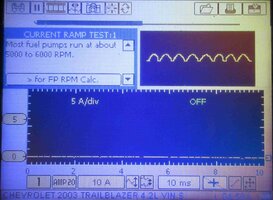

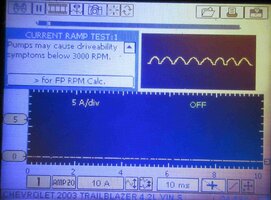

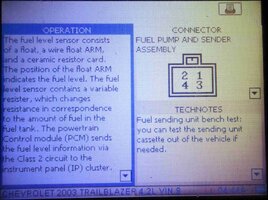

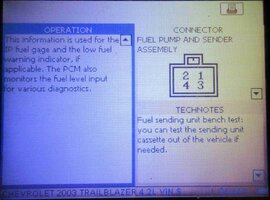

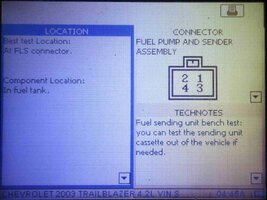

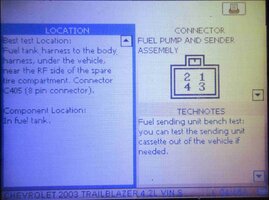

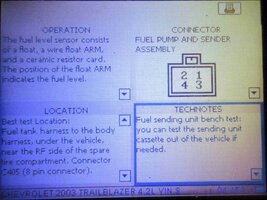

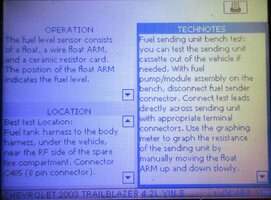

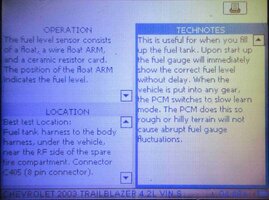

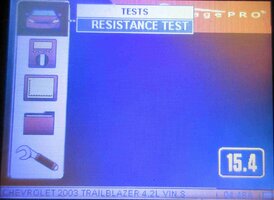

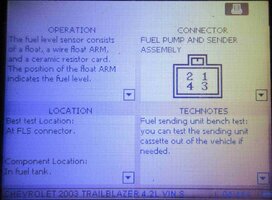

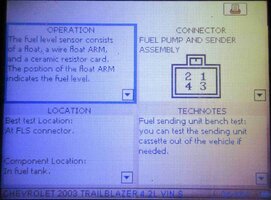

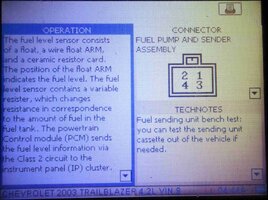

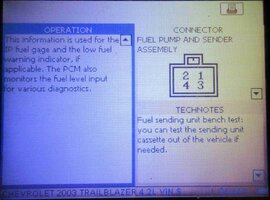

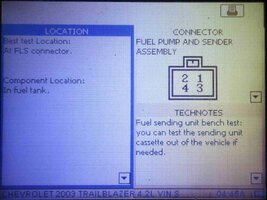

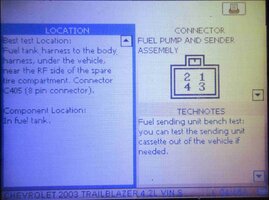

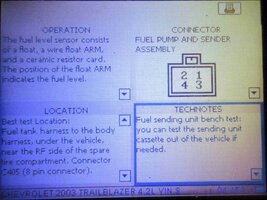

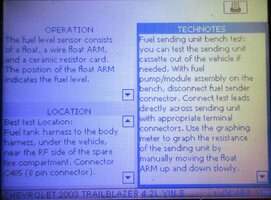

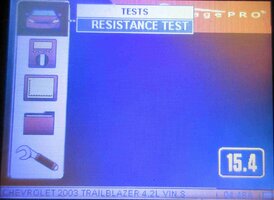

Just "Follow The Bouncing Ball" by Downloading, Saving and Referring to the Next Four Posts. Each Post will have 20 Screen Print Images as Attachments that I took off of my Snap-On Vantage PRO (Cropped Digital Photos) while covering the Diagnostics involved with the Fueling System Components in your 2003 Chevrolet Trailblazer with the 4.2L Engine.

These Images will Help You to Understand How the System Components Work... Where to Find their Important Locations in (and Underneath) the SUV and How to Connect Up your DMM or DVOM Probes and an Amp Clamp to Do ALL of these Diagnostics needed ... On Your Own.

Each Numbered Image is in the Sequence of what it would be like to hold the Snap-On Vantage in your OWN hands...and Just Follow Them ALL ...Frame By Frame By Frame .. For the Instructions Required.

These Screen Prints ONLY Involve the FUEL System of your SUV ...NOT the EVAP System...Which is a separate Topic and involves ANOTHER 80 or so Framed Images. But for now... Let's just concentrate on THESE 80 Images First:

Here are The First Twenty...

More to Follow...

(1) What Does the Failing System DO to Make the Vehicle Run Properly?

(2) Where are ALL of the System's Sub-Components within the Vehicle?

(3) How can I gain access to its Harnesses and Connectors so that Diagnostic Tools can be Hooked Up for Testing and Analyzing Each One?

(4) What are the EXPECTED Diagnostic Measurements for the System to Operate Normally?

Hmmm... THAT is all a LOT easier SAID than DONE...Right? Of course. Outside of Dealerships and Pro Shops, not many people have either the Sophisticated Diagnostic Equipment necessary or the Experience to use it all to run such Diagnostic Problems to Ground....Yes?

But Tonight is YOUR Lucky Night... Because I DO. :>)

Just "Follow The Bouncing Ball" by Downloading, Saving and Referring to the Next Four Posts. Each Post will have 20 Screen Print Images as Attachments that I took off of my Snap-On Vantage PRO (Cropped Digital Photos) while covering the Diagnostics involved with the Fueling System Components in your 2003 Chevrolet Trailblazer with the 4.2L Engine.

These Images will Help You to Understand How the System Components Work... Where to Find their Important Locations in (and Underneath) the SUV and How to Connect Up your DMM or DVOM Probes and an Amp Clamp to Do ALL of these Diagnostics needed ... On Your Own.

Each Numbered Image is in the Sequence of what it would be like to hold the Snap-On Vantage in your OWN hands...and Just Follow Them ALL ...Frame By Frame By Frame .. For the Instructions Required.

These Screen Prints ONLY Involve the FUEL System of your SUV ...NOT the EVAP System...Which is a separate Topic and involves ANOTHER 80 or so Framed Images. But for now... Let's just concentrate on THESE 80 Images First:

Here are The First Twenty...

More to Follow...

Last edited: