As I've officially reached wit's end, I'm back on this subject.

This problem is on a 199k mile 5.3 Envoy XL I picked up around the first of the year. The previous owner had reached the end of his rope with paying for repairs on it, and let it go for what I thought was a steal - a 5.3 Denali with a nearly immaculate leather interior, no check engine light and no obvious cobbling / mods. I brought it home and stored it for a bit, and then started replacing all the obvious stuff such as the driver side exhaust manifold that had been leaking so long the cast iron had rusted and eroded away from the #1 exhaust port and would never seal again. About $3500 later it was running and driving so well I decided to try getting the A/C working. Turns out the high side service valve (an $8 part) had leaked all the refrigerant out. I vacuumed it down and charged four cans of 134a and the A/C is still going strong three months later. Sweet?!?

All that aside, the issue I'm having ties back to this other thread by currently AWOL user Spck here. The reason I reference that is that the more I read of his initial posts the more I find in common with my issue.

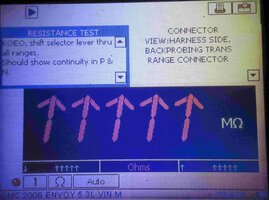

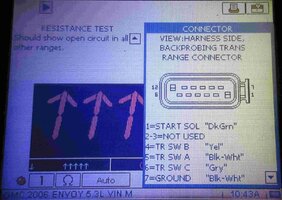

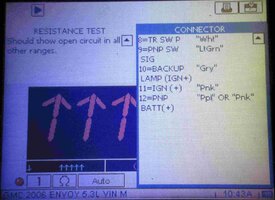

What happens is when the engine and / or transmission and / or underhood temp is in a certain range, that the PRNDL indicator in the IPC will randomly and intermittently jump from whatever gear is actually selected, to park, and then back to the selected gear. Obviously if it's in park nothing observable happens, but I have had it set a P0700 or P0604 code before even shifting out of park. Most of the time this phenomenon will occur when transitioning from stopped to moving or hitting a patch of pavement that unsettles the suspension to the driver's side, and other times it will happen for absolutely no apparent reason while in motion, with frequency decreasing as speed increases. But it will also occur when sitting motionless in neutral with no-one (including the driver) in or even near the vehicle.

When this problem occurs, a side effect is that the door locks will cycle from locked to unlocked and back to locked. This is how I have the BCM option set - lock doors when shifted out of park, unlock all doors when shifted into park. Since on the V8 models the only module capable of sensing and communicating what gear range the shifter is set to, the T42 TCM is undeniably the source of the erroneous information. Since it only connects to the ECM and ALDL connector over canbus, I don't think this issue could possibly be caused by problems on the older class 2 network. Side note: the door lock circuitry is not resposible for this issue. I will not reiterate this statement again. I've disabled the door lock options, and the only difference it made was that the problem was only easily perceptible when I happened to be looking at the PRNDL indicator, or was in motion and felt the transmission momentarily become as limp as a wet paper towel.

I won't demand that you go read what I've posted in the other 'Prndl going crazy' thread that was several years old when I hijacked it, but if you're so inclined please do - click here.

Here's a list of what troubleshooting / parts cannon steps I've taken, in chronological order (as well as my memory serves):

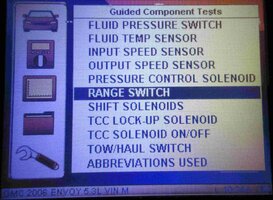

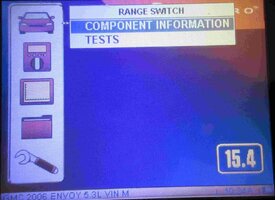

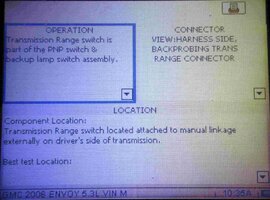

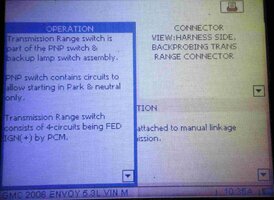

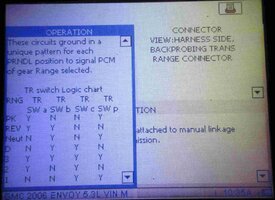

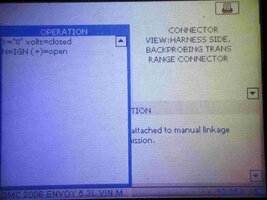

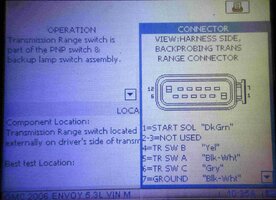

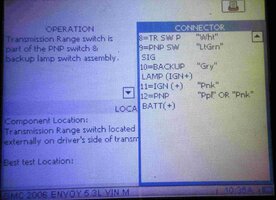

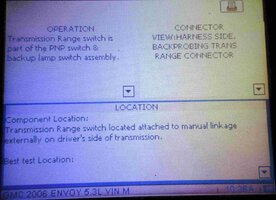

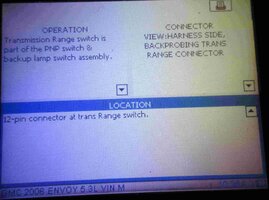

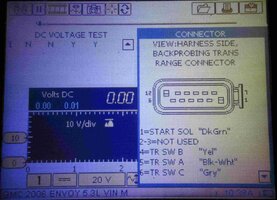

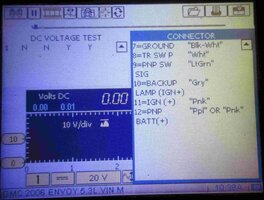

1) swapped the range switch (aka neutral safety switch) with a known good unit

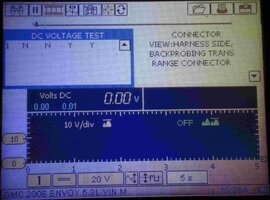

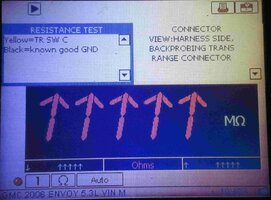

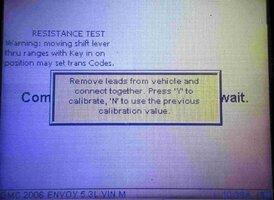

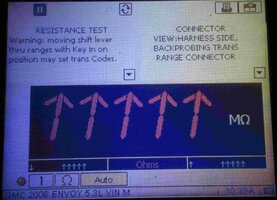

2) checked grounds / wiggled wires / harnesses and added an auxiliary ground to the case of the T42 module

3) split the under-hood fuseblock numerous times searching for any evidence of a cracked copper shunt

4) replaced the T42 module after the exiting module apparently developed a recalcitrant P0604 - Internal Control Module Random Access Memory Error

5) disconnected, stripped, inspected and re-loomed the branch of the wiring harness that goes over the back of the intake manifold and connects the transmission, lambda sensors and vss sensors

6) replaced the ignition switch

7) replaced the alternator

8) replaced the EPC solenoid, manifold pressure switch and internal transmission harness - I didn't replace the two a-b shift solenoids because this has happened while in every possible commanded gear

9) once again replaced the used T42 module with a re-programmed salvage module after what I refer to as 'the clicking incidents' worsened and became less temperature-dependent. The replacement module set a code on first start and even after clearing codes went into limp mode several times on a normal 115 mile commute circuit.

10) purchased a new GM 24252114 module and programmed it in-vehicle. It acted almost identically to the second salvage module

11) disconnected the purge canister vent solenoid power from the power circuit that supplies the TCM "always on" power

12) as I suspected the ground circuit to the range switch which passes through the underhood fuseblock may be goign open, I drove around waiting for it to start happening, and then switched to manual 2nd - the only condition where all circuits from the range switch to be open. It "clicked the locks" in second more than once.

13) I momentarily gave up and posted this

My guess here is that something is either causing loss of power to the T42 module which causes it to "reboot", or one of the inputs is causing it's internal programming to crash / watchdog, and cause it to (re-)start up in a state where it assumes the inputs should indicate the transmission controls and sensors suggest it's in park. Whatever the case, this module is one of two canbus enabled modules, so it can't "talk" directly to the IPC or BCM where the PRNDL indicator and door lock controls are being being leveraged.

Here's a video. Please let me know if you have trouble viewing it and I'll transcode. click

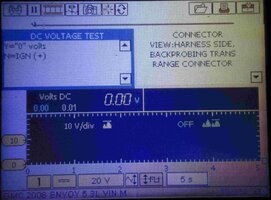

In the video, when I say "it's up to temperature", I mean it's up to the temperature where this symptom is easily reproduced. And when I say "there's 2nd", I mean I shifted into manual 2nd, the only gear selection where the range switch has all the pins open (i.e. not grounded) which would be equivalent to the ground wire to the range switch being open (broken).

I hope this is something stupid and remedial, but I'm going to come in saying it's a post-graduate level problem. In short, don't bother asking me about the health of the battery as it was bought new at the end of January (3 months old). Or how the transmission fluid looks as it would have zero bearing on such an obviously electrical problem. I've researched extensively and replaced or ruled out (to my satisfaction) all the usual offenders.

mrrsm: I appreciate you, but please keep your French vocabulary response down to the most basic (oui / non). I'm much better at decoding broken english.

This problem is on a 199k mile 5.3 Envoy XL I picked up around the first of the year. The previous owner had reached the end of his rope with paying for repairs on it, and let it go for what I thought was a steal - a 5.3 Denali with a nearly immaculate leather interior, no check engine light and no obvious cobbling / mods. I brought it home and stored it for a bit, and then started replacing all the obvious stuff such as the driver side exhaust manifold that had been leaking so long the cast iron had rusted and eroded away from the #1 exhaust port and would never seal again. About $3500 later it was running and driving so well I decided to try getting the A/C working. Turns out the high side service valve (an $8 part) had leaked all the refrigerant out. I vacuumed it down and charged four cans of 134a and the A/C is still going strong three months later. Sweet?!?

All that aside, the issue I'm having ties back to this other thread by currently AWOL user Spck here. The reason I reference that is that the more I read of his initial posts the more I find in common with my issue.

What happens is when the engine and / or transmission and / or underhood temp is in a certain range, that the PRNDL indicator in the IPC will randomly and intermittently jump from whatever gear is actually selected, to park, and then back to the selected gear. Obviously if it's in park nothing observable happens, but I have had it set a P0700 or P0604 code before even shifting out of park. Most of the time this phenomenon will occur when transitioning from stopped to moving or hitting a patch of pavement that unsettles the suspension to the driver's side, and other times it will happen for absolutely no apparent reason while in motion, with frequency decreasing as speed increases. But it will also occur when sitting motionless in neutral with no-one (including the driver) in or even near the vehicle.

When this problem occurs, a side effect is that the door locks will cycle from locked to unlocked and back to locked. This is how I have the BCM option set - lock doors when shifted out of park, unlock all doors when shifted into park. Since on the V8 models the only module capable of sensing and communicating what gear range the shifter is set to, the T42 TCM is undeniably the source of the erroneous information. Since it only connects to the ECM and ALDL connector over canbus, I don't think this issue could possibly be caused by problems on the older class 2 network. Side note: the door lock circuitry is not resposible for this issue. I will not reiterate this statement again. I've disabled the door lock options, and the only difference it made was that the problem was only easily perceptible when I happened to be looking at the PRNDL indicator, or was in motion and felt the transmission momentarily become as limp as a wet paper towel.

I won't demand that you go read what I've posted in the other 'Prndl going crazy' thread that was several years old when I hijacked it, but if you're so inclined please do - click here.

Here's a list of what troubleshooting / parts cannon steps I've taken, in chronological order (as well as my memory serves):

1) swapped the range switch (aka neutral safety switch) with a known good unit

2) checked grounds / wiggled wires / harnesses and added an auxiliary ground to the case of the T42 module

3) split the under-hood fuseblock numerous times searching for any evidence of a cracked copper shunt

4) replaced the T42 module after the exiting module apparently developed a recalcitrant P0604 - Internal Control Module Random Access Memory Error

5) disconnected, stripped, inspected and re-loomed the branch of the wiring harness that goes over the back of the intake manifold and connects the transmission, lambda sensors and vss sensors

6) replaced the ignition switch

7) replaced the alternator

8) replaced the EPC solenoid, manifold pressure switch and internal transmission harness - I didn't replace the two a-b shift solenoids because this has happened while in every possible commanded gear

9) once again replaced the used T42 module with a re-programmed salvage module after what I refer to as 'the clicking incidents' worsened and became less temperature-dependent. The replacement module set a code on first start and even after clearing codes went into limp mode several times on a normal 115 mile commute circuit.

10) purchased a new GM 24252114 module and programmed it in-vehicle. It acted almost identically to the second salvage module

11) disconnected the purge canister vent solenoid power from the power circuit that supplies the TCM "always on" power

12) as I suspected the ground circuit to the range switch which passes through the underhood fuseblock may be goign open, I drove around waiting for it to start happening, and then switched to manual 2nd - the only condition where all circuits from the range switch to be open. It "clicked the locks" in second more than once.

13) I momentarily gave up and posted this

My guess here is that something is either causing loss of power to the T42 module which causes it to "reboot", or one of the inputs is causing it's internal programming to crash / watchdog, and cause it to (re-)start up in a state where it assumes the inputs should indicate the transmission controls and sensors suggest it's in park. Whatever the case, this module is one of two canbus enabled modules, so it can't "talk" directly to the IPC or BCM where the PRNDL indicator and door lock controls are being being leveraged.

Here's a video. Please let me know if you have trouble viewing it and I'll transcode. click

In the video, when I say "it's up to temperature", I mean it's up to the temperature where this symptom is easily reproduced. And when I say "there's 2nd", I mean I shifted into manual 2nd, the only gear selection where the range switch has all the pins open (i.e. not grounded) which would be equivalent to the ground wire to the range switch being open (broken).

I hope this is something stupid and remedial, but I'm going to come in saying it's a post-graduate level problem. In short, don't bother asking me about the health of the battery as it was bought new at the end of January (3 months old). Or how the transmission fluid looks as it would have zero bearing on such an obviously electrical problem. I've researched extensively and replaced or ruled out (to my satisfaction) all the usual offenders.

mrrsm: I appreciate you, but please keep your French vocabulary response down to the most basic (oui / non). I'm much better at decoding broken english.

Last edited: