Hello to all,

I have a 2004 Trailblazer that I just finished rebuilding the head with valve job. The reason I took out the head was the exhaust manifold cracked and was making a loud sound so in trying to remove one bolt broke and I could not get it out for the life of me.

I had no codes from the leak, RPM was fine. I cleaned the throttle body, replaced gaskets etc. Put it all back and voila RPM goes to 900 for awhile then on his own back to 650.

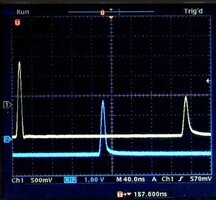

If I clear the codes and the PCM memory the RPM stays at 650 for a while and then when the RPM goes to 900 the P0171 pops up. I recorded PIDs and the STFT is up and down at idle it stays plus or minus 5 when I press the gas to take off it sometimes jumps to +17 to -10 then back and forth at 0 and at that range. Only goes thtat high when under load not cruising.

The LTFT also goes up on take off it went as high as 19 then it immediately stabilizes to +9 sometimes goes to 0 then 3 then back to 9. When I stop and idle it goes to 1.6 if idle is 650 or 2.6 if idle is 900. But it goes like that up and down all the time not slowly. The Bank one sensor 1 O2 sensor is going from 0.1 to 0.9 all the time, back and forth.

Bank one sensor 2 it sometimes stays at 0.8 to 0.7 and then it sometimes drops to 0.2 and 0.3 and back up. It's not supposed to do that is it? temps stay at 197 when driving and 201 when idle. When going up the hill it went to 206.

Car drives fine. MAF goes to 40 something g/s on takeoff and down to 4 at idle. I have not changed these yet. Don't remember how old the O2s are, but not too old.

New radiator and Temp Sensor is new also thermostat is new, radiator new, fan new all AC Delco

The Mass Airflow sensor is not new.

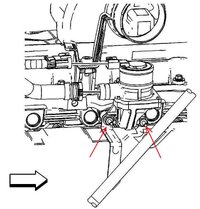

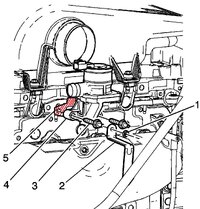

I bought a smoke machine and did the test and I had smoke come out from the 2 hoses that go to the SAIS. I did not install a plate yet to check if that could be the problem.

I did try to find a leak using a carb cleaner spray but did not notice anything.

The intake bolts are torqued to 89in/lb.

I am currently working on my son's 328i BMW and doing valve job and changing the head because of a stupid ass code caused by Vanos pressure being lost due to dumb German engineering and not knowing about it before doing a head swap 6 month ago. That head had the damage that causes the code, and it can only be fixed with a new head.

I need some opinions on the Chevy. I always ask for help when I am stuck. I read it all and watched most YouTube videos on this issue.

I do have a bidirectional Autel 708 scanner.

Thanks in advance for any help guys. Hope someone is still around driving these.

I have a 2004 Trailblazer that I just finished rebuilding the head with valve job. The reason I took out the head was the exhaust manifold cracked and was making a loud sound so in trying to remove one bolt broke and I could not get it out for the life of me.

I had no codes from the leak, RPM was fine. I cleaned the throttle body, replaced gaskets etc. Put it all back and voila RPM goes to 900 for awhile then on his own back to 650.

If I clear the codes and the PCM memory the RPM stays at 650 for a while and then when the RPM goes to 900 the P0171 pops up. I recorded PIDs and the STFT is up and down at idle it stays plus or minus 5 when I press the gas to take off it sometimes jumps to +17 to -10 then back and forth at 0 and at that range. Only goes thtat high when under load not cruising.

The LTFT also goes up on take off it went as high as 19 then it immediately stabilizes to +9 sometimes goes to 0 then 3 then back to 9. When I stop and idle it goes to 1.6 if idle is 650 or 2.6 if idle is 900. But it goes like that up and down all the time not slowly. The Bank one sensor 1 O2 sensor is going from 0.1 to 0.9 all the time, back and forth.

Bank one sensor 2 it sometimes stays at 0.8 to 0.7 and then it sometimes drops to 0.2 and 0.3 and back up. It's not supposed to do that is it? temps stay at 197 when driving and 201 when idle. When going up the hill it went to 206.

Car drives fine. MAF goes to 40 something g/s on takeoff and down to 4 at idle. I have not changed these yet. Don't remember how old the O2s are, but not too old.

New radiator and Temp Sensor is new also thermostat is new, radiator new, fan new all AC Delco

The Mass Airflow sensor is not new.

I bought a smoke machine and did the test and I had smoke come out from the 2 hoses that go to the SAIS. I did not install a plate yet to check if that could be the problem.

I did try to find a leak using a carb cleaner spray but did not notice anything.

The intake bolts are torqued to 89in/lb.

I am currently working on my son's 328i BMW and doing valve job and changing the head because of a stupid ass code caused by Vanos pressure being lost due to dumb German engineering and not knowing about it before doing a head swap 6 month ago. That head had the damage that causes the code, and it can only be fixed with a new head.

I need some opinions on the Chevy. I always ask for help when I am stuck. I read it all and watched most YouTube videos on this issue.

I do have a bidirectional Autel 708 scanner.

Thanks in advance for any help guys. Hope someone is still around driving these.