I have a small 5' x 8' utility trailer with a 3500 lb trailer. It's been SUPER useful. I've used to to move more thing than I can count. And usually you just fill it up and go. But sometimes you're loading it with really heavy stuff, like old asphalt, old concrete, dirt, gravel etc. Stuff that could potentially overload the trailer. So I need a way to weigh the trailer.

I was thinking a lot about this and I realized that if you can measure the distance between the axle and the bed of the trailer, so basically how much the suspension is compressing, you'd be able to calibrate that with some known weight (probably just water), and you'd be able to use that system to know pretty accurately how much weight you've put in there!

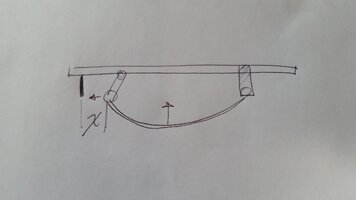

It sounds simple but implementing it is a little tricky. The best idea I can come up with is a small steel cable, like a bicycle shifter cable, that would connect to the axle, then run up to a pulley connected to the deck, then it would move laterally to the front of the trailer, go up the front and connect to a spring that would hold it right. Then put a mark or indicator on it and as the suspension compresses, the indicator would move.

I could use small threaded stainless steel eye bolts as the guides for the cable and a stainless steel cable and it should do pretty well and not bind up. I would need to welt a little tab onto the axle.

Another option would be an electronic device that could measure the distance, then I could calibrate it the same way and use my phone to read it. Although I like the fully mechanical solution better, it's so simple.

Has anyone ever made a system like this? Or some other simple system to measure how much cargo you are loading on to your trailer? I'll attach an image. The yellow arrow should move up as the trailer's suspension compresses - as you add weight to it. And it should go down as you remove the weight. And the amount should be consistent. I have plywood sides I put on there if I'm carrying loose material. I could put them on there, throw a blue tarp inside, and fill it up with water. If I used some kind of accurate flow meter on the hose, I'd know exactly how much weight I was adding. I could make marks every 250 lbs and I'd have a scale that would work great for telling when I'm approaching or over or way over the ideal 2000 lb payload limit.

I was thinking a lot about this and I realized that if you can measure the distance between the axle and the bed of the trailer, so basically how much the suspension is compressing, you'd be able to calibrate that with some known weight (probably just water), and you'd be able to use that system to know pretty accurately how much weight you've put in there!

It sounds simple but implementing it is a little tricky. The best idea I can come up with is a small steel cable, like a bicycle shifter cable, that would connect to the axle, then run up to a pulley connected to the deck, then it would move laterally to the front of the trailer, go up the front and connect to a spring that would hold it right. Then put a mark or indicator on it and as the suspension compresses, the indicator would move.

I could use small threaded stainless steel eye bolts as the guides for the cable and a stainless steel cable and it should do pretty well and not bind up. I would need to welt a little tab onto the axle.

Another option would be an electronic device that could measure the distance, then I could calibrate it the same way and use my phone to read it. Although I like the fully mechanical solution better, it's so simple.

Has anyone ever made a system like this? Or some other simple system to measure how much cargo you are loading on to your trailer? I'll attach an image. The yellow arrow should move up as the trailer's suspension compresses - as you add weight to it. And it should go down as you remove the weight. And the amount should be consistent. I have plywood sides I put on there if I'm carrying loose material. I could put them on there, throw a blue tarp inside, and fill it up with water. If I used some kind of accurate flow meter on the hose, I'd know exactly how much weight I was adding. I could make marks every 250 lbs and I'd have a scale that would work great for telling when I'm approaching or over or way over the ideal 2000 lb payload limit.