- Jul 24, 2012

- 822

Today on the drive home I noticed that when I come off the throttle, the voltage was frequently dropping into the 12 range.

Further information is that until yesterday (when I replaced 4 coil packs) I thought the volt meter was broken because it was reading super high ... and also the oil pressure gauge the needle is buried on the high side, and for a while the speedo wasn't working either, so I figured it was all the stepper motors going bad at once.

But after I replaced the coils, the needle settled in at just over 14.

Today, I was noticing the drop after I would get to the speed I wanted and then lifted my foot off the accelerator.

The coil packs are Duralast -- I wish I had been at a store with Delco, but I wasn't, but whatever they are new.

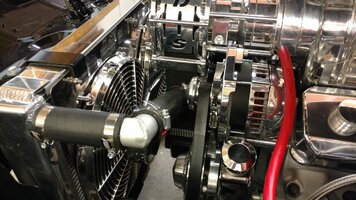

Battery is new as of three months ago. Alternator is a reman from O'Reilly that doesn't have many miles on it. There are a couple of threads out there, one is inconclusive but describes my issues in a way that sounds familiar, and the other has to do with extra sound equipment, which I don't have.

I suppose I should break out the multimeter but I don't actually know that I know how to use it.

Further information is that until yesterday (when I replaced 4 coil packs) I thought the volt meter was broken because it was reading super high ... and also the oil pressure gauge the needle is buried on the high side, and for a while the speedo wasn't working either, so I figured it was all the stepper motors going bad at once.

But after I replaced the coils, the needle settled in at just over 14.

Today, I was noticing the drop after I would get to the speed I wanted and then lifted my foot off the accelerator.

The coil packs are Duralast -- I wish I had been at a store with Delco, but I wasn't, but whatever they are new.

Battery is new as of three months ago. Alternator is a reman from O'Reilly that doesn't have many miles on it. There are a couple of threads out there, one is inconclusive but describes my issues in a way that sounds familiar, and the other has to do with extra sound equipment, which I don't have.

I suppose I should break out the multimeter but I don't actually know that I know how to use it.