I had to repair/splice the wires that power the vent valve after a tank drop gone wrong. So after I initially re-installed everything, I got the check gas cap (so i replaced it) then have had the P0455--large evap leak code ever since. I've paid it no mind until recently reading about how common the vent valve failure is and how simple it is to replace. For $18, I figured I could replace it with a new one, but now that I think back to my tank dropping misadventure, I'm wondering...

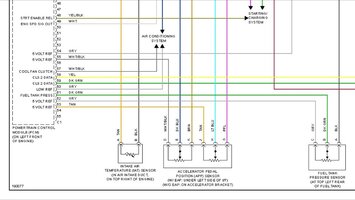

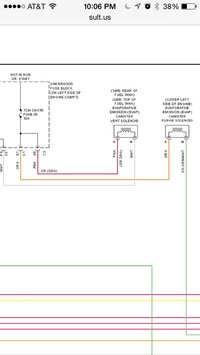

I'm not sure if the vent valve is getting power or if it's not working (or both). I disconnected the plug from the vent valve and stuck the lead into it and got a reading, but not sure what it should be?

I also checked the old vent valve for continuity (trying to rule out power supply as an issue). But I'm not sure it should/would give me a result if it was working or not working.

I guess i can just install the new vent valve, clear the code, and see what happens next. Worst case, i guess, is to drop the tank again and re-repair the power supply to the vent valve, but i'd like to avoid that at all costs. Then again, it could be something entirely different throwing this code, right? I'd say doubtful, but...

Any advice/suggestions/pointers/tips are much appreciated.

I'm not sure if the vent valve is getting power or if it's not working (or both). I disconnected the plug from the vent valve and stuck the lead into it and got a reading, but not sure what it should be?

I also checked the old vent valve for continuity (trying to rule out power supply as an issue). But I'm not sure it should/would give me a result if it was working or not working.

I guess i can just install the new vent valve, clear the code, and see what happens next. Worst case, i guess, is to drop the tank again and re-repair the power supply to the vent valve, but i'd like to avoid that at all costs. Then again, it could be something entirely different throwing this code, right? I'd say doubtful, but...

Any advice/suggestions/pointers/tips are much appreciated.

Return of the P0449.

Return of the P0449.