- Dec 4, 2011

- 568

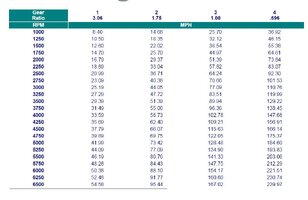

Has anyone with a programmer played with the A/C disable settings? I was hoping to find something based on TPS (my real problem is when trying to take off fast from a stoplight, but not WOT), but the only thing I can find is an RPM disable, which doesn't seem to actually be used. My stock settings are to cut off the A/C at 8000rpm, and re-enable at 7500. Does anyone have thoughts on more practical settings? Google found me some suggestions for the Silverado, using 4000/3000 but that seems like a pretty wide range at that low of rpm. Maybe 4000/3500 would be better?

FYI this is a daily-driver, and most of the time the A/C is used is either in town, or in rush-hour traffic, although obviously I don't want it to kick off at normal highway speeds. I guess the easiest solution might be to watch my rpm's and see what I would consider the high range for a cutoff, but I was hoping someone else may have already played with this on our platform.

FYI this is a daily-driver, and most of the time the A/C is used is either in town, or in rush-hour traffic, although obviously I don't want it to kick off at normal highway speeds. I guess the easiest solution might be to watch my rpm's and see what I would consider the high range for a cutoff, but I was hoping someone else may have already played with this on our platform.