- Dec 21, 2011

- 5

I copied information from several of my postings on the TrailVoy site into this new thread because I think the information will be useful to anyone towing a trailer.

The idea of using a code readout device (like the ScanGaugeII) to see the tranmission temperature is a very good idea, and should be considered before going to the trouble of installing a gauge. The ScanGaugeIIis also multi-purpose, reads codes and shows lots of data values..

But since I did not know about the ScanGaugeII 5 years ago, I put in a gauge. In case you (or others) are thinking of that, here are two pics of the transmission temperature gauge I mounted on my dashboard. I used sticky-back velcro so the annual inspection mechanic could move the gauge to get at the stickers. It does not look bad, IMO (but then, I'm an engineer with a function-over-form mindset .

.

View attachment 17361

View attachment 17360

I placed the sensor in the OUTGOING line TO the radiator. Did not have an aftermarket cooler at the time (I do now). Tow a camping trailer in summer, seldom get temp.s in the yellow (that's about 220 degF going TO the radiator). this year I changed all 12 or so quarts of fluid; plan to do that every 2 years.

The first two photos above show the gauge installation on the dashboard. The second two photos below show the hookup in the transmission cooling line. I chose to put the sensor in the HOT line going TO the transmission because I wanted to see the highest temperatures that the fluid experiences. These photos were taken about 3000 miles after re-doing the lines. (I had the cooling line rust through problem, separate threads about that issue.)

View attachment 17362

View attachment 17363

Photos show how poorly compression fittings do in this application. (It came with the gauge kit.) If it gets any messier, I will look for a better way...

The troubles experienced by myself and others with compression fittings in the transmission cooling lines are described in other posts on the Traivoy forum (may not have been copied to this forumm yet). Hope links below still work:

Transmission cooling line replacement (due to rust through issue):

http://forums.trailvoy.com/showthread.php?t=74948

Installation of auxiliary transmission fluid coolers. There are multiple threads on the subject, lots to read. Here's one to start:

http://forums.trailvoy.com/showthread.php?t=73742

If I recall correctly, the trouble with using brass compression fittings stems from the heat-up and cool-down each time the vehicle is used. The brass fitting and its ferrulls (rings) are a different material than the steel lines. The metals expand differently. Over time, this is thought to cause the leaking. Just tightening it risks stripping threads or twisting the steel line. When I tried tightening my fitting a few years after installing on the old, original lines, the line twisted, cracked and leaked more. I understand flare fittings are better, but a tool is needed to make the flare on a line you cut into.

On that _other_ forum, someone asked why my temperature was so high. My 220 degF is on the OUTGOING line TO the radiator and aux. cooler. I gives the hottest temperature in the system. I did that on purpose, because I read somewhere that if the fluid ever experiences temperatures above 250 degF or so it will burn. So seeing the temperature of the burnt-then-cooled fluid seemed less useful. If the actual burn temperature is not 250 degF, someone please post the correct value.

BTW, in December 2010 I received the Scangauge II OBDC code reader that others have mentioned as a present. If I had known of it 6 years ago, I would not have done the dashboard gauge. So now I will be able to get both temperatures: before cooling (on the dashboard gauge) and after cooling going back into the transmission - I think that is what the OBDC II reader will give me - If anyone knows better, please post.

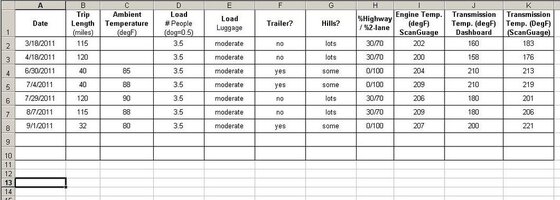

I created a spreadsheet to record BOTH values after making long trips. I will post that in this thread separately.

The idea of using a code readout device (like the ScanGaugeII) to see the tranmission temperature is a very good idea, and should be considered before going to the trouble of installing a gauge. The ScanGaugeIIis also multi-purpose, reads codes and shows lots of data values..

But since I did not know about the ScanGaugeII 5 years ago, I put in a gauge. In case you (or others) are thinking of that, here are two pics of the transmission temperature gauge I mounted on my dashboard. I used sticky-back velcro so the annual inspection mechanic could move the gauge to get at the stickers. It does not look bad, IMO (but then, I'm an engineer with a function-over-form mindset

.

.View attachment 17361

View attachment 17360

I placed the sensor in the OUTGOING line TO the radiator. Did not have an aftermarket cooler at the time (I do now). Tow a camping trailer in summer, seldom get temp.s in the yellow (that's about 220 degF going TO the radiator). this year I changed all 12 or so quarts of fluid; plan to do that every 2 years.

The first two photos above show the gauge installation on the dashboard. The second two photos below show the hookup in the transmission cooling line. I chose to put the sensor in the HOT line going TO the transmission because I wanted to see the highest temperatures that the fluid experiences. These photos were taken about 3000 miles after re-doing the lines. (I had the cooling line rust through problem, separate threads about that issue.)

View attachment 17362

View attachment 17363

Photos show how poorly compression fittings do in this application. (It came with the gauge kit.) If it gets any messier, I will look for a better way...

The troubles experienced by myself and others with compression fittings in the transmission cooling lines are described in other posts on the Traivoy forum (may not have been copied to this forumm yet). Hope links below still work:

Transmission cooling line replacement (due to rust through issue):

http://forums.trailvoy.com/showthread.php?t=74948

Installation of auxiliary transmission fluid coolers. There are multiple threads on the subject, lots to read. Here's one to start:

http://forums.trailvoy.com/showthread.php?t=73742

If I recall correctly, the trouble with using brass compression fittings stems from the heat-up and cool-down each time the vehicle is used. The brass fitting and its ferrulls (rings) are a different material than the steel lines. The metals expand differently. Over time, this is thought to cause the leaking. Just tightening it risks stripping threads or twisting the steel line. When I tried tightening my fitting a few years after installing on the old, original lines, the line twisted, cracked and leaked more. I understand flare fittings are better, but a tool is needed to make the flare on a line you cut into.

On that _other_ forum, someone asked why my temperature was so high. My 220 degF is on the OUTGOING line TO the radiator and aux. cooler. I gives the hottest temperature in the system. I did that on purpose, because I read somewhere that if the fluid ever experiences temperatures above 250 degF or so it will burn. So seeing the temperature of the burnt-then-cooled fluid seemed less useful. If the actual burn temperature is not 250 degF, someone please post the correct value.

BTW, in December 2010 I received the Scangauge II OBDC code reader that others have mentioned as a present. If I had known of it 6 years ago, I would not have done the dashboard gauge. So now I will be able to get both temperatures: before cooling (on the dashboard gauge) and after cooling going back into the transmission - I think that is what the OBDC II reader will give me - If anyone knows better, please post.

I created a spreadsheet to record BOTH values after making long trips. I will post that in this thread separately.