I apologize to the OP for hijacking his thread...

Gerbil21 - Thank you for replying - and to answer your questions -

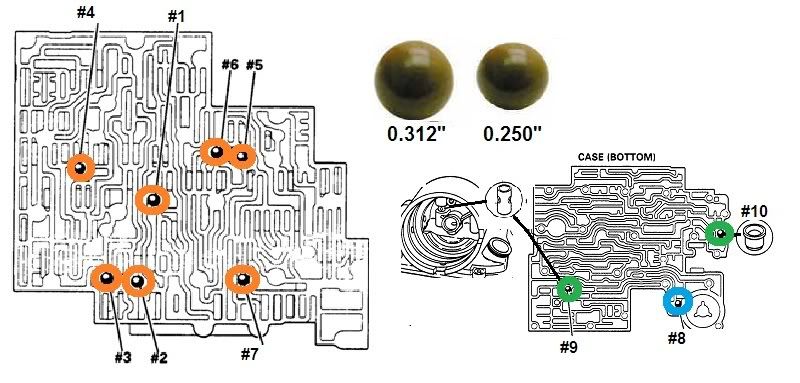

I have that exact kit, and - I have the torlon checkballs, too. I even have the blue trans assembly lube that that Hiram guy uses in the You Tube video (and I've watched that a few times, too).

I will probably skip the Vette servo; maybe come back to it later if I want to firm up the shifts further, as my only problem right now is a harsh 1-2 shift, and no codes (it actually slammed the 1-2 one day during the hot summertime last year in stop-n-slo traffic, until I turned on the heater to let the engine cool - it got up just past the 210 mark before I got smart and turned off the a/c and turned on the heater). I've got a new Derale stacked plate that I'm going to install after the TransGo kit, so that should help with the heat issue. My fluid is in like-new condition - but I have the feeling the previous owner started feeling the harsh 1-2, replaced the fluid, found the shift was the same, and ditched the truck (it's got about 135K on it now; I got it with 128K).

My 'new' fear, if you will, is staking the accumulator housings - I'm not a machinist, and I am a bit vague on that. If I understand correctly, you stake the housing to prevent the bearing from coming out of the housing - but looking at the pics in the article you referenced from offroadtb (and thank you for that) - it just looks like he used the chisel to tap 3 notches in the ridge of the bore - ? I'm not sure how that prevents the bearing from coming out, and I'm afraid of doing it incorrectly (it would help to understand the theory behind it, and then I'd be more sure that I did it correctly, of course). I even did a little side lookup project on 'staking the bearing' - and found favorable info on V-groove staking, etc - which looks like what the pics show - but, again, don't understand the purpose behind it, and want to make sure I do it right.

Other than that, I'm 'ok' with the rest of it (it'll take me longer than a day for sure, but I will be very careful with it).

As per "staking the bearing" all you are doing is making shure the bearing (which is around the same size as the check balls) Stays in the bore, you only have to place it on the bore and tap it in, once it won't go further tap it with the chisel.

from my understanding staking it in with a chisel will help it go further in since you hitting the whole bore and helping it to "fall in" for a lack of better wording. This is the same as when something is stuck in a pipe and you tap the outside, this works better then hitting the ball only since that will have more of a shoving action for the bore which under temperature changes it may loosen and overtime the bearing may come out.

Now as per the 1-2 shift do you have any slipping Or is it just a fast shift?

When I got my envoy it had around 132k and a real bad 1-2 slip and harsh engagement. After the shift kit was installed the slip was to a bare minimal (can't loose all slip since stock programming will call for slip to have a soft shift) but the 1-2 shift was a very fast harsh shift, it felt like someone hit the car in the rear. I drove it like this for a bit and adapted to it by lifting off the gas when it shifted to ease the shift.(also hard shifts aren't that bad on the trans, it saves clutches and bands by reducing shift times which in turn reduces slipping and heat, but overly hard shift can wear and or break hard parts like the sunshell or planateries)

I then went back and installed the vette servo and the transgo springs and made the mods to the stock parts as per transgo instructions (I did not install the spacer since I didn't drop the pan at the time and was having problems with reinstall). After the servo it shifted much better, it still had minimal slip but now just a small bump to the 1-2 shift, but it felt positive not draggy or harsh. The rest of the shifts are still smooth and you don't notice them with very minimal slip.

Also the transgo kit has the tcc pwm eliminator which makes Torque converter lockup very nice, engagement feels like a 5th gear. It does this by removing the pwm(pulse width modulation) part which basically makes it in to a on-off control rather then the stock partial engagement.

The pwm modulates the tcc (torque converter clutch) to a partial engagement in order to have smooth tcc apply and to apply it in lower gears and lower speeds. The stock tcc apply is fine but becomes a noticeable problem when you get a bumpy feel on the highway or rpm surge because of the tcc not being able to go 100% locked up since the bore in the valve body wares out. the pwm part of the tcc tries to apply and creates that feeling and the RPM to surge, that is why you would need to replace it.

I added the part about the tcc pwm in for you and the op, and to further my point of if you are unshure then you should read over all information you have at least twice and read up about it and understand what you are doing and why so when something happens youll actually understand why it's happening

And one more thing to help you understand and learn is a scan tool. Any cheap good rated Amazon obd2 scanner is just fine to see live data with the app I highly recommend "car gauge pro" (android) total cost for the scanner and app should be around $20. With the app you can see the transmissions tap cells. Tap cells are basically a x/y chart the PCM uses to calculate engine rpm/torque to trans. Line pressure for every shift, looking at the tap cells for the 1-2 shift will show you how much pressure it's adding when it shifts and give you a idea of wear on the trans. (Side note: this is how the trans. Keeps shift quality similar through out its life And compensates for wear in the trans.) Also seeing 1-2 shift time and 1-2 shift error will also give insight on whats happening. 1-2 shift time being the time the shift took and 1-2 shift error being the diffrence in time it took to shift versus the time the PCM commanded.

And I now have 145k, and shure don't drive like miss Daisy and i live in NYC but the fluid still looks and smells like new, so that's a big win for the transgo kit!