Ok guys (and gals), long time listener, first time poster. This is going to be a LONGGG post, so sit down, strap in, and get ready for some babbling.

Lets see where to start. I own Olson Kustom Works, we mainly do LSA swap parts for almost every LS platform on the planet. I have an extensive electronics and mechanical background, as well as the machining/manufacturing side of things (I mean, we make parts, so I hope I know what Im doing). I have 3 LSA powered GMT800s, and a 2650 powered GMT900 tahoe, but the GMT800 Suburban that i have been building for a few years is the one that has some fanciness that I need the GMTNation help with.

Heres a short list of mods done to this 2000 1500 4x4 chassis so far (not including most of the interior stuff), just so you know what Im working with here. This thing started life as a 5.3/4L60 4x4 model, and It got a little out of hand. I was going to swap all this 8 lug stuff into my 2000 Yukon, but I liked the condition of the Burb better.

Full Float DanaS70 (the 37 spline one) rear end out of a 2008 Dmax GMT680 van chassis, still kept the stock 4 link from the 1500

fabbed all 4 link brackets and heim panhard bar

Eaton Trutrac

9.25 2500 front diff and axles

built 4l80

stock 2005 2500HD Silverado 263HD Tcase

1410 Steel driveshafts

Stock Lq4, gapped rings, stock LSA cam

Ported SPS cathedral 317 heads, ARP head studs

Speed engineering headers, custom Ypipe, to 4" SS Magnaflow Catback

2500 front spindle swap, brakes, hubs, etc.

LSA blower, unported, 90mm TB, stock LSA balancer, 2.45 upper pulley, 16PSI at 2500rpm.

deka80s, stock intank pump, surge tank with twin 340s

efan conversion with 6 relays

battery relocation

Toyota Corolla radiator made into a heat exchanger

Stock Bosch IC pump

OKW Intercooler tank

Giant Derale trans cooler

Derale deep tube pan

OKW Rails

OKW Front Drive (8 rib belt)

OKW Phenolic Adapter Plates

OKW Phenolic Lid spacer

MT Classic Beadlocks custom powdercoated

BFG TA KOs

Pic For Attention

Where we started:

Now for the nitty gritty. Swapping to the 263 tcase. Well, I bought the 4L80, and the Tcase came with it, so I figured, how hard can it be to make it work right? Wrong. First issue is the shifting order is different than the 246 case. So when it says its in 2hi its actually in 4lo (actually killed a 4l80 just driving it around the parking lot like this). So that sucked. The 99-02 TCCM is a non-programmable unit (at least per the dealer), so finding a pre-03 263 TCCM was impossible, so I went with a 2004+ TCCM out of an Envoy, and sent it to Dmax Swap for them to flash it, since they have a standalone setup that will work with an ALLISON swap (note the lack of 4L80 there). The other issue is that the actuator on the tcase needs to be the new style 5 wire one without the internal brake, no biggie, rockauto had one in stock.

Got all the wiring swapped over to the 2005 Silverado diagrams per Mitchell1, key on, nothing. Some Google searches, the TCCM on the 263 wont even turn on until the engine is RUNNING. Ok, start engine. Hey, 2HI lit up (burb was on a lift at the time). Put it in gear, 2 rear wheels spin. Hit 4HI, HEY ALL 4 TIRES SPIN YAYYYY. Hit 4LO, light flashes. Crap. Emailed DMax Swap and the best guess they had was that the ECU (0411 PCM) wasnt sending the right Neutral/Park signal to the TCCM to allow it to shift into 4LO, as well as shift into N if I hold the buttons down. Not the END OF THE WORLD, since I may use 4LO once every 5 years (having 700hp you dont use 4LO often I wouldnt think). So driving in snow and mud in 4HI is still a VAST imporvement over 2HI anyday.

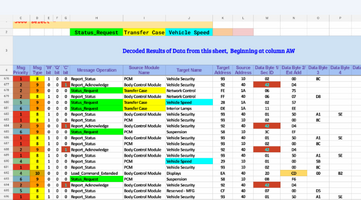

Now comes the fun part. Ive been messing with my OBD2 scanner/logger and trying to find PIDs and data for CURRENT GEAR SELECTED (which looks like 1114 or 1113 from another post I found), which would help me send the correct signal to the TCCM (which I would have to "sniff" from a Dmax ecu, easy), and use an Arduino with a J1850 converter to talk to it. But, theres another problem thats gonna pop up here. We are working on swapping this setup over to a Holley Terminator, with a 12.3 Pro Dash. So we were going to keep the ECU just to turn on the TCCM with serial data, but if it doesnt give the right shift position data, it seems like a giant waste of space. We already have an Arduino that is controlling the AC request from the body controls, turning on the AC compressor, and monitoring the AC pressure for duty cycle, so that part is handled as far as one of the big reasons that people say to keep the stock ECU in place. We also have the holley dash so we dont need to keep it for fuel gauge, etc. The ONLY thing we would now need it for it to turn on the TCCM.

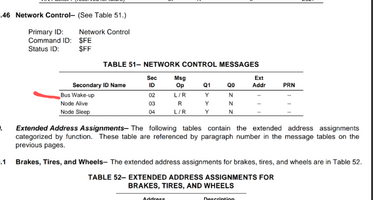

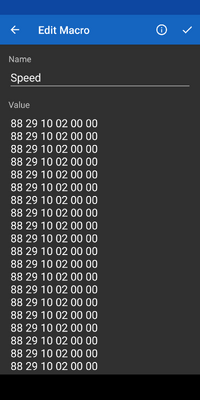

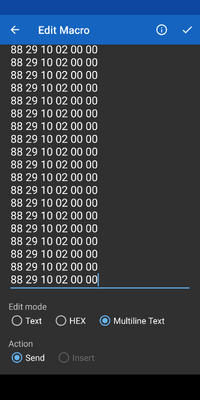

IF there is a way to "sniff the bus" and figure out the command being sent to the TCCM to turn it on, as well as find the command to send either/both a VSS and park position to the TCCM, I could theoretically delete the stock ECU, hook up a VSS, ACC and a P/N wire to the Arduino inputs, and send the commands to the TCCM as a standalone setup. I just have no idea where to start with getting or sending bus commands. I understand a fair bit about how the commands are being transmitted, but as some of these posts get farther into detail, I get lost.

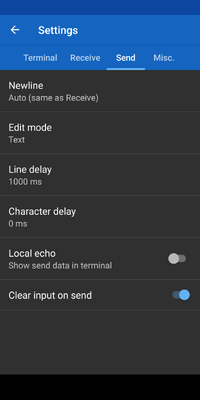

Im used to doing a lot of direct analog/digital stuff but bus commands are foreign to me. Ive been using my ELM327 module and a bluetooth serial console to send and receive buss messages and try to log bus traffic, but again its over my head at that point.

This is the stuff I normally try to build.

My other option is build a complete standalone controller in place of the TCCM, an arduino and a Hbridge and a night of coding would get it done, I just didnt want to go that route if I didnt HAVE to.

And no, im not swapping back to a 246 case or doing a manual conversion, so dont ask/say that.

This link was a HUGE help, but I think only condused me more, @TJBaker57 Ill be sending you a message here at some point.

gmtnation.com

gmtnation.com

Lets see where to start. I own Olson Kustom Works, we mainly do LSA swap parts for almost every LS platform on the planet. I have an extensive electronics and mechanical background, as well as the machining/manufacturing side of things (I mean, we make parts, so I hope I know what Im doing). I have 3 LSA powered GMT800s, and a 2650 powered GMT900 tahoe, but the GMT800 Suburban that i have been building for a few years is the one that has some fanciness that I need the GMTNation help with.

Heres a short list of mods done to this 2000 1500 4x4 chassis so far (not including most of the interior stuff), just so you know what Im working with here. This thing started life as a 5.3/4L60 4x4 model, and It got a little out of hand. I was going to swap all this 8 lug stuff into my 2000 Yukon, but I liked the condition of the Burb better.

Full Float DanaS70 (the 37 spline one) rear end out of a 2008 Dmax GMT680 van chassis, still kept the stock 4 link from the 1500

fabbed all 4 link brackets and heim panhard bar

Eaton Trutrac

9.25 2500 front diff and axles

built 4l80

stock 2005 2500HD Silverado 263HD Tcase

1410 Steel driveshafts

Stock Lq4, gapped rings, stock LSA cam

Ported SPS cathedral 317 heads, ARP head studs

Speed engineering headers, custom Ypipe, to 4" SS Magnaflow Catback

2500 front spindle swap, brakes, hubs, etc.

LSA blower, unported, 90mm TB, stock LSA balancer, 2.45 upper pulley, 16PSI at 2500rpm.

deka80s, stock intank pump, surge tank with twin 340s

efan conversion with 6 relays

battery relocation

Toyota Corolla radiator made into a heat exchanger

Stock Bosch IC pump

OKW Intercooler tank

Giant Derale trans cooler

Derale deep tube pan

OKW Rails

OKW Front Drive (8 rib belt)

OKW Phenolic Adapter Plates

OKW Phenolic Lid spacer

MT Classic Beadlocks custom powdercoated

BFG TA KOs

Pic For Attention

Where we started:

Now for the nitty gritty. Swapping to the 263 tcase. Well, I bought the 4L80, and the Tcase came with it, so I figured, how hard can it be to make it work right? Wrong. First issue is the shifting order is different than the 246 case. So when it says its in 2hi its actually in 4lo (actually killed a 4l80 just driving it around the parking lot like this). So that sucked. The 99-02 TCCM is a non-programmable unit (at least per the dealer), so finding a pre-03 263 TCCM was impossible, so I went with a 2004+ TCCM out of an Envoy, and sent it to Dmax Swap for them to flash it, since they have a standalone setup that will work with an ALLISON swap (note the lack of 4L80 there). The other issue is that the actuator on the tcase needs to be the new style 5 wire one without the internal brake, no biggie, rockauto had one in stock.

Got all the wiring swapped over to the 2005 Silverado diagrams per Mitchell1, key on, nothing. Some Google searches, the TCCM on the 263 wont even turn on until the engine is RUNNING. Ok, start engine. Hey, 2HI lit up (burb was on a lift at the time). Put it in gear, 2 rear wheels spin. Hit 4HI, HEY ALL 4 TIRES SPIN YAYYYY. Hit 4LO, light flashes. Crap. Emailed DMax Swap and the best guess they had was that the ECU (0411 PCM) wasnt sending the right Neutral/Park signal to the TCCM to allow it to shift into 4LO, as well as shift into N if I hold the buttons down. Not the END OF THE WORLD, since I may use 4LO once every 5 years (having 700hp you dont use 4LO often I wouldnt think). So driving in snow and mud in 4HI is still a VAST imporvement over 2HI anyday.

Now comes the fun part. Ive been messing with my OBD2 scanner/logger and trying to find PIDs and data for CURRENT GEAR SELECTED (which looks like 1114 or 1113 from another post I found), which would help me send the correct signal to the TCCM (which I would have to "sniff" from a Dmax ecu, easy), and use an Arduino with a J1850 converter to talk to it. But, theres another problem thats gonna pop up here. We are working on swapping this setup over to a Holley Terminator, with a 12.3 Pro Dash. So we were going to keep the ECU just to turn on the TCCM with serial data, but if it doesnt give the right shift position data, it seems like a giant waste of space. We already have an Arduino that is controlling the AC request from the body controls, turning on the AC compressor, and monitoring the AC pressure for duty cycle, so that part is handled as far as one of the big reasons that people say to keep the stock ECU in place. We also have the holley dash so we dont need to keep it for fuel gauge, etc. The ONLY thing we would now need it for it to turn on the TCCM.

IF there is a way to "sniff the bus" and figure out the command being sent to the TCCM to turn it on, as well as find the command to send either/both a VSS and park position to the TCCM, I could theoretically delete the stock ECU, hook up a VSS, ACC and a P/N wire to the Arduino inputs, and send the commands to the TCCM as a standalone setup. I just have no idea where to start with getting or sending bus commands. I understand a fair bit about how the commands are being transmitted, but as some of these posts get farther into detail, I get lost.

Im used to doing a lot of direct analog/digital stuff but bus commands are foreign to me. Ive been using my ELM327 module and a bluetooth serial console to send and receive buss messages and try to log bus traffic, but again its over my head at that point.

This is the stuff I normally try to build.

My other option is build a complete standalone controller in place of the TCCM, an arduino and a Hbridge and a night of coding would get it done, I just didnt want to go that route if I didnt HAVE to.

And no, im not swapping back to a 246 case or doing a manual conversion, so dont ask/say that.

This link was a HUGE help, but I think only condused me more, @TJBaker57 Ill be sending you a message here at some point.

More PIDs for Torque App

Hi guys, after readying trought all those page i would need some help finding my own pid ? could you guys help me ?. basicaly im trying to find current gear and oil pressure on a 2004 silverado. those are specific gm pid. ive gone many way but still cant get anything to work. right now im...