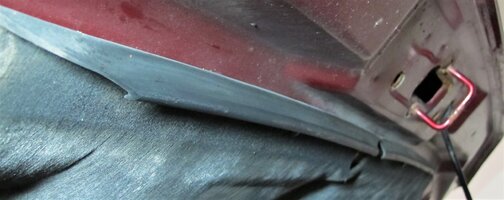

I pulled the coil on #2. Just because it's easy to reach and I'm learning my way around. There's a collection of red debris that settled around the sides of the spark plug.

The camera wouldn't focus. It's a reddish fine crystal (like sugar) and it breaks up into a fine powder if you rub it between your fingers. (way down there next to the plug)

There's also some reddish stuff on the collar of the rubber coil boot. Does anyone know what's going on here?

The plug also has some problems. It's an ACDelco 41-981, with discoloration and corrosion. This is maybe an original plug and I doubt that the coil has ever been removed either (140,000 miles.)

The camera wouldn't focus. It's a reddish fine crystal (like sugar) and it breaks up into a fine powder if you rub it between your fingers. (way down there next to the plug)

There's also some reddish stuff on the collar of the rubber coil boot. Does anyone know what's going on here?

The plug also has some problems. It's an ACDelco 41-981, with discoloration and corrosion. This is maybe an original plug and I doubt that the coil has ever been removed either (140,000 miles.)