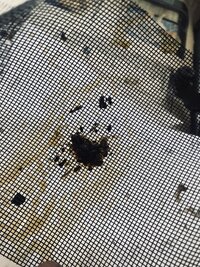

In another thread, Mooseman commented on a post I made about severe sludge I had in my 4.2. I broke most of it up and cleaned/vacuumed it plus cleaned the oil pan and pickup. The pickup wasn't severely clogged but could use cleaning.

Put it back together with a mechanical gauge (uses tube, not sender) and oil pressure will dip to 0 when it's hot. Instrument cluster gauge agrees ("stop engine"). So this is not a gauge problem as most threads end up covering.

I'm testing this engine hoping to use it in another Envoy but won't put forth the effort until I am confident in it.

What is mysterious is it can idle for an hour at 20 psi but if I drive it then it will start dropping the oil pressure. Shift to N and restart it and immediately back to 20+ psi. If it were purely mechanical issue causing the low oil pressure (such as worn bearings) then seems it should remain low oil pressure.

I swapped a VVT solenoid into it hoping it may be a factor but same result. I can rev the engine and that doesn't always increase oil pressure. No weird noises however I don't let it run for but a few seconds at 0 psi. Restarting fixes low oil pressure.

Question: Do you think random sludge particles are clogging the system and stopping oil flow and restarting frees them and restores oil pressure since it seems vehicle movement is needed to initiate the problem?

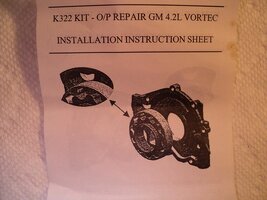

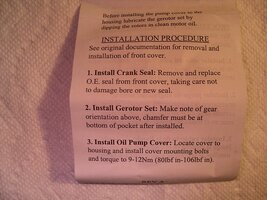

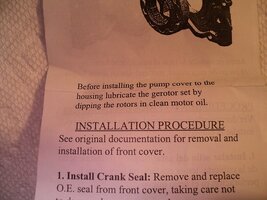

I'm looking for ideas on anything to try. Engine wear and sludge are both in play here and both would be fatal (not worth fixing). One thing I did not do was replace the o-ring on the oil pickup or touch the oil pump when I took the timing cover off. MSSRM commented those are factors so I'm deciding if it's worth diving back in to change those. Labor is free so I'm not afraid of the work but I'm not interested throwing more than $100 at it vs using that towards a new engine.

Thanks!

Put it back together with a mechanical gauge (uses tube, not sender) and oil pressure will dip to 0 when it's hot. Instrument cluster gauge agrees ("stop engine"). So this is not a gauge problem as most threads end up covering.

I'm testing this engine hoping to use it in another Envoy but won't put forth the effort until I am confident in it.

What is mysterious is it can idle for an hour at 20 psi but if I drive it then it will start dropping the oil pressure. Shift to N and restart it and immediately back to 20+ psi. If it were purely mechanical issue causing the low oil pressure (such as worn bearings) then seems it should remain low oil pressure.

I swapped a VVT solenoid into it hoping it may be a factor but same result. I can rev the engine and that doesn't always increase oil pressure. No weird noises however I don't let it run for but a few seconds at 0 psi. Restarting fixes low oil pressure.

Question: Do you think random sludge particles are clogging the system and stopping oil flow and restarting frees them and restores oil pressure since it seems vehicle movement is needed to initiate the problem?

I'm looking for ideas on anything to try. Engine wear and sludge are both in play here and both would be fatal (not worth fixing). One thing I did not do was replace the o-ring on the oil pickup or touch the oil pump when I took the timing cover off. MSSRM commented those are factors so I'm deciding if it's worth diving back in to change those. Labor is free so I'm not afraid of the work but I'm not interested throwing more than $100 at it vs using that towards a new engine.

Thanks!

![IMG_E9961[1].JPG](/forums/data/attachments/149/149741-685abc3f5f5b020a099f1d0e4f27c6fb.jpg)